Real-time measurement device for measuring outer diameter of steel pipe

A real-time measurement, measuring instrument technology, applied in the direction of mechanical diameter measurement, can solve the problems of cumbersome manual operation, large deviation, difficult to ensure the quality of steel pipes, etc., to achieve the effect of improving work efficiency, high precision and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

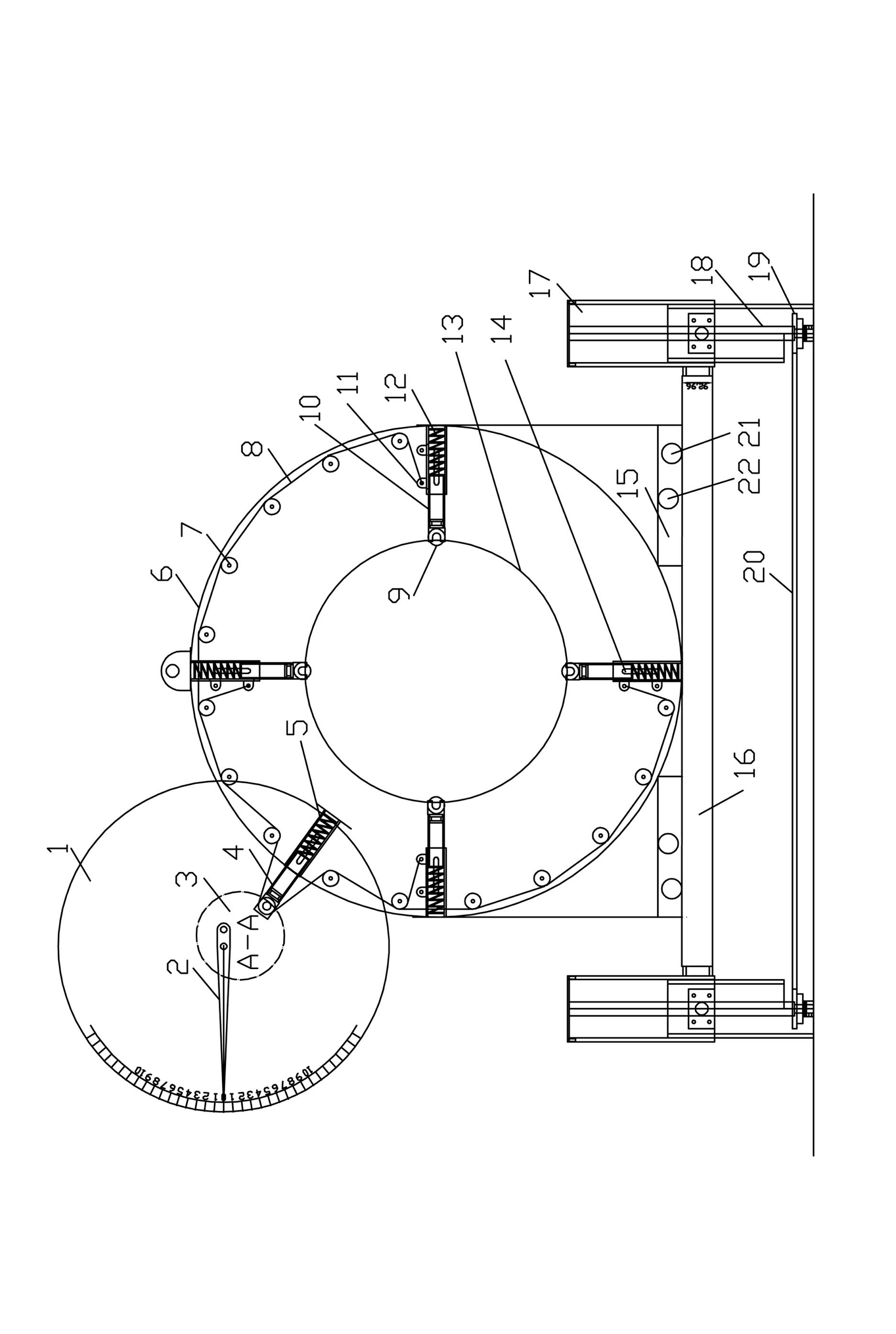

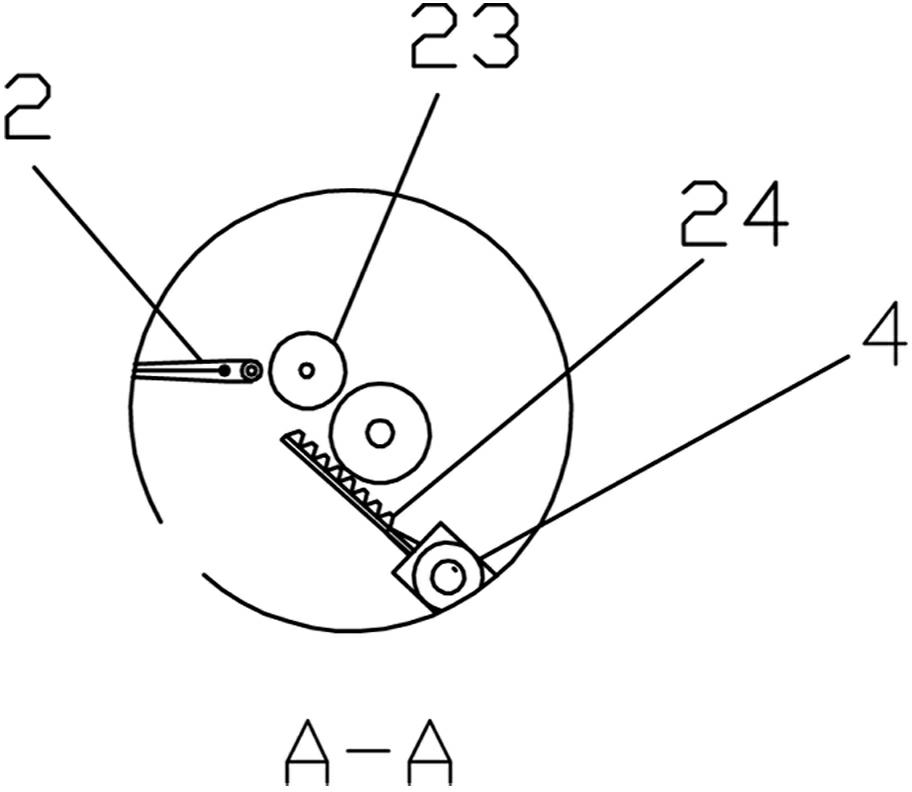

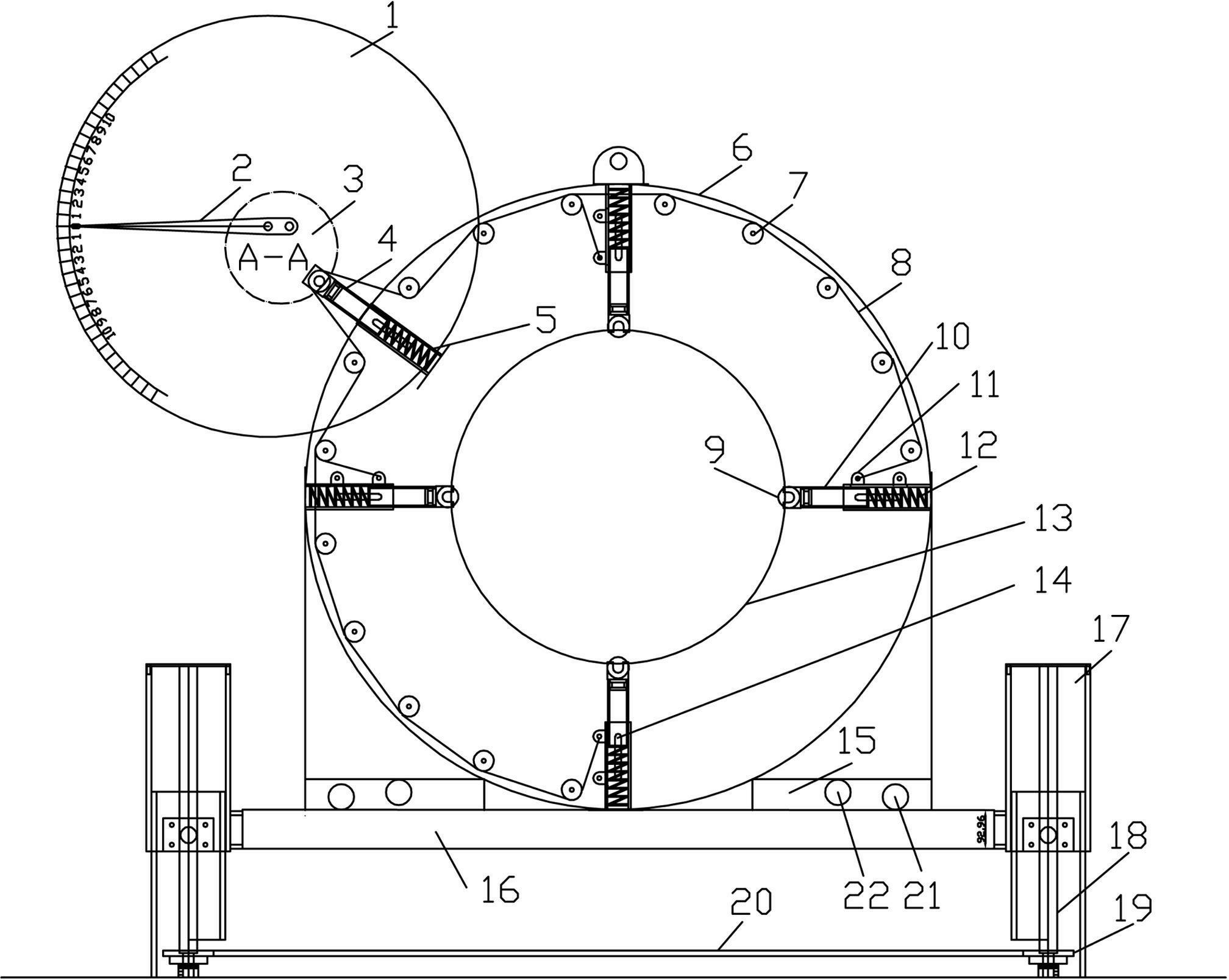

[0012] As shown in the figure: the measuring instrument is supported by two fixed support columns 17, an adjustment screw 18 is arranged inside the support column 17, a drive sprocket 19 and a drive chain 20 are arranged at the bottom of the adjustment screw 18, and a support platform is arranged between the support columns 17 16. The supporting platform 16 is provided with a traveling mechanism 15 capable of left and right adjustment, and a traveling roller 22 and an anti-movement roller 23 are arranged in the traveling mechanism to form an adjustment part;

[0013] The sliding wheel bracket 6 is arranged on the outer side of the steel pipe 13 to be tested, sixteen sets of intermediate wheels 7 are arranged on the inner side of the sliding wheel bracket 6, and four sets of measuring frames 14 are arranged on the sliding wheel bracket 6, and the measuring frames 14 are sequentially arranged on the top from the inside to the outside. Wheel 9, sliding sleeve rod 10 and back press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com