Heat conductive plastic heat exchange module used for countercurrent closed cooling tower

A closed cooling tower, thermally conductive plastic technology, applied in direct contact heat exchangers, water shower coolers, heat exchanger types, etc. The effect of preventing intermediate sag, expanding the scope of application, and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

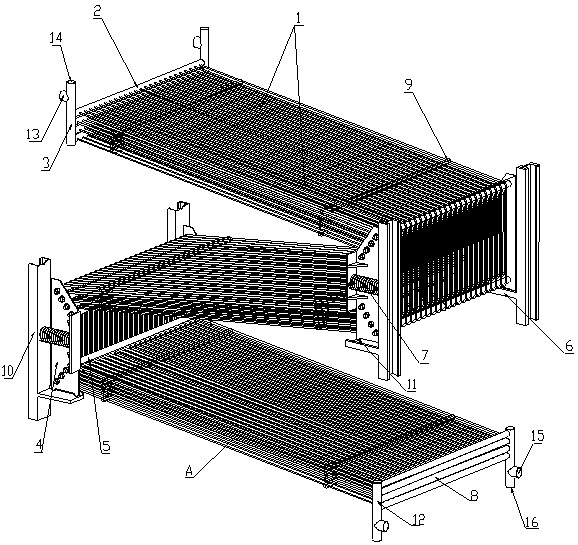

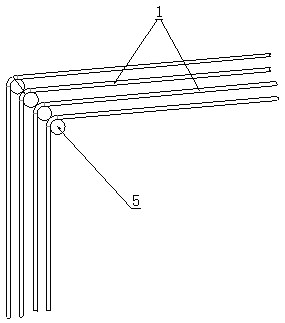

[0021] as attached figure 1 As shown, the heat-conducting plastic heat exchange module for the counter-flow closed cooling tower of the present invention includes a heat-conducting plastic thin tube 1, a water inlet header 3, an outlet pipe 12, upper and lower headers 2, 8, and partition strips 9 , Module frame 10, fixed plate 4, support rod 5, support plate 6, tensioning device, etc. The diameter of the heat-conducting thin plastic tube 1 is φ≤10mm.

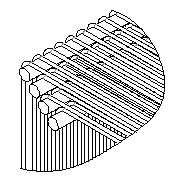

[0022] The upper and lower headers 2, 8 are respectively fixed to the module frame 10. The two ends of a plurality of heat-conducting thin plastic tubes 1 are thermally melted on the upper and lower headers 2 and 8 respectively to form a layer of heat-conducting thin plastic tube grids. There are partition strips 9 between the heat-conducting thin plastic tubes 1 to maintain the distance between the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com