Fixing method of glass substrate

A glass substrate and attaching technology, applied in the field of flexible display device preparation, can solve problems such as difficulty in handling and processing ultra-thin glass, achieve good barrier effect, improve competitiveness, improve yield and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

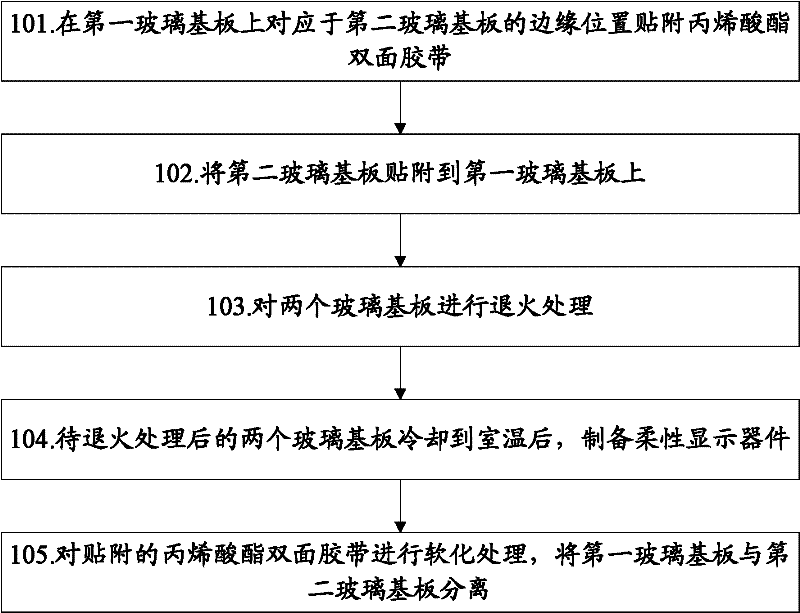

Method used

Image

Examples

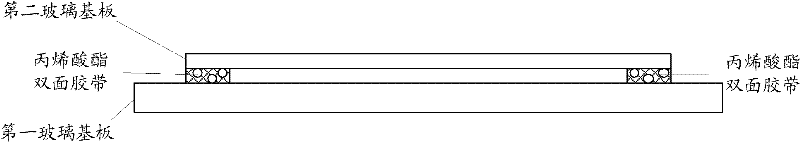

Embodiment Construction

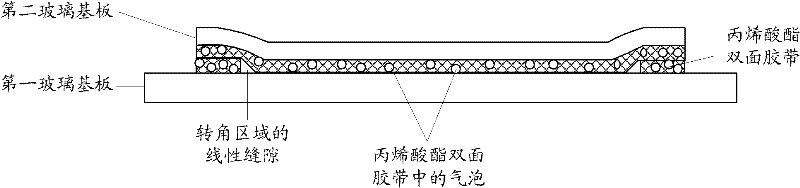

[0030] The manufacturing process of the display device needs to be immersed in organic solvents such as high temperature above 300 ° C, strong acid, strong alkali and isopropanol, so the bonding material that needs to be attached has a certain ability to resist high temperature, strong acid, strong alkali, and organic solvents . Acrylate is one of the materials that can resist high temperature, strong acid, strong alkali, organic solvent and other harsh environments for a certain period of time, and can provide high bonding strength. However, the double-sided tape prepared by acrylate contains a lot of air bubbles , if it is directly used to bond two glass substrates, it is easy for the liquid to infiltrate between the glass substrates through air bubbles during the preparation of the display device, resulting in unevenness in the middle of the ultra-thin glass substrate in a high temperature or vacuum environment, affecting product performance , or even serious damage to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com