Refuse-derived fuel based on combustible components of domestic refuse and preparation method thereof

A technology of domestic waste and derived fuels, applied in the fields of environmental protection and energy, can solve the problems of high energy consumption, low calorific value, and low calorific value of derived fuels in the preparation process, and achieve the effects of easy storage and transportation, stable combustion and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In this embodiment, the composition and weight percentage ratio of a derived fuel based on the combustible components of domestic waste is: 65% of combustible components of domestic waste, 30% of bituminous coal, 2.5% of calcium oxide, 1.5% of industrial cornstarch, Sodium Humate 1.0%. The preparation steps are as follows:

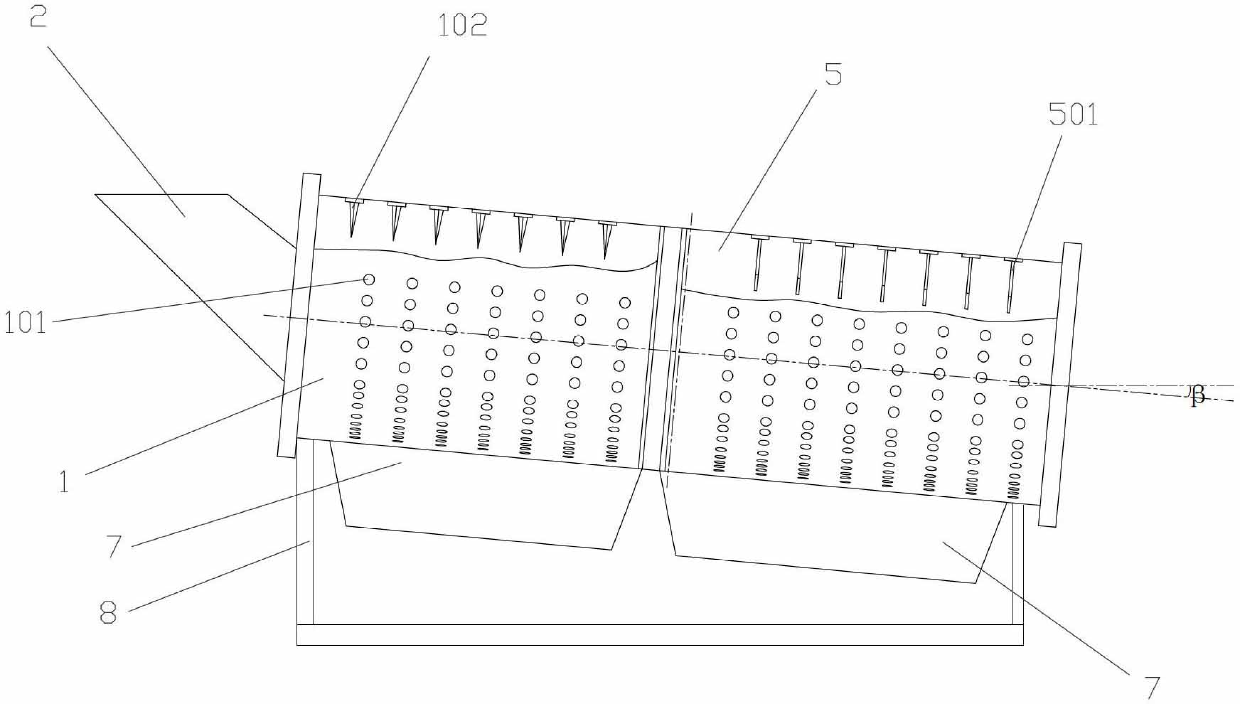

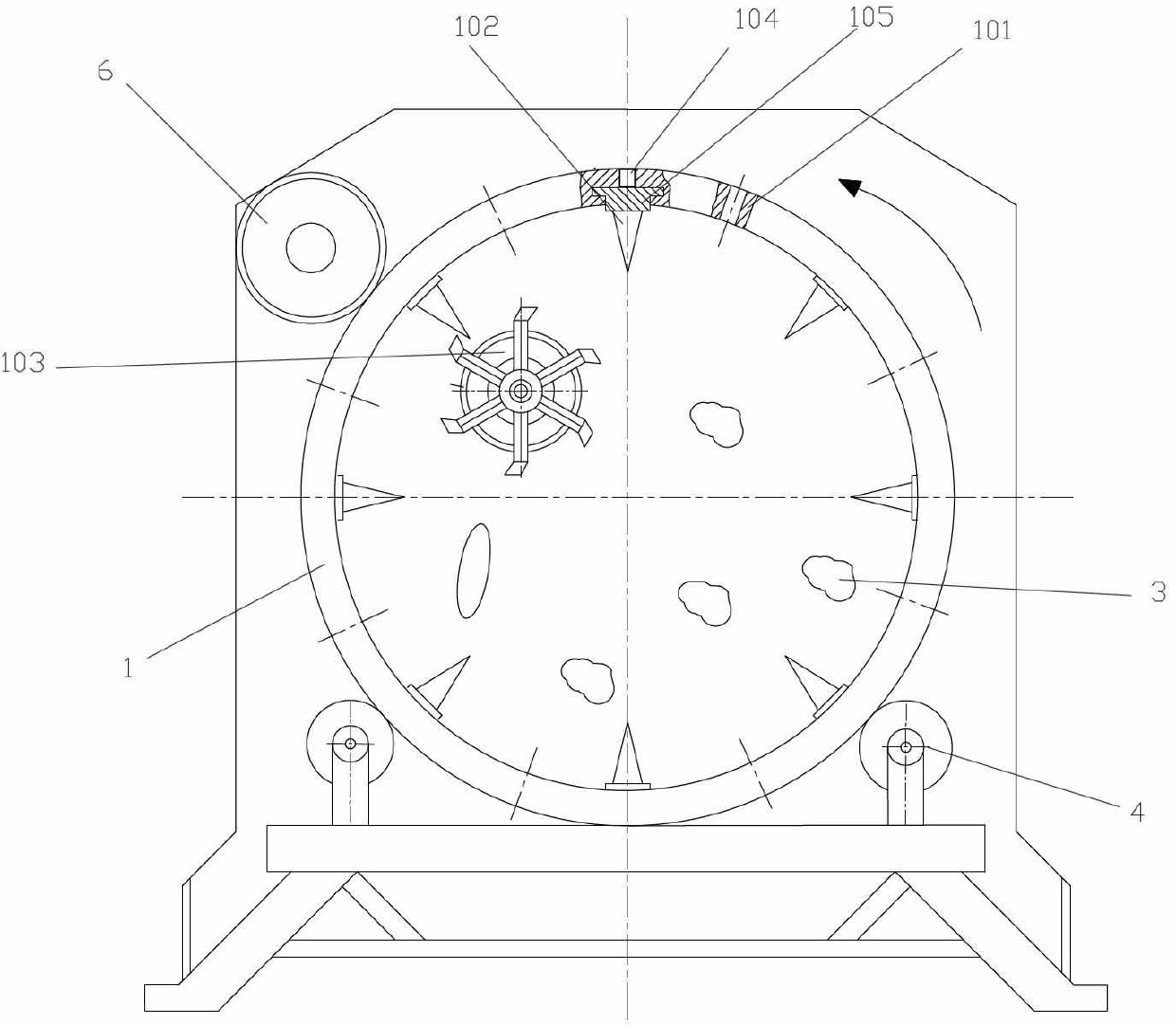

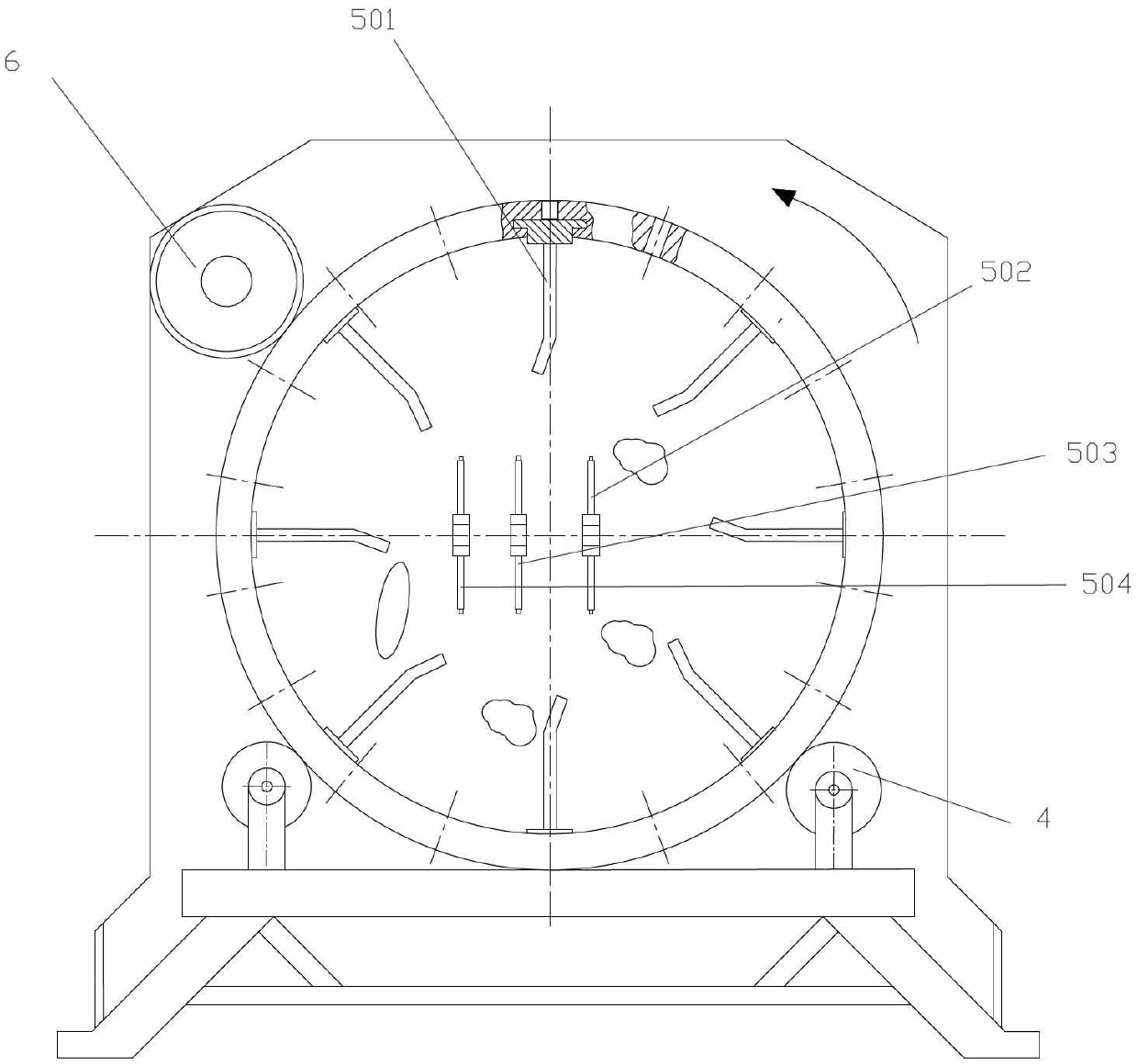

[0072] (1) Separating municipal solid waste into long strips of plastics and textiles through two-stage trommel bag breaking and hanging, and then separating plastics, waste paper and For textile fragments, the double air chamber multi-functional air separator separates plastics, waste paper and textile fragments, and after further air separation, the combustible components of domestic waste composed of waste paper and textiles are separated;

[0073] (2) Use a rotary dryer to dry the combustible components of domestic garbage at a drying temperature of 200°C to reduce the moisture content to 25%;

[0074] (3) Use a shear crusher to crush the comb...

Embodiment 2

[0087] In this embodiment, the components and proportions of the garbage-derived fuel are: 70.0% (weight %) of domestic waste combustible components, 25.0% (weight %) of bituminous coal, 2.0% (weight %) of calcium oxide, industrial cornstarch 2.0% (weight %), sodium humate 1.0% (weight %). The drying temperature of the preparation step (2) is 250° C., the preparation step (4) is stored for 12 minutes, and the other steps are the same as in Example 1.

Embodiment 3

[0089] In this embodiment, the components and proportions of the refuse-derived fuel are: 74% (weight %) of domestic waste combustible components, 21.5% (weight %) of bituminous coal, 1.0% (weight %) of calcium oxide, industrial cornstarch 2.5% (weight %), sodium humate 1.0% (weight %). The drying temperature of the preparation step (2) is 300° C., the preparation step (4) is stored for 15 minutes, and the other steps are the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap