Anti-Reflection Optical Element and Method for Manufacturing Anti-Reflection Optical Element

An optical element and anti-reflection technology, which is applied in the direction of optical elements, optical elements, chemical instruments and methods, etc., can solve the problems of anti-reflection performance reduction, destruction of micro-concave-convex structures, etc., to suppress reflection and improve resistance to high temperature and high humidity environments , High-temperature and high-humidity environment resistance and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

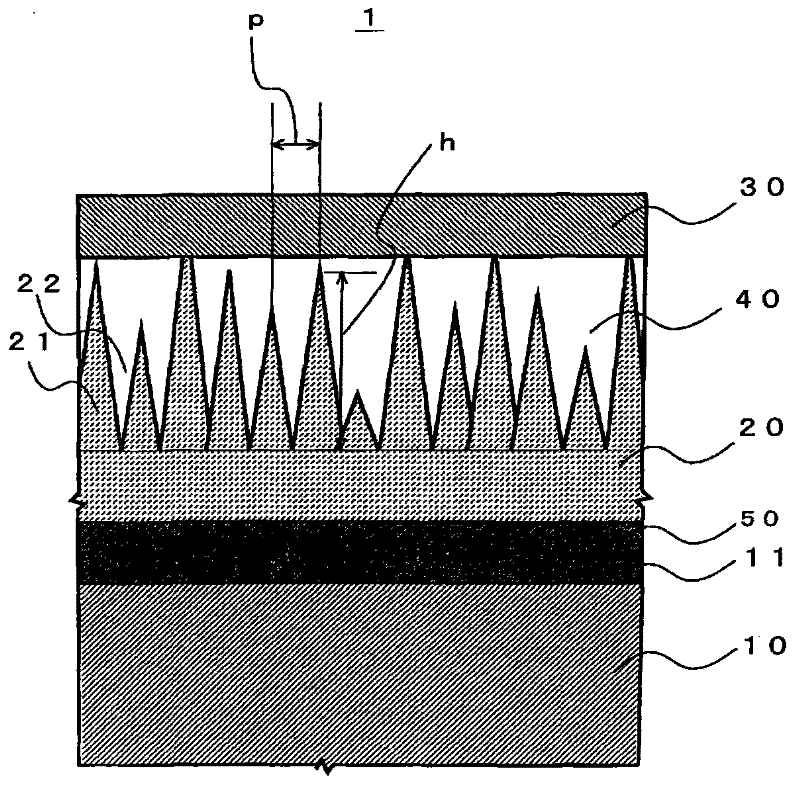

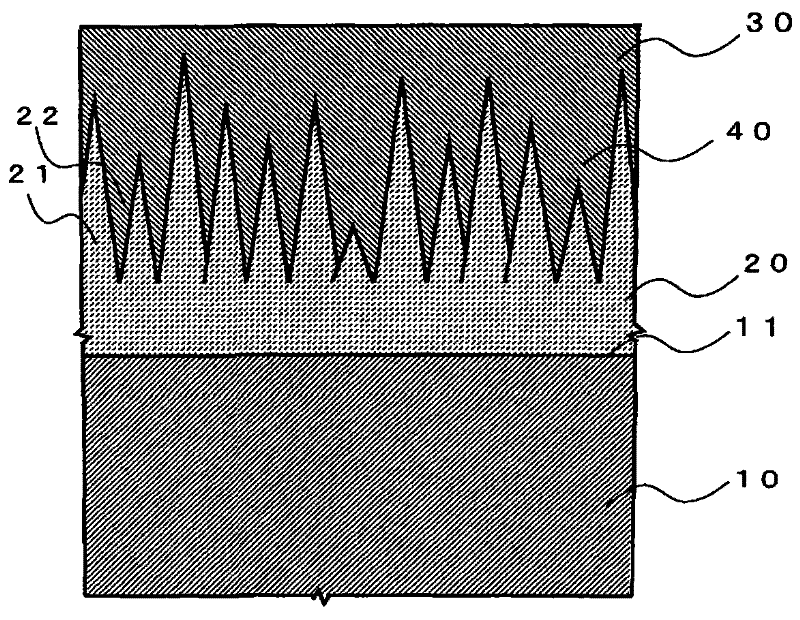

[0101] In Example 1, the optical element main body 10 made of glass is used, and the fine concave-convex structure 20 made of PMMA resin is formed on the optical surface 11 of the optical element main body 10, and it is used as an inorganic light-transmitting material thereafter. SiO 2 , and cover the outside of the fine concave-convex structure 20 with the covering layer 30 . Specifically, the antireflection optical element of Example 1 was manufactured in the following manner.

[0102] First, as the optical element main body 10 , a glass lens made of optical glass (trade name: S-LAH66 (nd=1.77)) manufactured by OHARA Corporation was used. In addition, for the PMMA resin film with a film thickness of 0.2 mm set on the optical surface 11 of this glass lens, use a vacuum evaporation device ARES1510 (Leybold Optics), on the surface of the PMMA resin film, by electron beam evaporation, form 1.25nm TiO measured on a quartz crystal microbalance 2 membrane. At this time, the eva...

Embodiment 2

[0104] In Example 2, a glass lens made of optical glass manufactured by OHARA Corporation (trade name: S-LAH55 (nd=1.83)) was used as the optical element main body 10 . Then, on the optical surface 11 of the optical element main body 10, after forming an optical film 50 composed of four layers (the first layer to the fourth layer) shown in Table 1 in the following order, on the optical film 50, a layer made of PMMA is formed. A fine uneven structure 20 made of resin. Thereafter, as an inorganic light-transmitting material, SiO 2 As a film-forming material, the outside of the fine concave-convex structure 20 was covered with the coating layer 30 in the following procedure. Specifically, the antireflection optical element of Example 2 was produced in the following manner.

[0105] First, on the glass lens made of S-LAH55 as the optical element main body 10, Al 2 o 3 film as the first layer. Then, on the surface of the first layer, ZrO 2 +TiO 2 membrane. In the same way a...

Embodiment 3

[0111] The film thickness of each layer of the optical thin film 50 provided between the optical surface 11 of the optical element main body 10 and the fine concave-convex structure 20 is shown in Table 2. material while using TiO 2 , and the film thickness of the cover layer 30 was set to 5 nm, all the same as the anti-reflection optical element produced in Example 2, and the anti-reflection optical element of Example 3 was produced.

[0112] Table 2

[0113]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com