Nucleic acid probe preparation method

A nucleic acid probe and nucleic acid technology, applied in the field of molecular biology, can solve the problem that the molar yield of the liquid-phase amino-activated ester addition method is not high, the liquid-phase amino-activated ester addition method is low in yield, and difficult to synthesize active phosphorous. amide monomer and other problems, to achieve the effect of shortening the reaction time, improving the utilization rate of materials, and improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

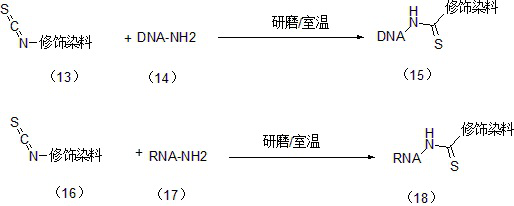

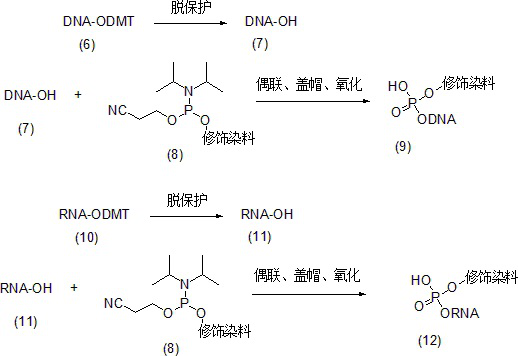

[0042] Example 1 The basic principle of the method of the present invention

[0043] Amorphous flake-like solids of DNA / RNA with amino groups and succinimide-activated ester-modified dyes of crystalline solid-like solids are mixed and ground through solid mixing, which can make the two chemicals fully contact and provide during the grinding process. Sufficient heat; because there is no solvent involved, the reaction has the best concentration effect; at the same time, because the water phase is not used in the reaction, the succinimide activated ester modified dye will not be degraded, and the side reactions are greatly reduced, so that the reaction can be fully carried out.

[0044] The reaction chemical equation of the present invention is as follows:

[0045]

Embodiment approach

[0046] The specific implementation is as follows:

[0047] Step 1, mix 20umol DNA / RNA with amino active group and 60umol succinimide activated ester modified dye solid, perform mechanical grinding at room temperature, fully grind the two solids for 20 minutes, the solid becomes gel during the process shape.

[0048] Step 2, directly dissolving the colloidal substance in 9 ml of ultrapure water, transferring it to a high performance liquid chromatograph, and using 0.1 M triethylamine acetate and acetonitrile for HPLC purification to obtain a pure product.

[0049] The principle of the present invention is:

[0050] (1) Friction generates heat during the grinding process, which makes the Brownian motion of the substance more intense at the molecular level, which helps the reaction to proceed in a positive direction.

[0051] (2) The crystal form of the solid is destroyed during the simultaneous grinding process, and a uniform colloid is gradually formed during the reaction pro...

Embodiment 2

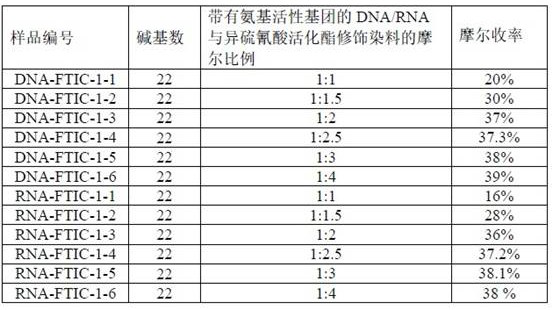

[0052] Example 2. Mixed grinding ratio experiment of DNA / RNA solid with amino active group and succinimide activated ester modified dye solid

[0053] The present invention also screened the relative ratio of the solid-phase amino-activated ester grinding addition method reaction substrate, and the specific embodiments are as follows:

[0054] 1. Get the DNA / RNA solid of 10umol amount and put it into the mortar of 4cm inner diameter;

[0055] 2. Add 10-40umol different amounts of succinimide activated ester modified dye solids in the above-mentioned mortar;

[0056] 3. At room temperature, grind with a mortar rod with a diameter of 1.8 cm for 20 minutes, and the solid forms a viscous gel during the process;

[0057] 4. Add 9ml of ultrapure water in batches on the mortar, dissolve and transfer the above gelatinous substance to a 10ml centrifuge tube;

[0058] 5. The dissolved colloid was directly loaded on the high performance liquid chromatography purifier, and 0.1M triethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com