Foaming-type flushing closestool

A foaming and flushing technology, which is applied to water supply devices, flushing equipment with water tanks, sanitary equipment for toilets, etc., can solve the problems of incomplete flushing, rapid recovery of water seal blocks, and unsatisfactory foaming effects and other problems, to achieve the effect of simple structure, space saving and easy coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

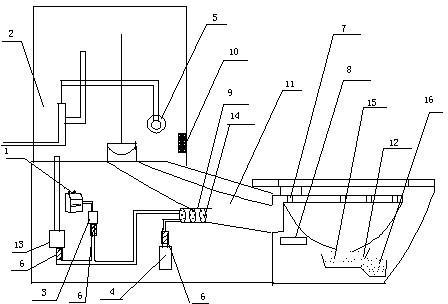

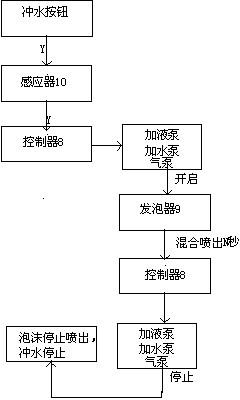

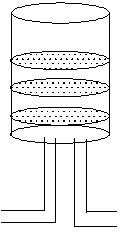

[0020] Such as figure 1 As shown, the present embodiment provides a foaming flush toilet, including a water tank 2, a controller 8, a through hole 7, and a drain pipe 11, and it is characterized in that: the water tank base of the toilet is provided with a raw liquid tank 1, a Liquid pump 3, air pump 4, foamer 9, described raw liquid tank 1 links to each other with filling pump 3 through pipeline, adds liquid pump 3, air pump 4, water tank 2 is connected with bubbler 9 through pipeline respectively, wherein water tank 2 The pipeline communicating with the foamer 9 is provided with a water pump 13, the foam pipe of the foamer 9 communicates with the drain pipe 11 at the bottom of the water tank 2, and the side wall of the water tank is equipped with an inductor 10 and a controller 8 After receiving the signal from the sensor 10, the liquid fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com