Tool type support for mounting composite slabs

An installation and tool-type technology, applied in the on-site preparation of pillars and building components, construction, etc., can solve the problems of poor comprehensive economic benefits, uneconomical addition of ribs, and inability to fully exert the bearing capacity of laminated plate components. The effect of avoiding concrete cracking, avoiding extensive use, and good out-of-plane balance recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

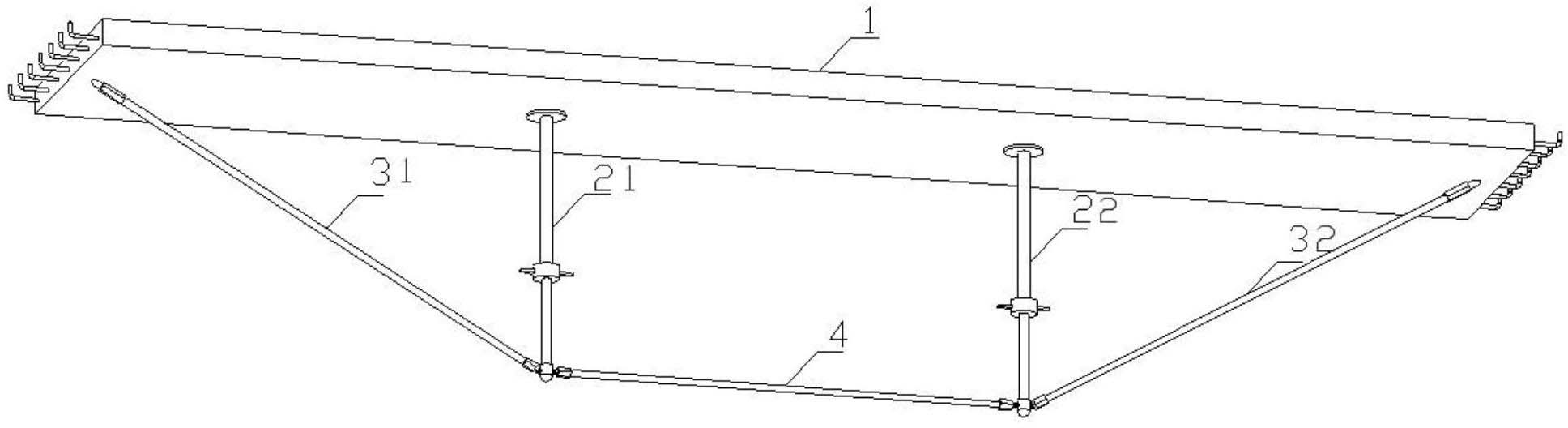

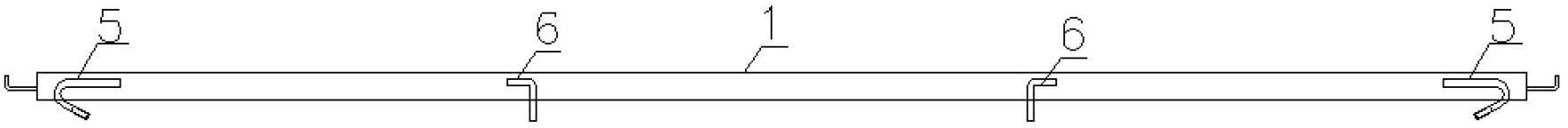

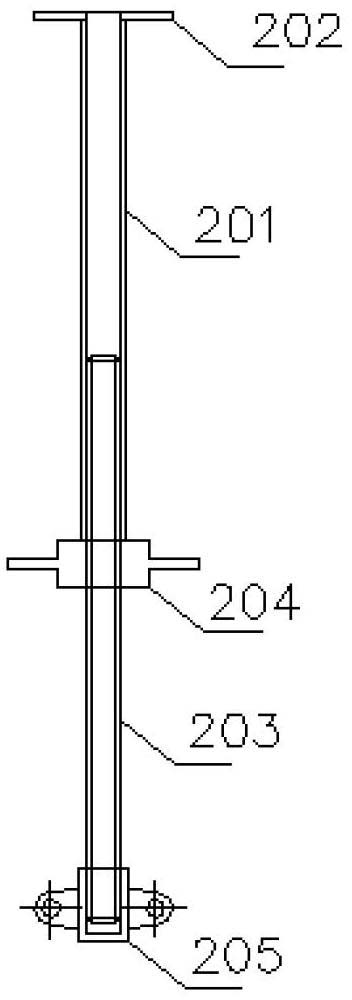

[0022] A tool-type support for the installation of a laminated board, comprising: a horizontal tie rod 4, a first oblique tie rod 31 and a first vertical support rod 21 are detachably connected to one end of the horizontal tie rod 4 and connected to the first oblique tie rod 31 respectively It is connected with one end of the first vertical support rod 21, and the second oblique tie rod 32 and the second vertical support rod 22 are detachably connected to the other end of the horizontal tie rod 4 and connected with the second oblique tie rod 32 and the second vertical support rod 22 respectively. One end of the vertical support rod 22 is connected, and the first vertical support rod 21 and the second vertical support rod 22 adopt adjustable support rods, and the described adjustable support rods include sleeve pipe 201 and screw rod 203, and the screw rod 203 is threaded An adjusting nut 204 is connected, and one end of the sleeve 201 is sleeved on the screw rod 203 and support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com