Air compression buffering device

A buffer device and air compression technology, which is applied in reducing greenhouse gases, climate sustainability, hydroelectric power generation, etc., and can solve problems such as oil pollution, stuck on the piston, and water entering the valve port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

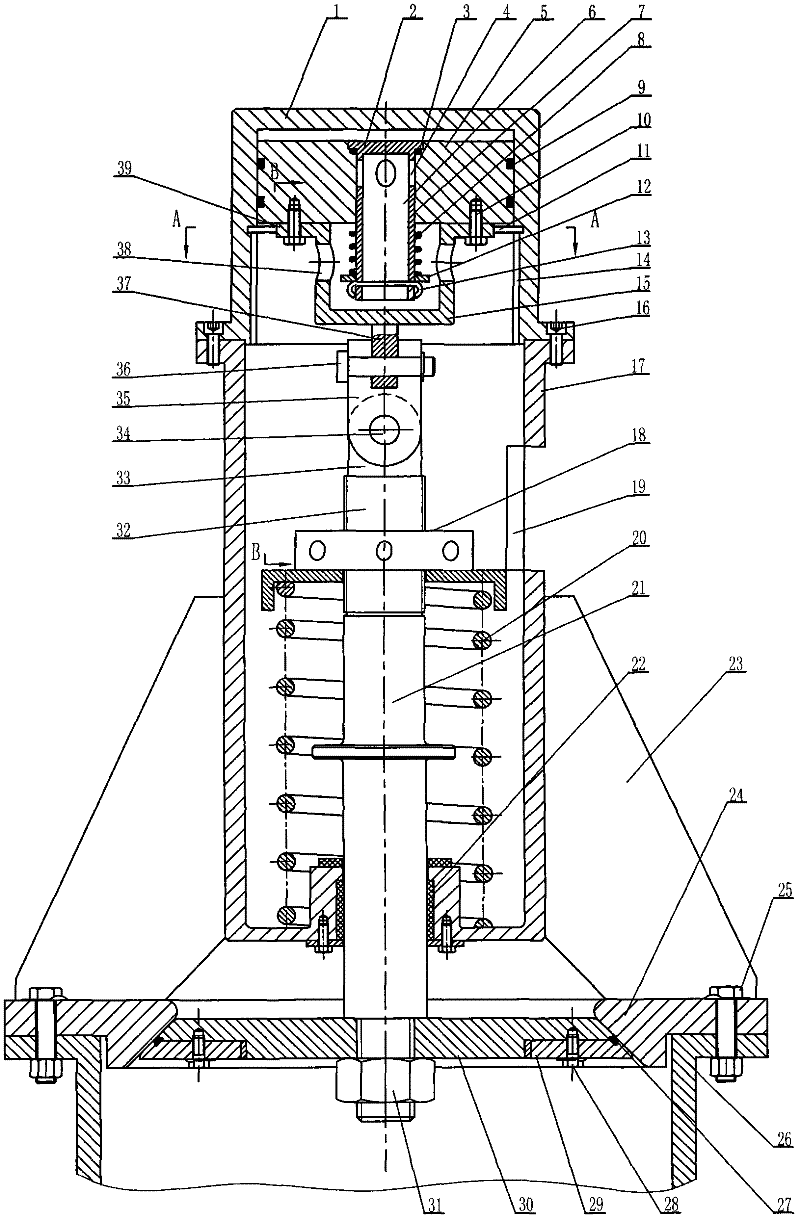

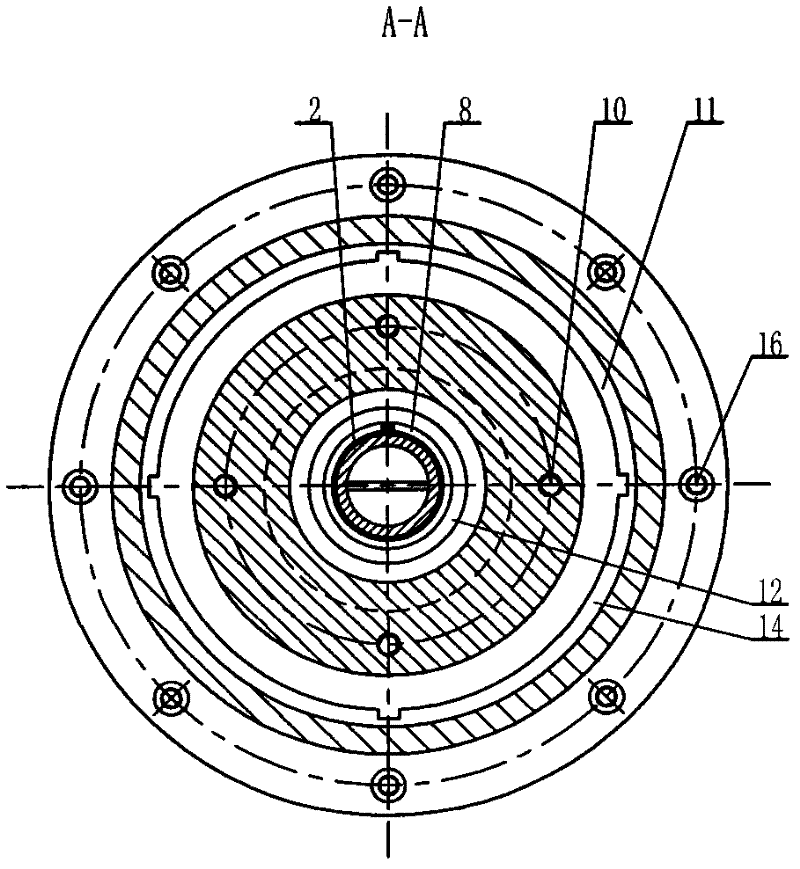

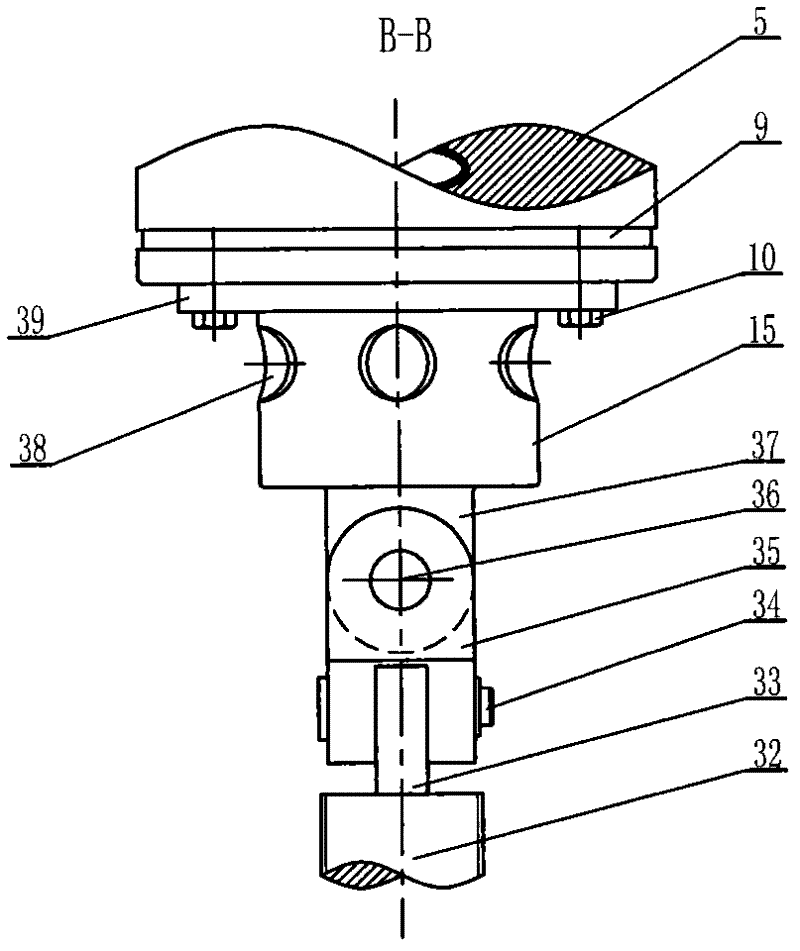

[0012] Put the stop valve O-ring (3) on the upper end of the reverse cut-off hollow valve (2) with 2 to 4 upper air inlet holes (4) and the air inlet pipe (6), and then put the reverse cut-off hollow valve (2 ) into the central guide hole (7) of the buffer piston (5), and can slide up and down freely. Put the cut-off valve spring (8) on the lower end of the reverse cut-off hollow valve (2), then install the retaining ring (12) on the lower end of the stop valve spring (8), and reverse the cut-off hollow valve ( 2) Fix the upper stop ring stop pin (13). Have 2~4 side air intake holes (38) on the outer surface of hole type fixed head (15), there is fixed head to connect orifice plate (37) below hole type fixed head (15), fix bolt (10) with piston The hole type fixed head (15) is fixed on the lower end of the buffer piston (5) through the connecting flange (39), and two oil storage ring grooves (9) are opened on the outer surface of the buffer piston (5). Connect the fixed head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com