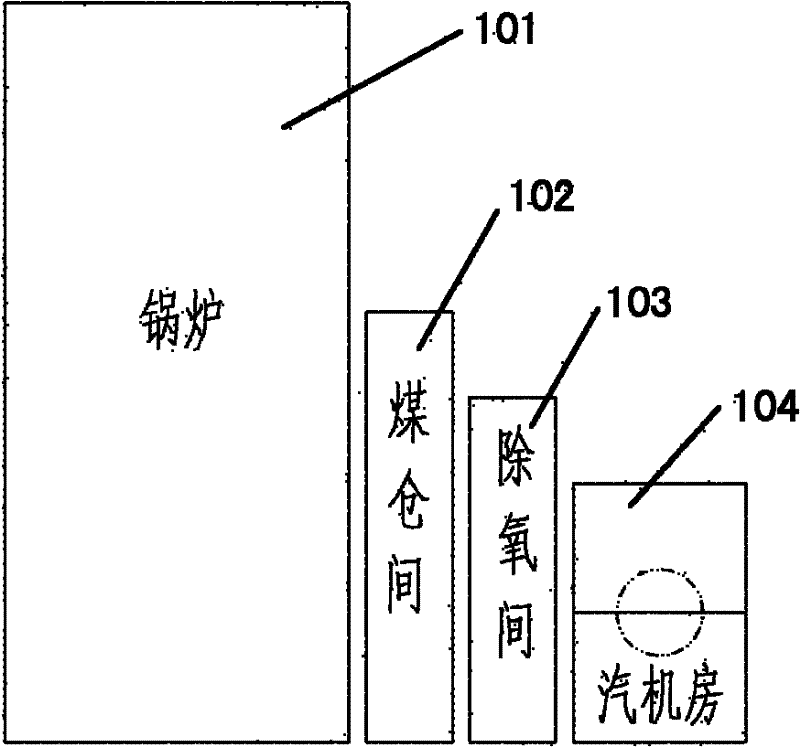

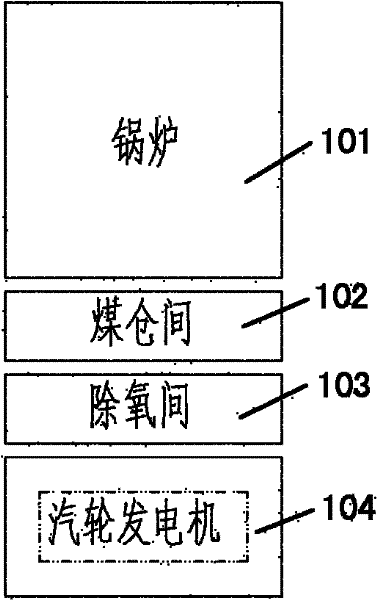

Main plant with steam turbine generator arranged on high level

A technology of steam turbine generator and steam turbine generator set, which is applied in industrial buildings and other directions, can solve the problems of reducing the cost of high-temperature piping, increasing the cost of civil construction, and long distance of high-temperature interfaces, and achieves improved normal operation efficiency and good investment income. , the effect of shortening the distance between the high temperature interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will now be described in detail with reference to the drawings.

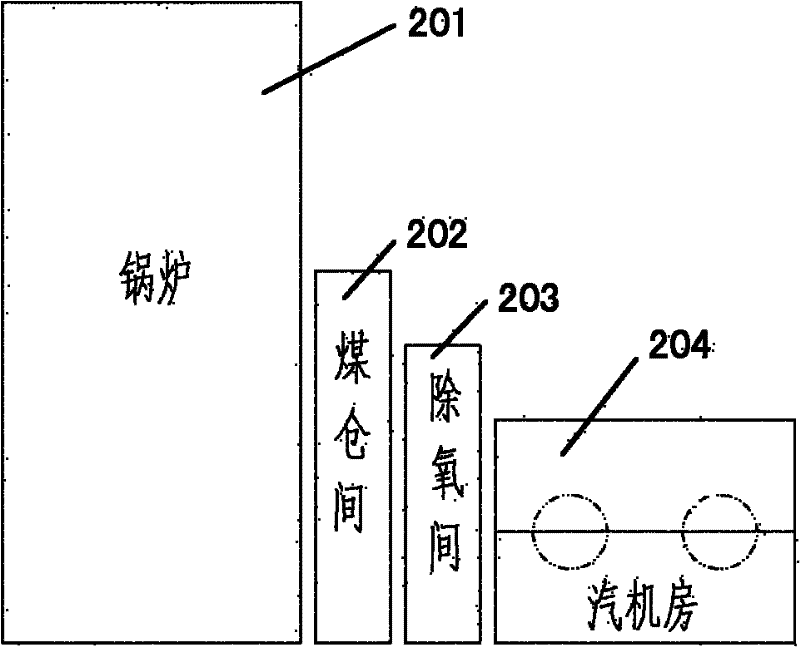

[0039] Figure 3a with Figure 3b It shows the main building of the single-shaft high-position turbine generator according to the present invention.

[0040] In this embodiment, the main plant of the high-level arrangement of the steam turbine generator of the present invention mainly includes: a boiler room 301, a deaeration coal bunker integrated frame 302, and a high-level turbine room 303. The deaeration coal bunker integrated frame 302 is composed of a combination of a deaeration room and a coal bunker room and is arranged next to one side of the boiler 301. In addition, as shown in the figure, the high-level steam engine room 303 is installed on the upper part of the integrated frame 302 of the deaeration coal bunker. The single-shaft steam turbine generator is arranged in the high-level turbine room 303. The base can be arranged on the main beam of the integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com