Electrically-controlled fuel injector for large diesel engines

A technology for diesel engines and fuel injectors, which is applied to fuel injection devices, special fuel injection devices, engine components, etc., to achieve the effect of minimizing required emissions and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

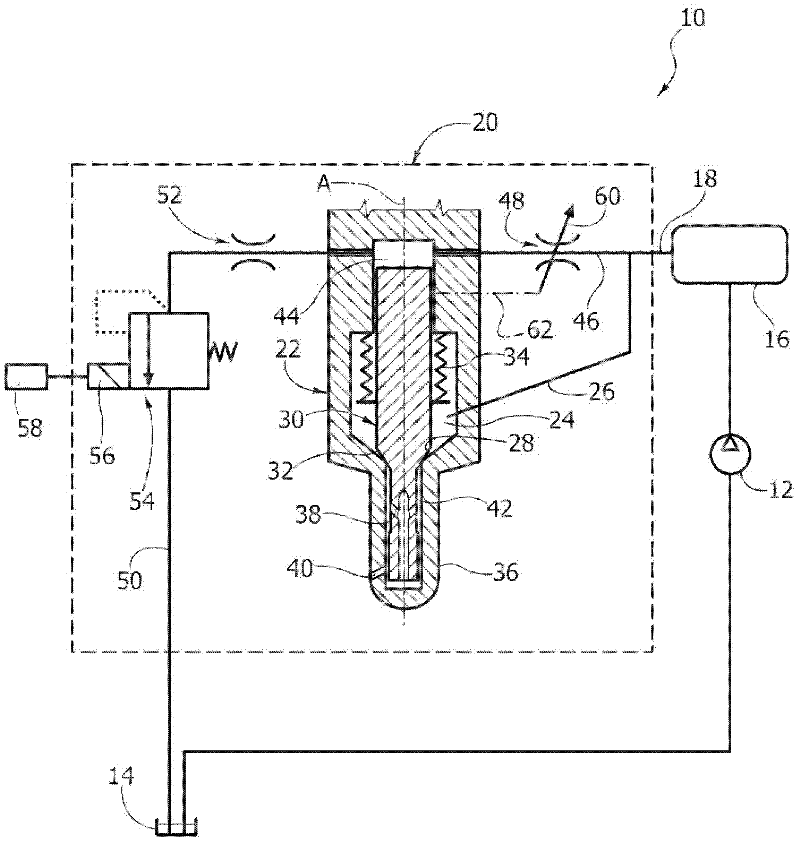

[0028] see figure 1 , an injection system for a diesel engine is indicated by reference numeral 10 . The injection system includes a charge pump 12 that draws fuel from a low pressure fuel storage tank 14 and delivers the pressurized fuel to a high pressure common rail 16 . The common rail 16 is connected to a plurality of high-pressure pipelines 18 (in figure 1 Only one is shown in ), each delivery high pressure line is connected to a respective injector 20.

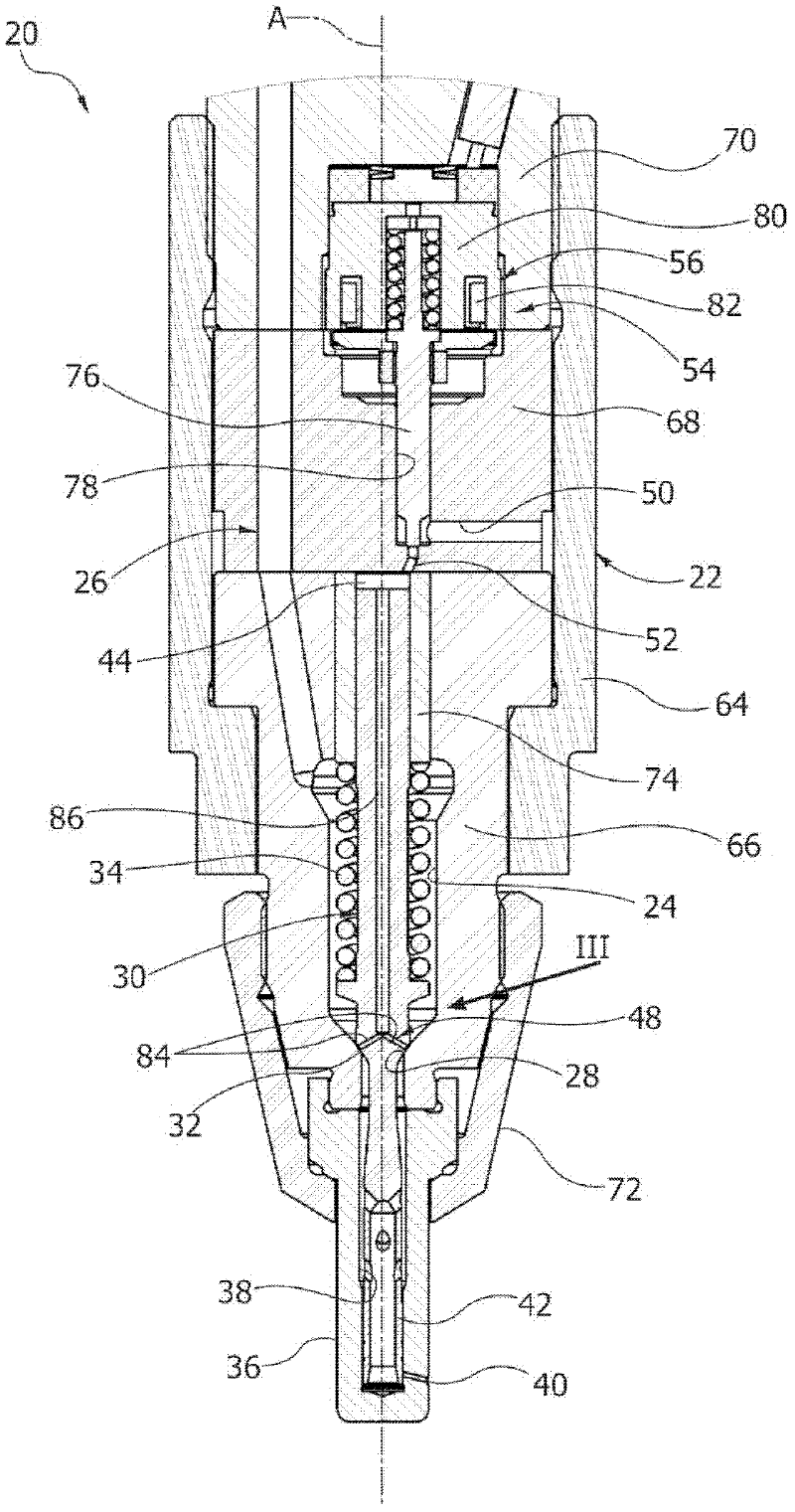

[0029] Injector 20 includes a body 22 having a delivery chamber 24 connected to high pressure line 18 by a fuel supply line 26 . The delivery chamber 24 has a conical valve seat 28 .

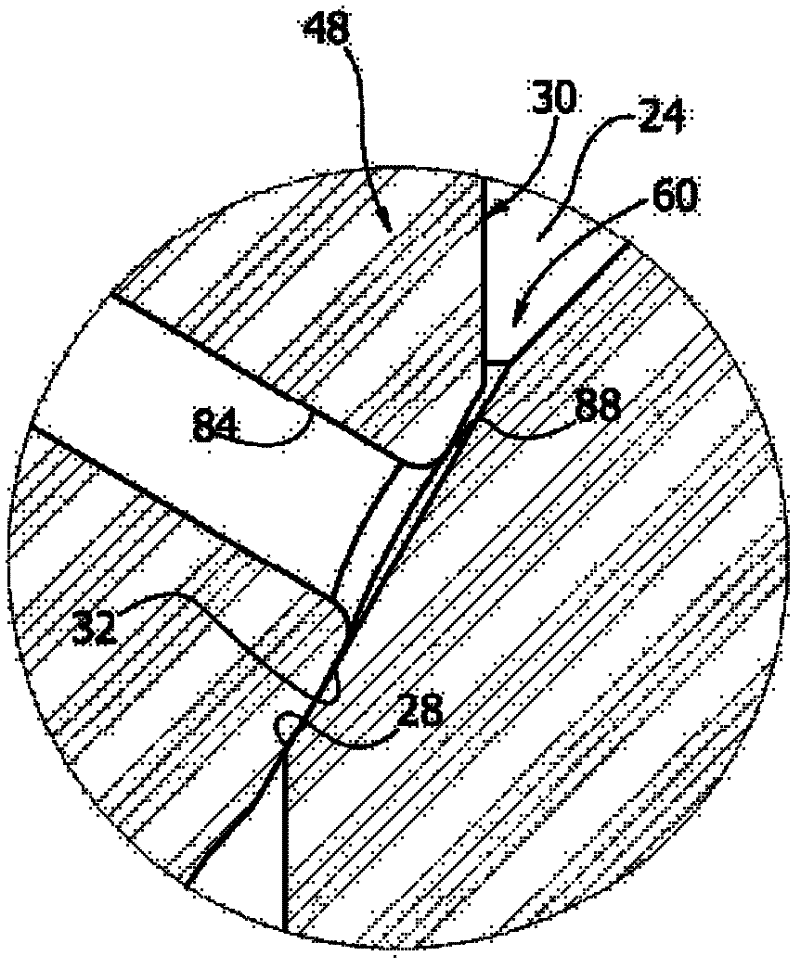

[0030] The injector 20 includes a valve needle 30 that extends through the delivery chamber 24 and has a conical sealing surface 32 that cooperates with the valve seat 28 . Valve needle 30 is movable along longitudinal axis A between a closed position and an open position. In the closed position, the sealing surface 32 abuts the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com