Water and air dual-purpose pressure testing machine

A pressure test, dual-purpose technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of working environment pollution, time-consuming and labor-intensive operators, and the inability of the pneumatic testing machine to accurately determine the abnormal position, etc., to achieve operation Simple and convenient, accurate abnormal judgment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

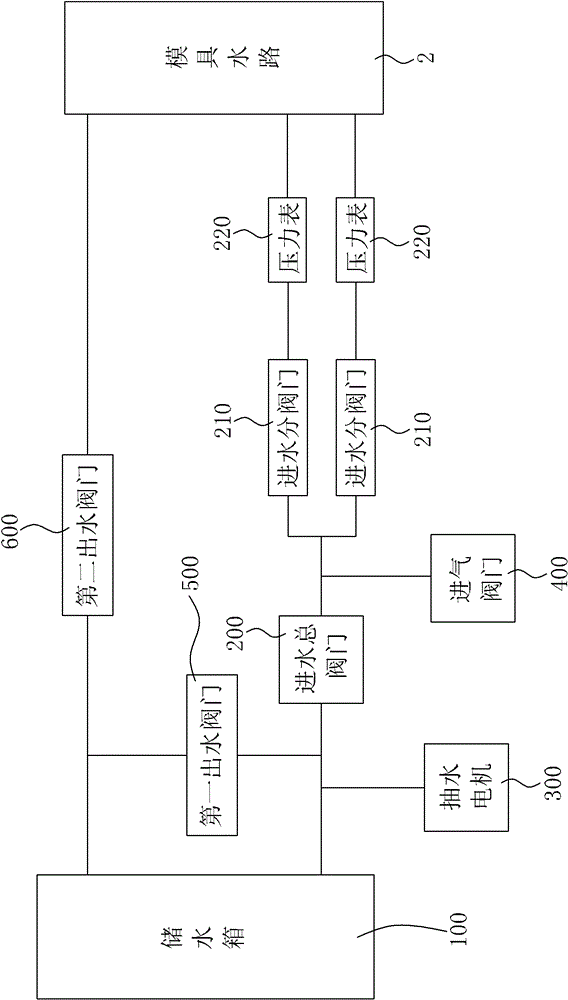

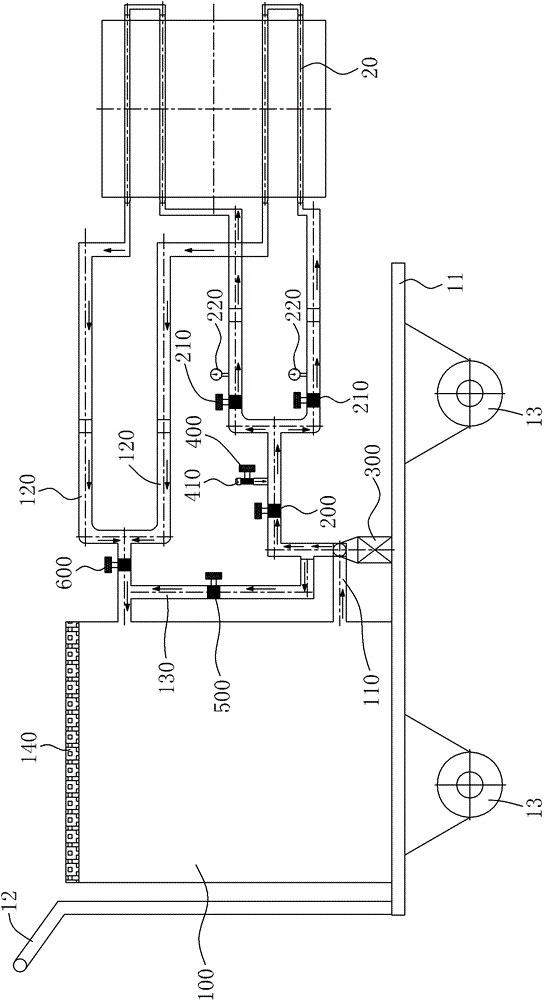

[0017] see figure 1 , figure 2 As shown in FIG. 2 , they respectively show a structural block diagram of the water-air dual-purpose pressure testing machine of the present invention, and a structural schematic diagram of the water-air dual-purpose pressure testing machine of the present invention.

[0018] The water-air dual-purpose pressure testing machine of the present invention is used to test the pressure of the mold waterway, and the water-air dual-purpose pressure testing machine includes:

[0019] A water storage tank 100, the water storage tank 100 is provided with a water inlet pipe 110 and a water outlet pipe 120, the water inlet pipe 110 and the water outlet pipe 120 are connected to the mold waterway 20 respectively, and a pressure relief pipe is provided between the water inlet pipe 110 and the water outlet pipe 120 130, and the water storage tank 100 is provided with a water cover 140;

[0020] The main water inlet valve 200 is arranged on the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com