Method for removing sulfamethazine in water body

A technology of sulfamethazine and water body, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as redox products that have not been seen, and achieve improved catalytic activation ability and use efficiency, The effect of promoting electron transfer and promoting catalytic activation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

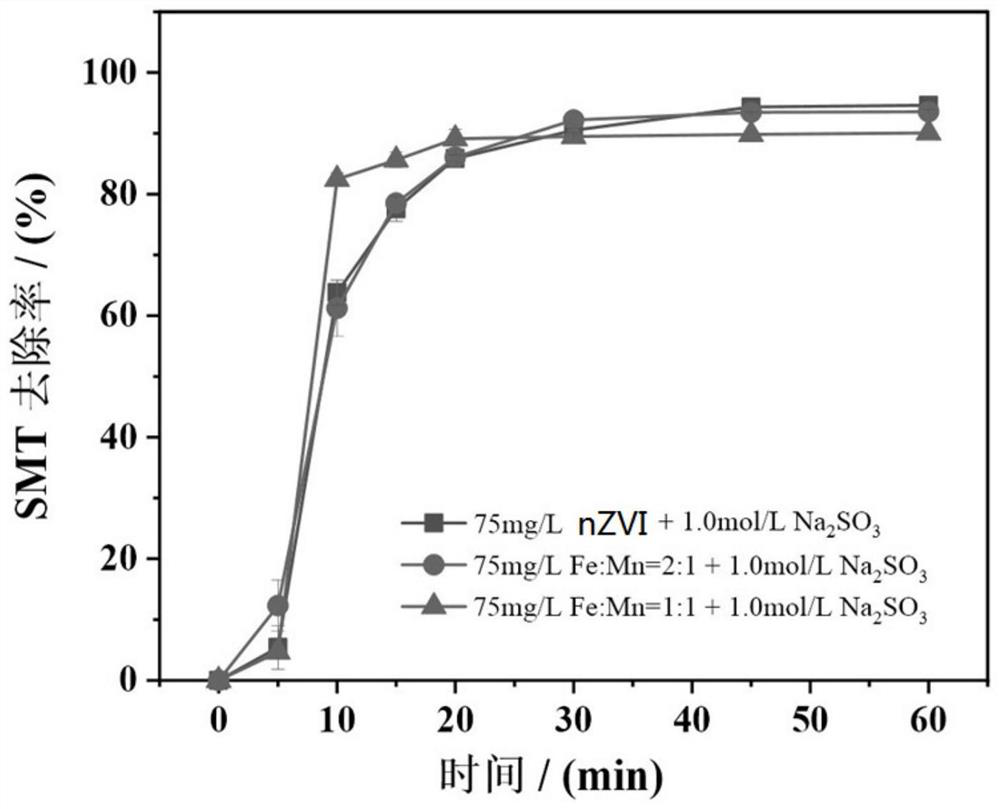

[0033] A method for removing sulfamethazine in water, using nanometer zero-valent iron-manganese material as an activator to activate sulfite to treat sulfamethazine in water, comprising the following steps:

[0034] Add 1mmol of sulfite to every liter of sulfamethazine water according to the amount of sulfite added, and the concentration is 1.0mol / L Na 2 SO 3 The solution is mixed with sulfamethazine water with a pH value of 3.0 and an initial concentration of 5 mg / L. According to the amount of nano-zero-valent iron-manganese material added, 75 mg of nano-zero-valent iron-manganese material is added per liter of sulfamethazine water. , adding nanometer zero-valent iron-manganese materials (Fe:Mn=1:1, Fe:Mn=2:1) and mixing evenly, the obtained reaction system is placed in a digital display water bath constant temperature oscillator for constant temperature oscillation treatment, wherein the constant temperature oscillation treatment The temperature is 25° C., the rotational...

Embodiment 2

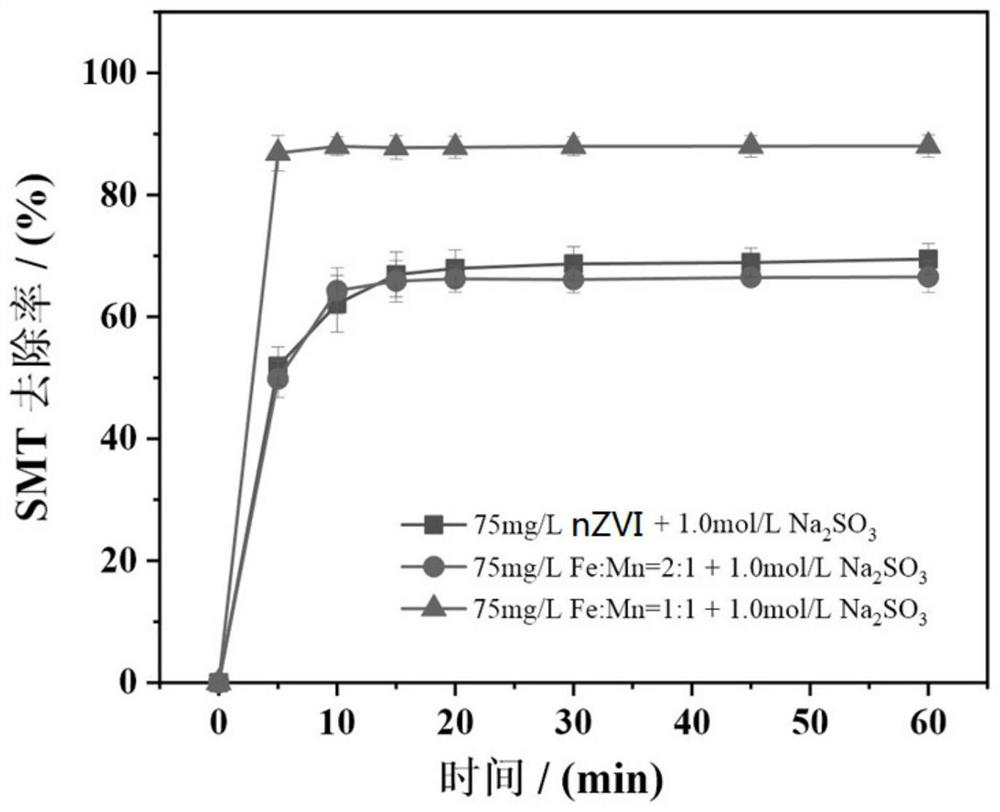

[0047] A method for removing sulfamethazine in water, using nanometer zero-valent iron-manganese material as an activator to activate sulfite to treat sulfamethazine in water, comprising the following steps:

[0048] Add 1mmol of sulfite to every liter of sulfamethazine water according to the amount of sulfite added, and the concentration is 1.0mol / L Na 2 SO 3 The solution is mixed with sulfamethazine water with a pH value of 6.0 and an initial concentration of 5 mg / L. According to the amount of nano-zero-valent iron-manganese material added, 75 mg of nano-zero-valent iron-manganese material is added per liter of sulfamethazine water. , add the nano-zero-valent iron-manganese material (Fe:Mn=1:1, Fe:Mn=2:1) prepared in Example 1 and mix evenly, and the resulting reaction system is placed in a digital display water bath constant temperature oscillator for constant temperature oscillation For the treatment, the temperature of the constant temperature oscillation treatment is ...

Embodiment 3

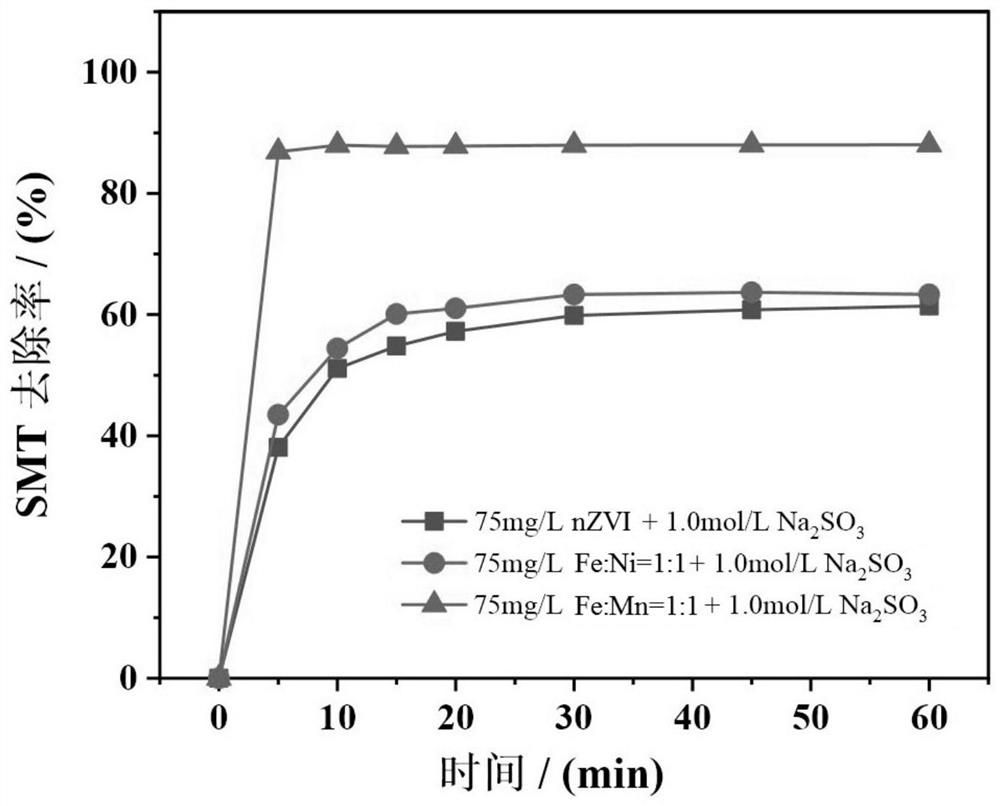

[0057] A method for removing sulfamethazine in water, using nanometer zero-valent iron-manganese material as an activator to activate sulfite to treat sulfamethazine in water, comprising the following steps:

[0058] Add 1mmol of sulfite to every liter of sulfamethazine water according to the amount of sulfite added, and the concentration is 1.0mol / L Na 2 SO 3 The solution is mixed with sulfamethazine water with a pH value of 8.0 and an initial concentration of 5 mg / L. According to the amount of nano-zero-valent iron-manganese material added, 75 mg of nano-zero-valent iron-manganese material is added per liter of sulfamethazine water. , add the nano-zero-valent iron-manganese material (Fe:Mn=1:1, Fe:Mn=2:1) prepared in Example 1 and mix evenly, and the resulting reaction system is placed in a digital display water bath constant temperature oscillator for constant temperature oscillation For the treatment, the temperature of the constant temperature oscillation treatment is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com