Accelerated life test circuit and test method of power electronic device

A technology for power electronic devices and test circuits, applied in the field of power cycle life test circuits, can solve the problems of high manufacturing cost, inability to accurately detect the time when the gate leads are broken or falling off, and large time errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

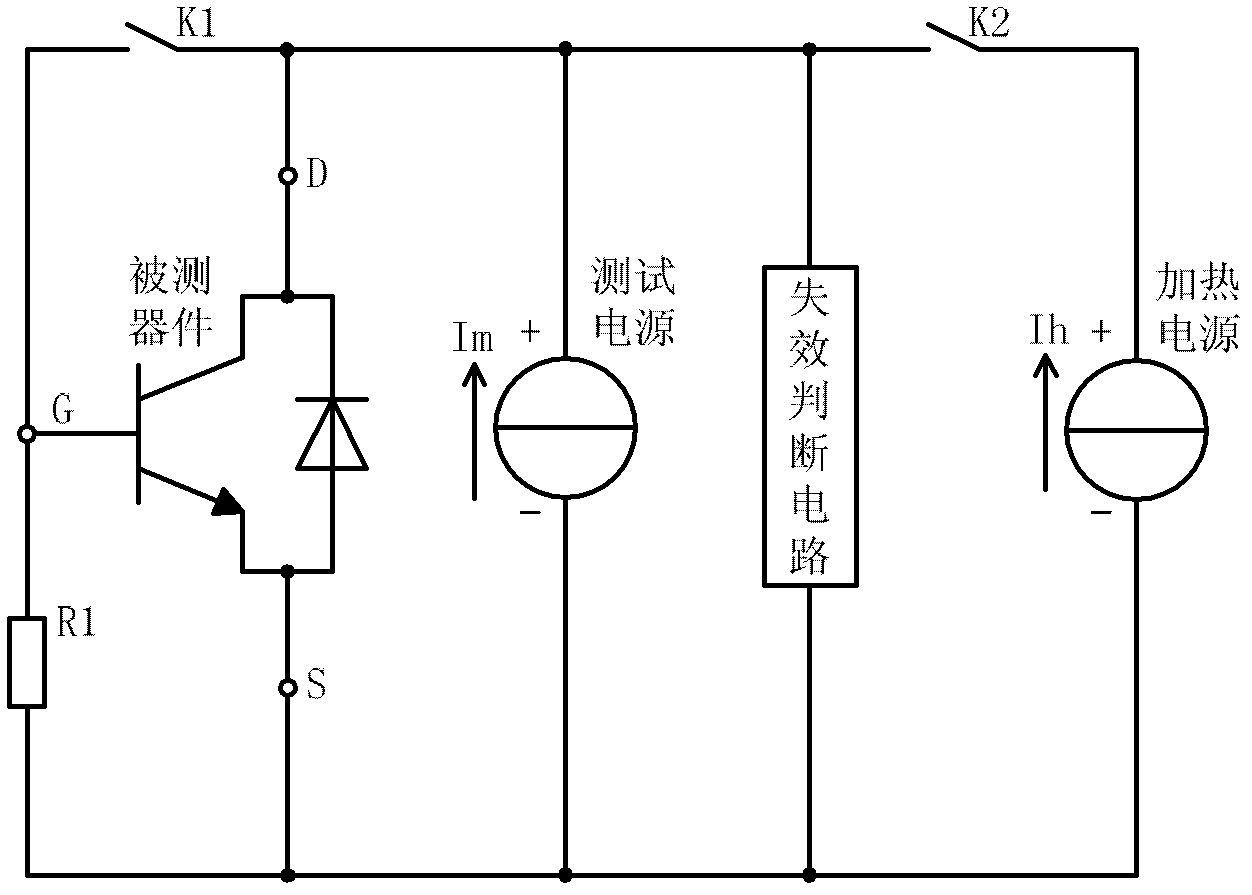

[0026] Such as image 3 As shown, the present invention includes a discharge resistor R1 for gate charge discharge, a first switch K1 for switching the state of the device under test, a second switch K2 for cutting off or enabling the heating current, a constant current test power supply for providing a stable test current, A failure judgment circuit for conduction voltage drop measurement and failure judgment, and a constant current heating power supply for heating current.

[0027] Such as image 3As shown, in the accelerated life test circuit for power electronic devices of the present invention, one end of the first switch K1 is connected to the drain D of the device under test, and the other end of the first switch K1 is connected to the grid G of the device under test; the discharge resistor R1 One end of the discharge resistor R1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com