Silicon-carbon composite material, preparation method thereof and lithium ion battery employing same

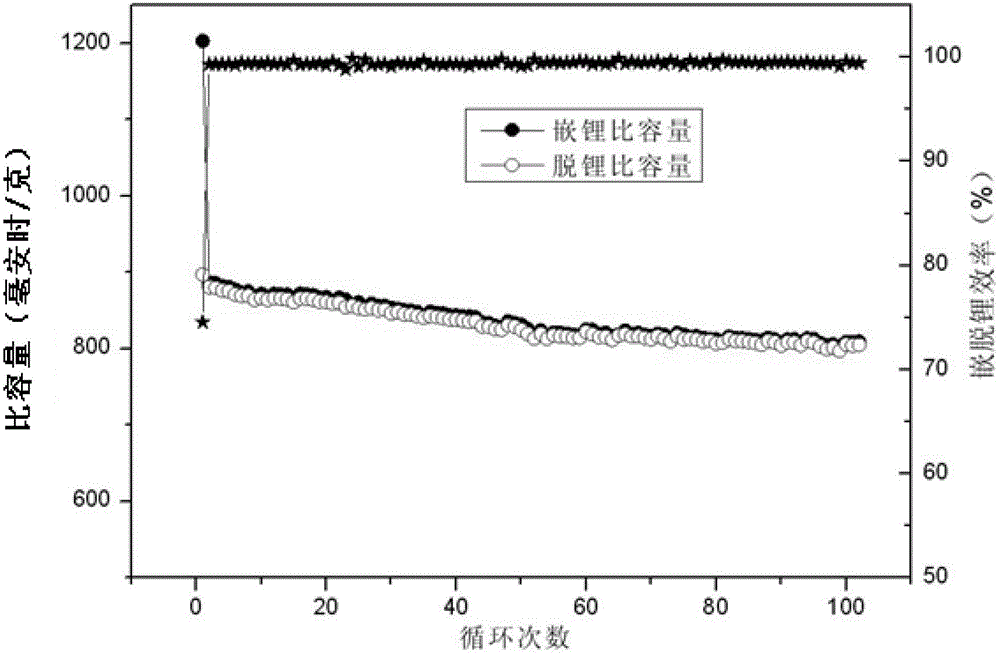

A silicon-carbon composite material, composite material technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve problems such as slow decay, increase stability and electrical conductivity, easy to implement , the effect of improving specific capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

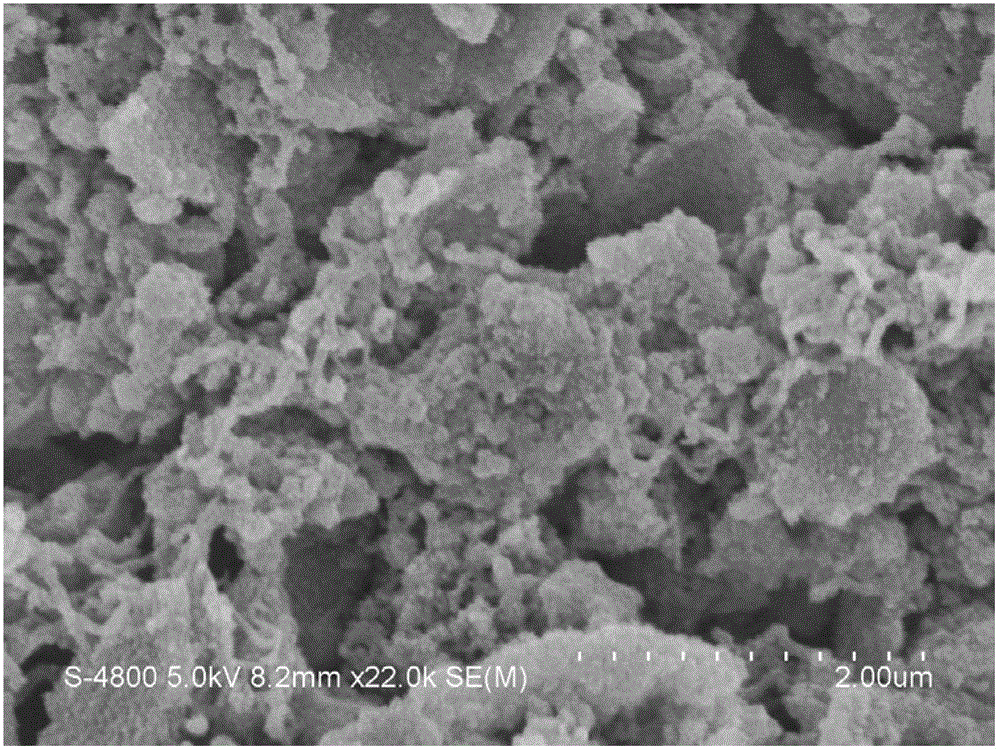

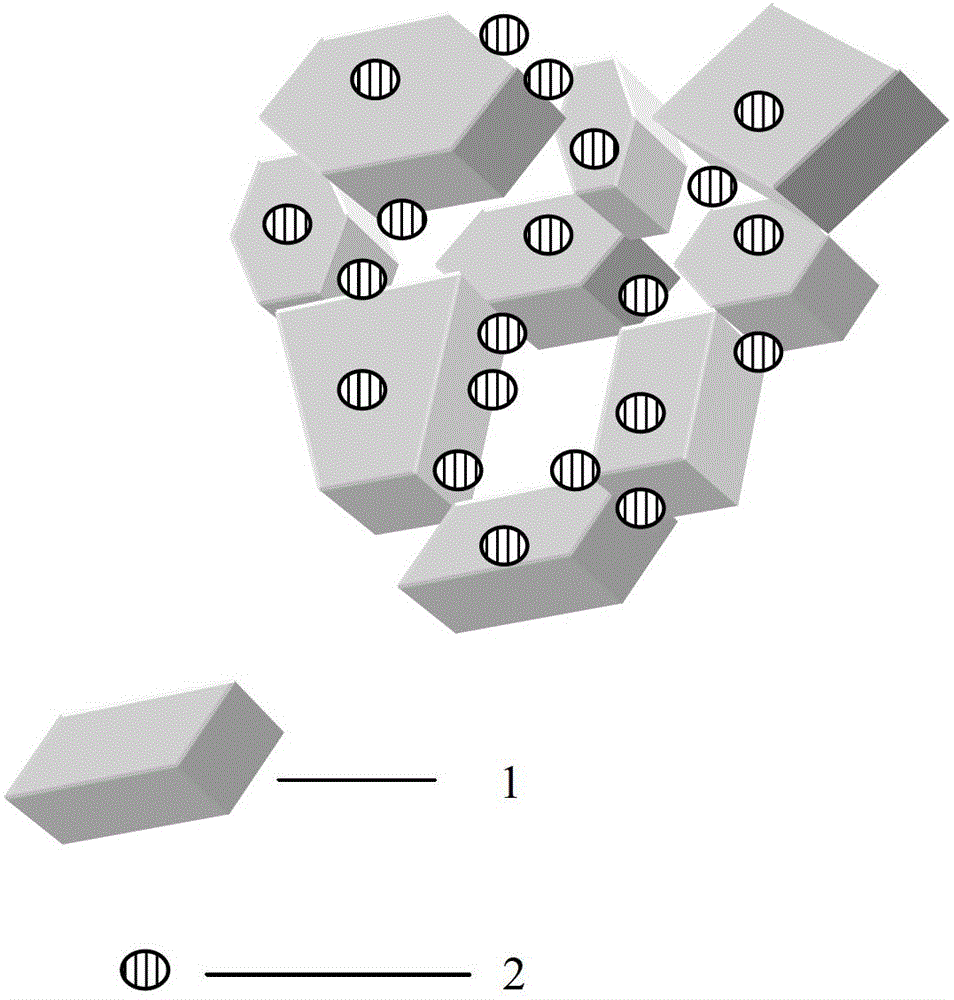

[0038] (1) Put silicon monoxide into a porcelain boat, raise the temperature to 1050°C under the protection of nitrogen, keep the temperature at this temperature for 24 hours, make disproportionation reaction of silicon monoxide at high temperature, and cool to room temperature to obtain a brown product. The tan product includes a composite material of silica-coated nano-silicon particles and partially incompletely reacted silicon monoxide, wherein the nano-silicon particles are uniformly dispersed in the silica matrix. Mix the resulting tan product, expanded graphite (50% of the mass of the tan product), and a hydrofluoric acid solution with a concentration of 13 wt%, wherein the molar ratio of hydrofluoric acid to silicon monoxide initially added is 6:1 , after stirring for 10 hours, ultrasonically dispersed for 120 minutes, wherein, the nano-silicon ...

Embodiment 2

[0045] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0046] (1) Put silicon monoxide into a porcelain boat, raise the temperature to 1200°C under the protection of nitrogen, keep the temperature at this temperature for 0.5h, make disproportionation reaction of silicon monoxide at high temperature, and cool to room temperature to obtain a brown product. Mix the obtained tan product with a hydrofluoric acid solution with a concentration of 20wt%, wherein the molar ratio of hydrofluoric acid to silicon monoxide added initially is 4:1, and after stirring for a period of time, add three times the mass of silicon monoxide Graphite, stirred for 30 hours, ultrasonically dispersed for 5 minutes, filtered to obtain a solid product after ultrasonic dispersion, washed with distilled water to remove hydrofluoric acid, fluosilicic acid, etc. A composite material of nano-silicon particles, wherein the particle size of n...

Embodiment 3

[0052] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0053] (1) Put silicon monoxide into a porcelain boat, raise the temperature to 800°C under the protection of nitrogen, keep the temperature at this temperature for 6 hours, make disproportionation reaction of silicon monoxide at high temperature, and cool to room temperature to obtain a brown product. The resulting tan product was mixed with carbon nanotubes (the mass of which was 10% of the brown product), and then a hydrofluoric acid solution with a concentration of 3 wt% was added, wherein the molar ratio of hydrofluoric acid to the initially added silicon monoxide was 10 : 1, after stirring for 0.5 hours, ultrasonically disperse for 80 minutes, filter to obtain a solid product after ultrasonic dispersion is completed, wash with distilled water to remove hydrofluoric acid, fluorosilicic acid, etc. on the surface of the solid product, and then dry at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com