Antistatic coating

An antistatic and antistatic agent technology, applied in the direction of conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor weather resistance and performance degradation, and achieve excellent antistatic performance, excellent performance, and excellent antistatic performance Effect

Inactive Publication Date: 2012-09-26

TIANCHANG JULONG TRAVEL PAINT

View PDF5 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing high-temperature-resistant and anti-static coatings, while ensuring anti-static and high-temperature resistance, will lead to the reduction of other properties, such as poor weather resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

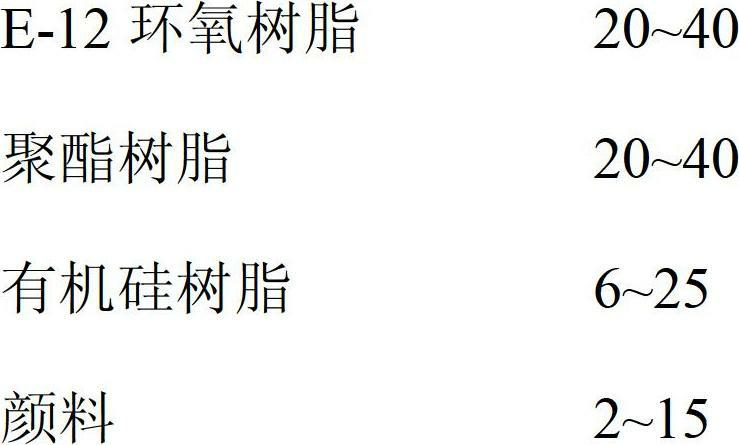

[0039] Described coating comprises by weight parts:

[0040]

[0041]

Embodiment 2

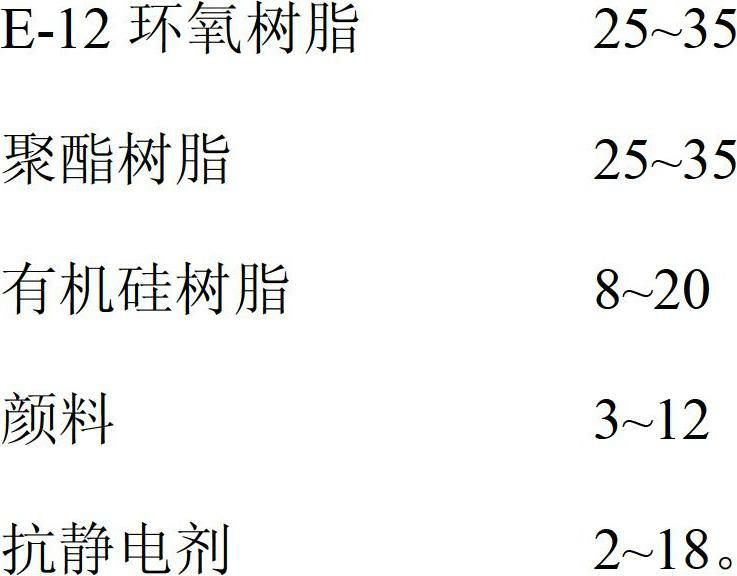

[0043] Described coating comprises by weight parts:

[0044]

Embodiment 3

[0046] Described coating comprises by weight parts:

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an antistatic coating, which is characterized in that the coating comprises the following components in parts by weight: 20-40 parts of E-12 epoxy resins, 20-40 parts of polyester resins, 6-25 parts of organic silicon resins, 2-15 parts of pigments and 1-20 parts of antistatic agents. With the adoption of the antistatic coating, the antistatic property of the coating can be guaranteed, and meanwhile, the coating has excellent performances of adhesion, weather resistance, abrasion resistance, high-temperature resistance and the like.

Description

technical field [0001] The present invention relates to a paint, in particular, the present invention relates to an antistatic paint. Background technique [0002] Antistatic coatings are functional coatings that have the ability to conduct electricity and dispel accumulated static charges. Antistatic coatings have been developed along with modern science and technology, and have a history of more than half a century. As early as 1948, the United States published a patent for making conductive adhesive from silver and epoxy resin, which was the earliest disclosed conductive paint. In the 1950s, Japan began to produce anti-static coatings mainly based on silver and carbon. In the 1960s, the United States, Britain, Japan and other countries successively developed antistatic coatings. In the 1980s, foreign antistatic technology and electrothermal coating technology developed rapidly, and my country also began to study and apply antistatic coatings in the 1950s. [0003] Gen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/00C09D167/00C09D167/02C09D183/00C09D183/10C09D183/12C09D183/04C09D7/12C09D5/24

Inventor 孙保国

Owner TIANCHANG JULONG TRAVEL PAINT

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com