Attaching module, apparatus for attaching substrate and method for manufacturing attaching pad

An attachment base and pad technology, applied in the field of manufacturing attachment pads and attachment modules, can solve the problems of polyimide film particle damage, high manufacturing cost, substrate contamination, etc., to achieve improved use efficiency and safety, and improved manufacturing costs. Low, pollution prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, an attachment module of an exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings. In the following exemplary embodiments, for example, an attachment module arranged in a substrate attachment apparatus will be described, but note that the present invention is not limited thereto. Alternatively, the exemplary embodiments of the present invention may be applied to substrate etching equipment, substrate deposition equipment, or other various substrate processing equipment.

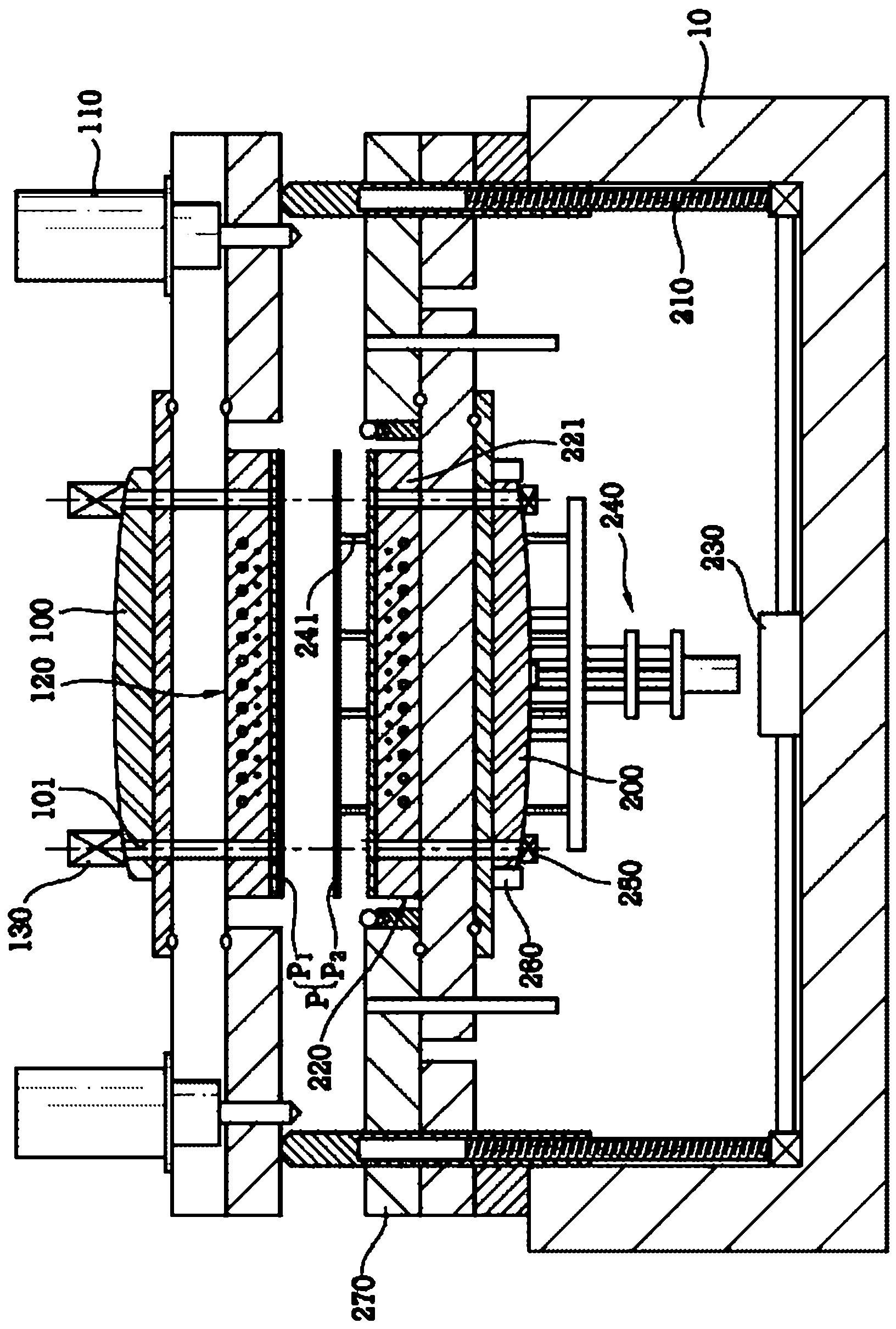

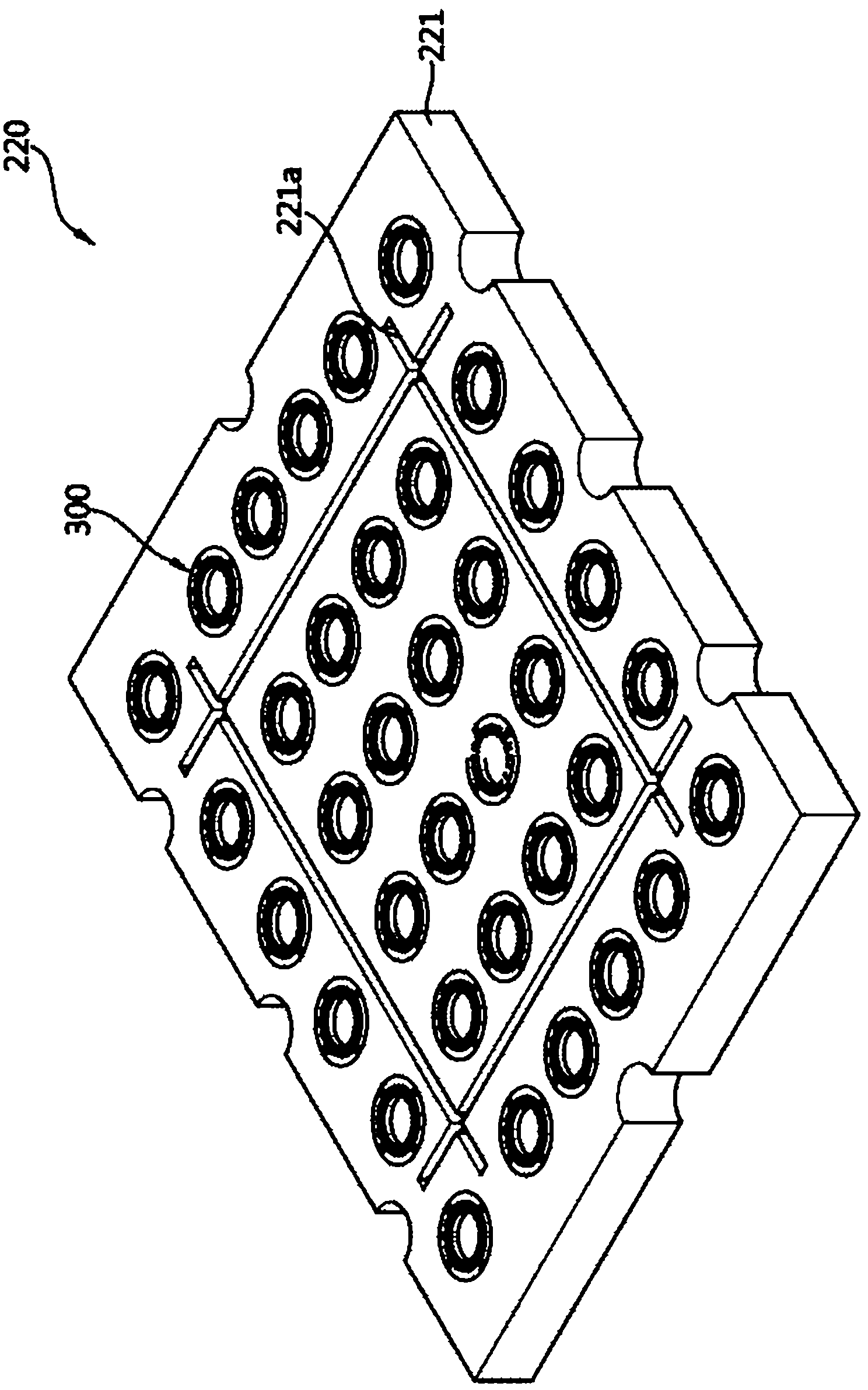

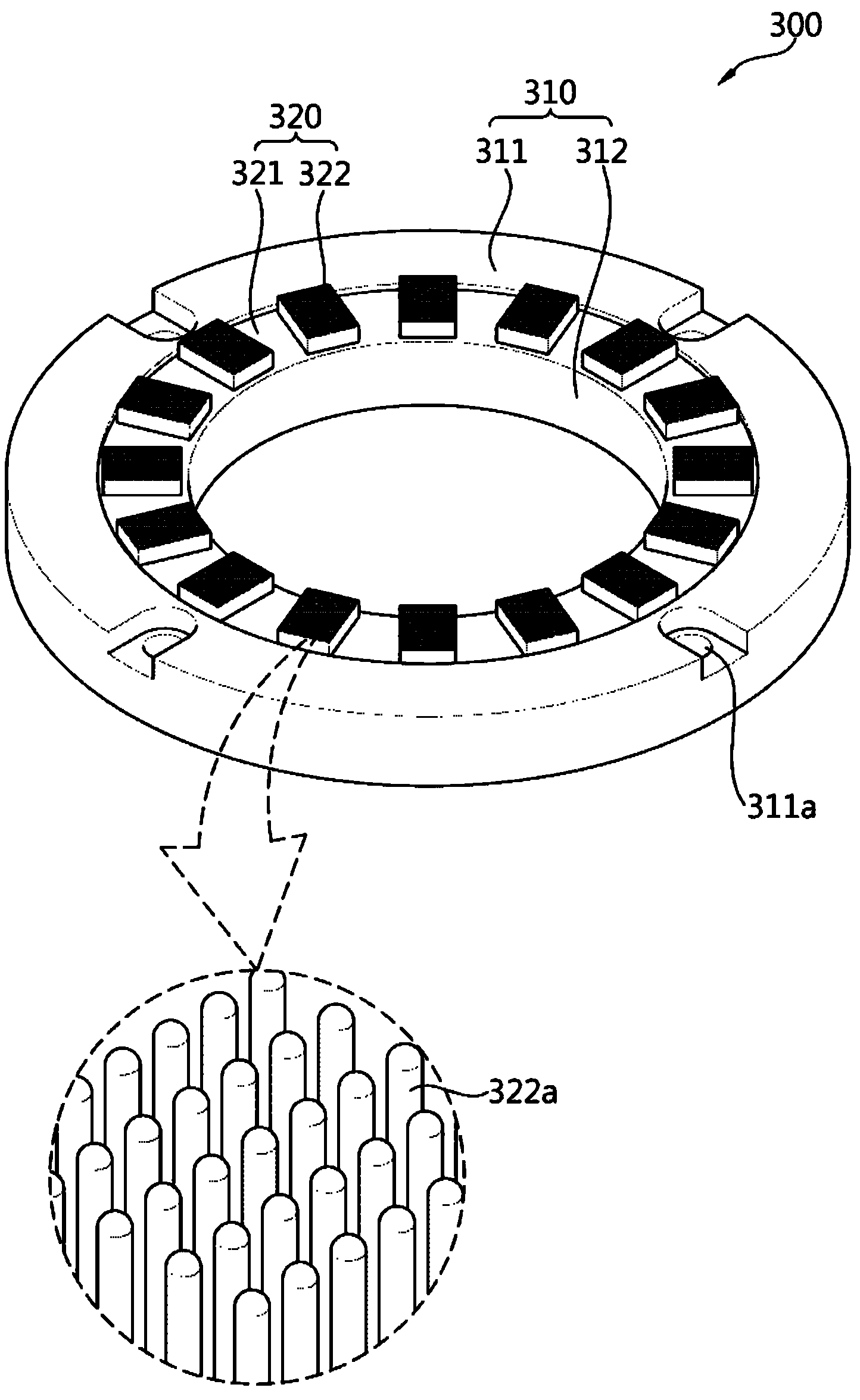

[0026] figure 1 is a sectional view showing a substrate attaching apparatus including the attaching module according to the first exemplary embodiment of the present invention. Such as figure 1 As shown, the substrate attach apparatus includes a base frame 10 forming an exterior appearance. Also, a lower cavity 200 is provided within the base frame 10 , and an upper cavity 100 is provided above the lower cavity 200 . Also, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com