High-pressure sterilizing and homogenizing machine for fluid products

A technology for high-pressure sterilization and fluid items, which is applied in the direction of mixers, mixer accessories, dissolution, etc., and can solve the problems of complex piston connecting rods and driving mechanisms, short life, large noise and vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

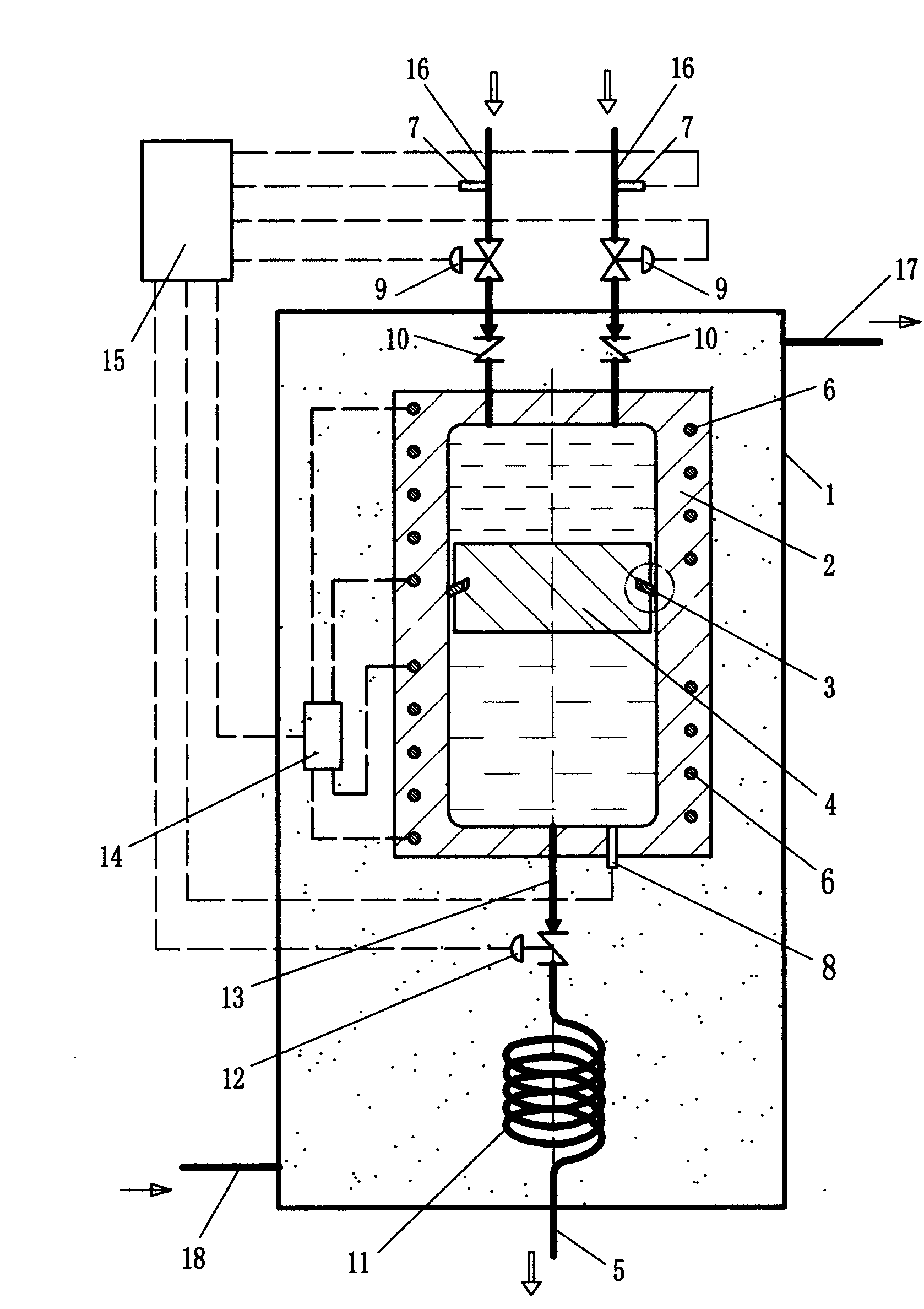

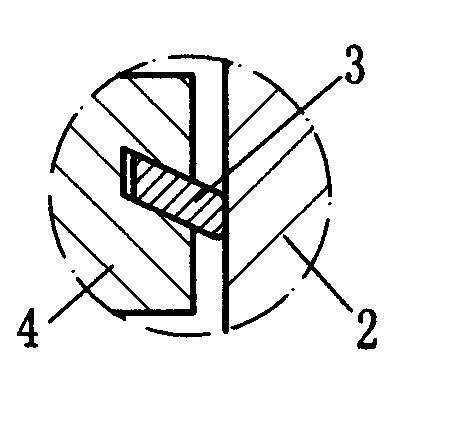

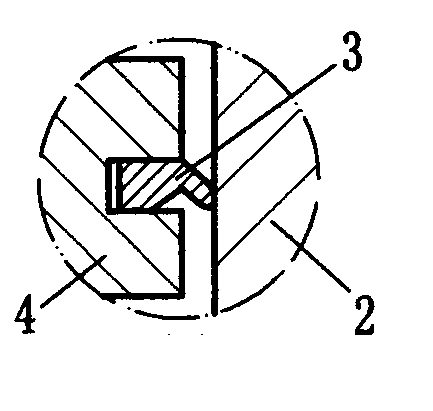

[0024] A sterilizing homogenizer of the present invention is composed of four identical structural units, and the specific implementation of one unit is as attached figure 1 , 2, 3 and 4. The closed casing 1 of the detachable end cover has a piston-type pressurized chamber 2 and an injection chamber 11. The pressurized chamber is closed, and the detachable end cover has a piston 4 inside; There is a gap (0.01mm); there are 2 feed pipes 16, 1 spray pipe 13 and 1 discharge pipe 5, the feed pipe is connected to the part above the piston in the pressurized chamber from the outside of the shell, and one end of the spray pipe is connected to the pressurized The part below the piston in the cavity and the other end are connected to the injection chamber, and the discharge pipe is connected to the injection chamber from the outside of the casing; the feed pipe is connected in series with a pressurized chamber feeding check valve 10, and the injection pipe is connected in series with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com