Kara OK-V shaped connecting plate and truss consisting of same

A technology of OK-V and connection plate, which is applied in the field of trusses, can solve the problems of construction and section weakening, large amount of screws, labor and time-consuming, etc., and achieve the effect of improving assembly efficiency and facilitating semi-mechanized and fully mechanized assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

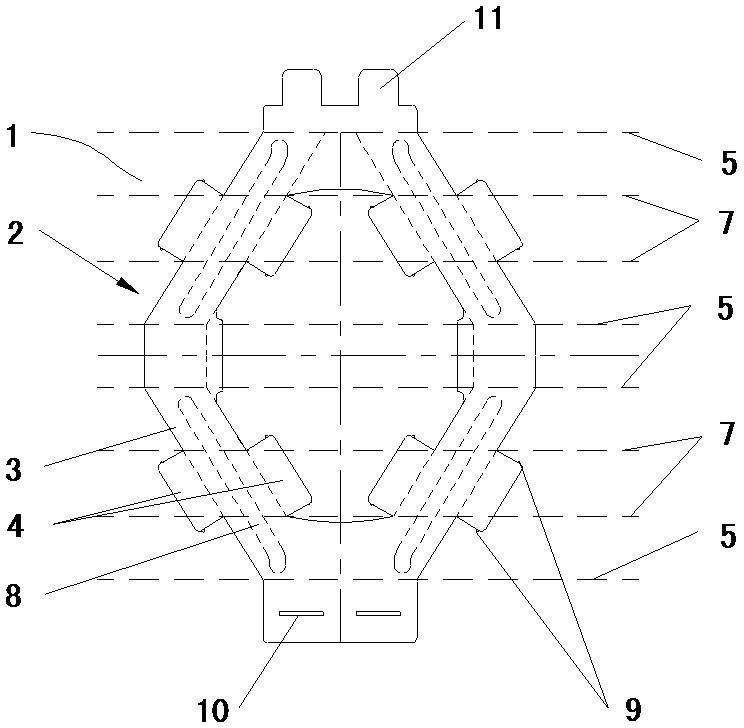

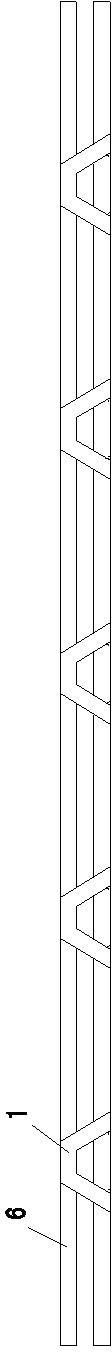

[0027] Such as figure 1 Shown is a schematic structural view of the first embodiment of the karaoke-V-shaped connecting plate of the present invention. The karaoke-V-shaped connecting plate of this embodiment includes a connecting plate body 1, and the connecting plate body 1 includes at least one connecting unit 2 in a rhombus or square shape, and the connecting unit 2 includes four connecting sides 3, and the middle part of each connecting side 3 Both are provided with a web 4 , the connecting plate body 1 can be folded along a preset folding line and then connected into a closed structure, and the two sides of the web 4 are perpendicular to the corresponding connecting edge 3 .

[0028] Such as figure 1 As shown, there is one connecting unit 2 in this embodiment, and the connecting body 1 can be folded along four folding lines I 5 parallel to the diagonal of the connecting unit 2 to form a closed structure. The distance L between the vertical feet between the two sides of...

no. 2 example

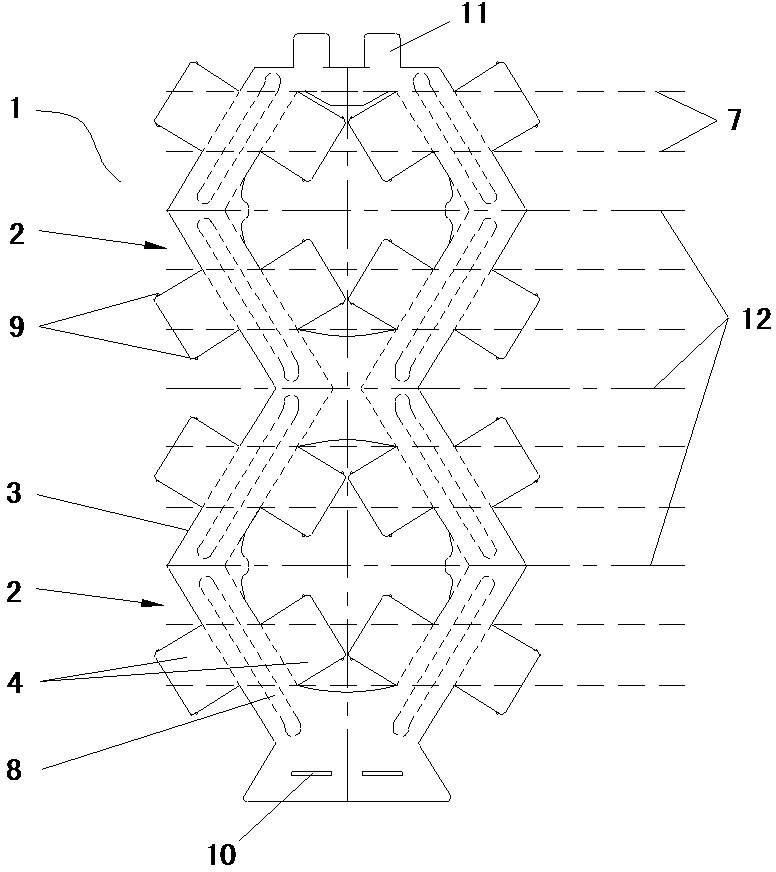

[0037] Such as image 3Shown is a schematic structural view of the first embodiment of the karaoke-V-shaped connecting plate of the present invention. The karaoke-V-shaped connecting plate of this embodiment includes a connecting plate body 1, and the connecting plate body 1 includes at least one connecting unit 2 in a rhombus or square shape, and the connecting unit 2 includes four connecting sides 3, and the middle part of each connecting side 3 Both are provided with a web 4 , the connecting plate body 1 can be folded along a preset folding line and then connected into a closed structure, and the two sides of the web 4 are perpendicular to the corresponding connecting edge 3 .

[0038] Such as image 3 As shown, there are two connecting units 2 in this embodiment, and the connector body 1 can be folded along three folding lines II 12 and then connected to form a closed structure. The three folding lines II 12 are respectively the diagonal lines and The connecting line bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com