Color filter and preparation method thereof

A technology of color filters and chromatic elements, which is applied in the fields of optical filters, optics, nonlinear optics, etc., can solve the problems such as the complex preparation process of color filters, achieve simple structure, save the cost of manufacturing materials, and improve manufacturing efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

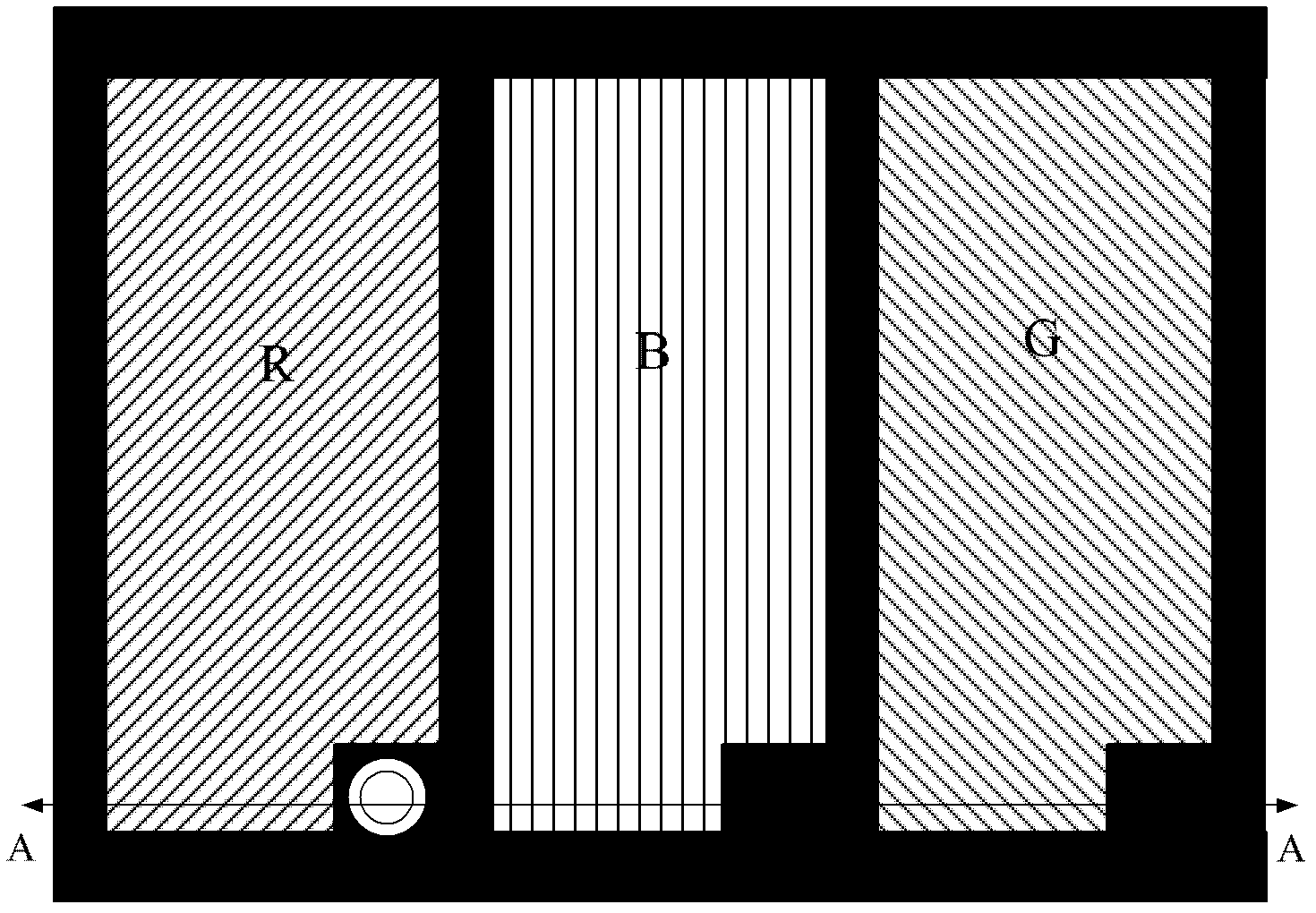

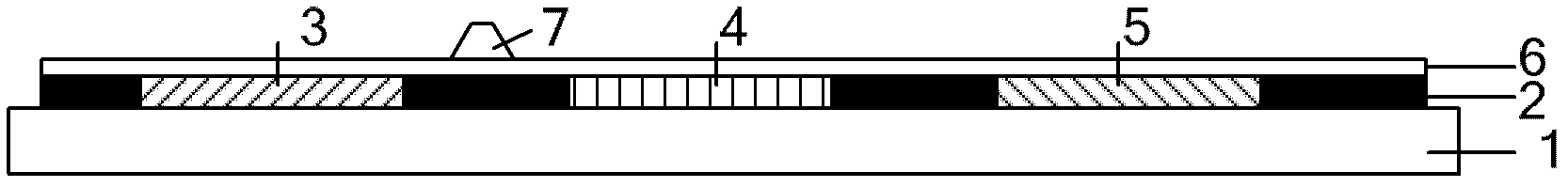

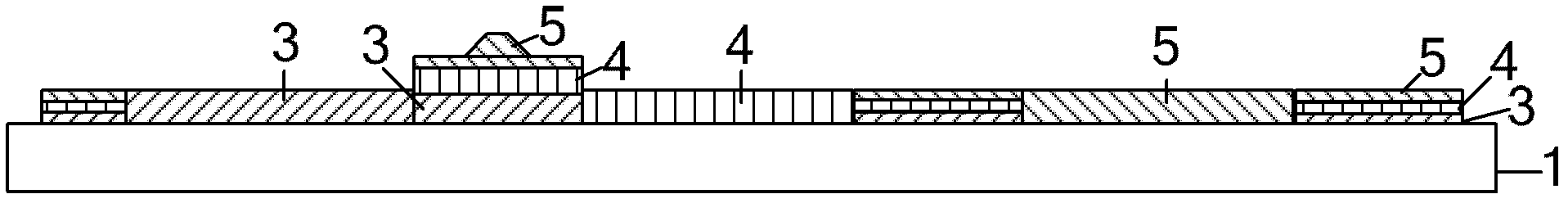

[0033] In Embodiment 1 of the present invention, the hierarchical structure diagram of the color filter is as follows image 3 As shown, the color filter is mainly composed of a glass substrate 1, a red film layer 3, a blue film layer 4 and a green film layer 5; wherein, the black matrix area of the color filter is partially reserved by the red film layer 3, the blue film layer The color film layer 4 and the green film layer 5 are stacked in sequence; the spacer area is formed by sequentially stacking the partially retained red film layer 3, blue film layer 4 and green film layer 5, and is formed by the green film layer 5 on the surface Spacer graphics. Furthermore, by controlling the transmittance when the black matrix area and the spacer area are partially exposed, the color film layer in the partially reserved black matrix area is slightly thinner than the color film layer in the partially reserved spacer area.

Embodiment 2

[0035] Introduce below the preparation method of the color filter with the above-mentioned layered structure of embodiment 1, in the embodiment 2 of the preparation method of the present invention, preferably adopt negative-tone color gel (that is, form insoluble matter after illumination and can obtain the photosensitive material that keeps) Each color film layer is prepared, and its method comprises steps:

[0036] 1. Production of red photoresist film layer:

[0037] Firstly, the glass substrate is cleaned, and then the red photoresist film is coated on the glass substrate, and the glass substrate coated with the red photoresist film is sent to the exposure machine equipment for the exposure process. During the exposure process, red light is used to Mask (mask) design (such as using a half-tone mask or a gray-tone mask), fully expose the red opening area (red sub-pixel area) (make it completely reserved), and partially expose the rest of the area (make it It is partially r...

Embodiment 3

[0044] In embodiment 3 of the present invention, actually covering multiple implementation modes, its difference with embodiment 1, 2 mainly lies in:

[0045] 1. The preparation of the color film layer does not have to be carried out strictly in accordance with the order in Example 2. In fact, the three color film layers of red, green and blue can be prepared in any order, and only need to be processed on the outermost film layer It only needs to produce spacer graphics, which can all achieve the same technical effect.

[0046] 2. It is not necessary to partially expose the three color film layers in the spacer area in strict accordance with the method of Example 2. In essence, as long as a certain protrusion can be formed in the spacer area, (it can be modified by modifying the corresponding Mask pattern implementation).

[0047] 3. The black matrix area does not need to strictly follow the method of Example 1 to form a red, green and blue film layer structure. In essence, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com