Fluid-cooling device for a turbine engine propulsive unit

A technology of turbine engine and cooling device, which is applied in the direction of engine cooling, turbine/propulsion device cooling, engine components, etc., and can solve problems such as reduced propeller efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

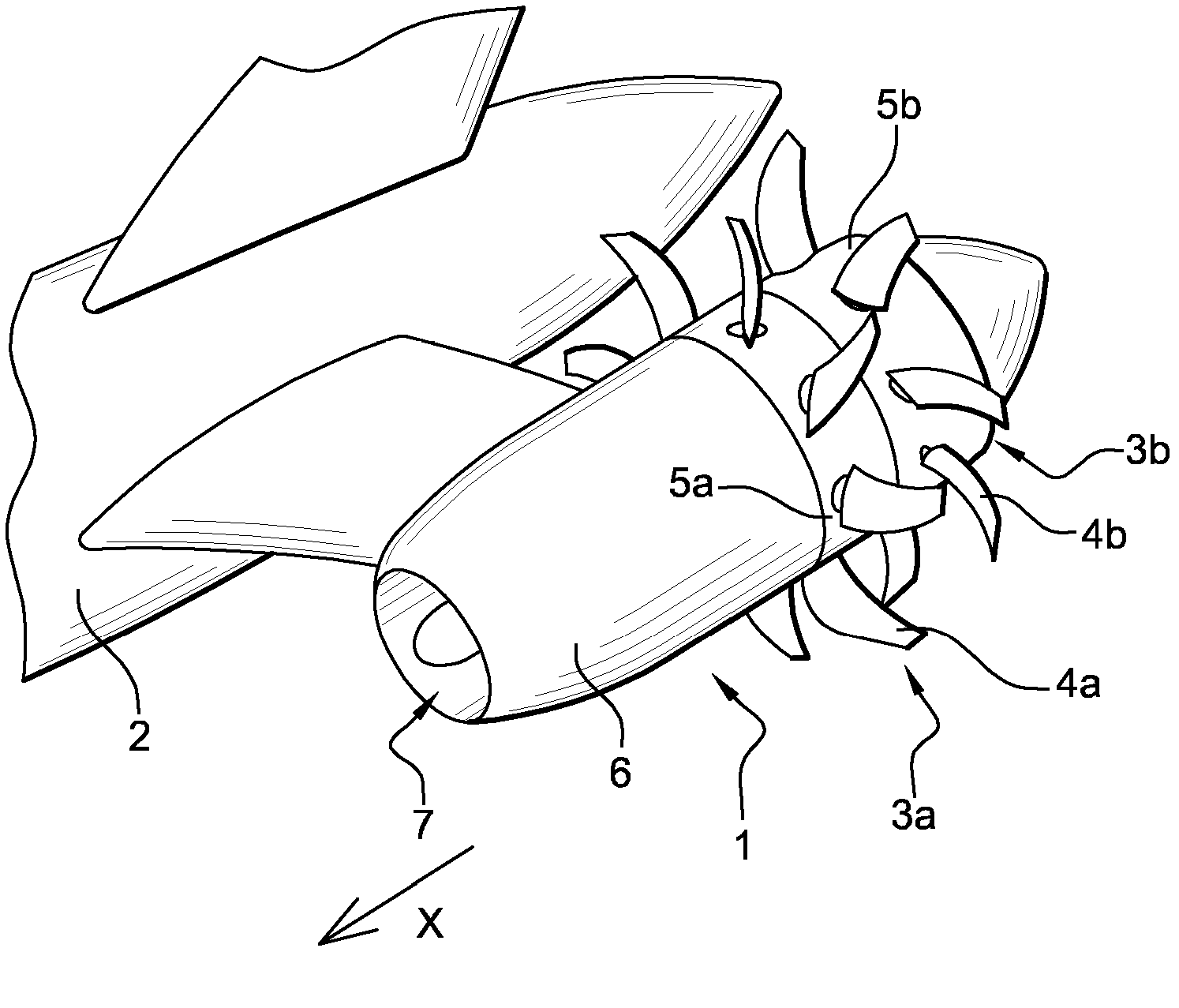

[0046] The present invention is mainly used in propeller 1 of aircraft, as attached figure 1 A propfan aircraft propeller, shown in , is designed to be used on future aircraft. In this embodiment, two propellers 1 are fixed on both sides of the rear of the fuselage 2 of the aircraft by hangers.

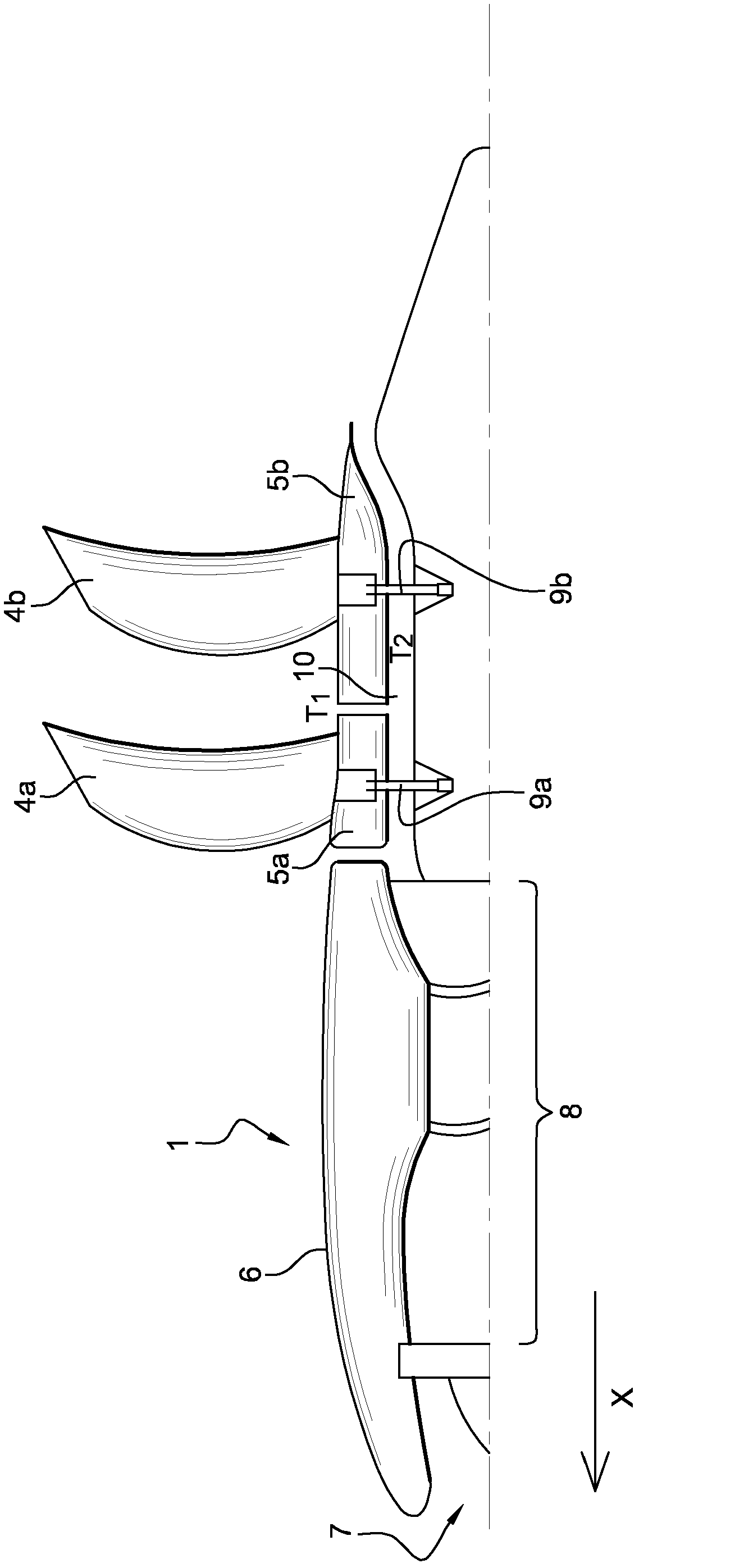

[0047] Here, each propeller 1 includes two counter-rotating rotors 3a, 3b, each rotor includes a set of equidistant blades 4a, 4b, and is arranged at the rear of the propeller 1, each rotor The blades 4a, 4b of 3a, 3b protrude from annular crowns 5a, 5b which move together with the rotor, the outer surface of which rests on the continuation of the casing 6 of the propeller.

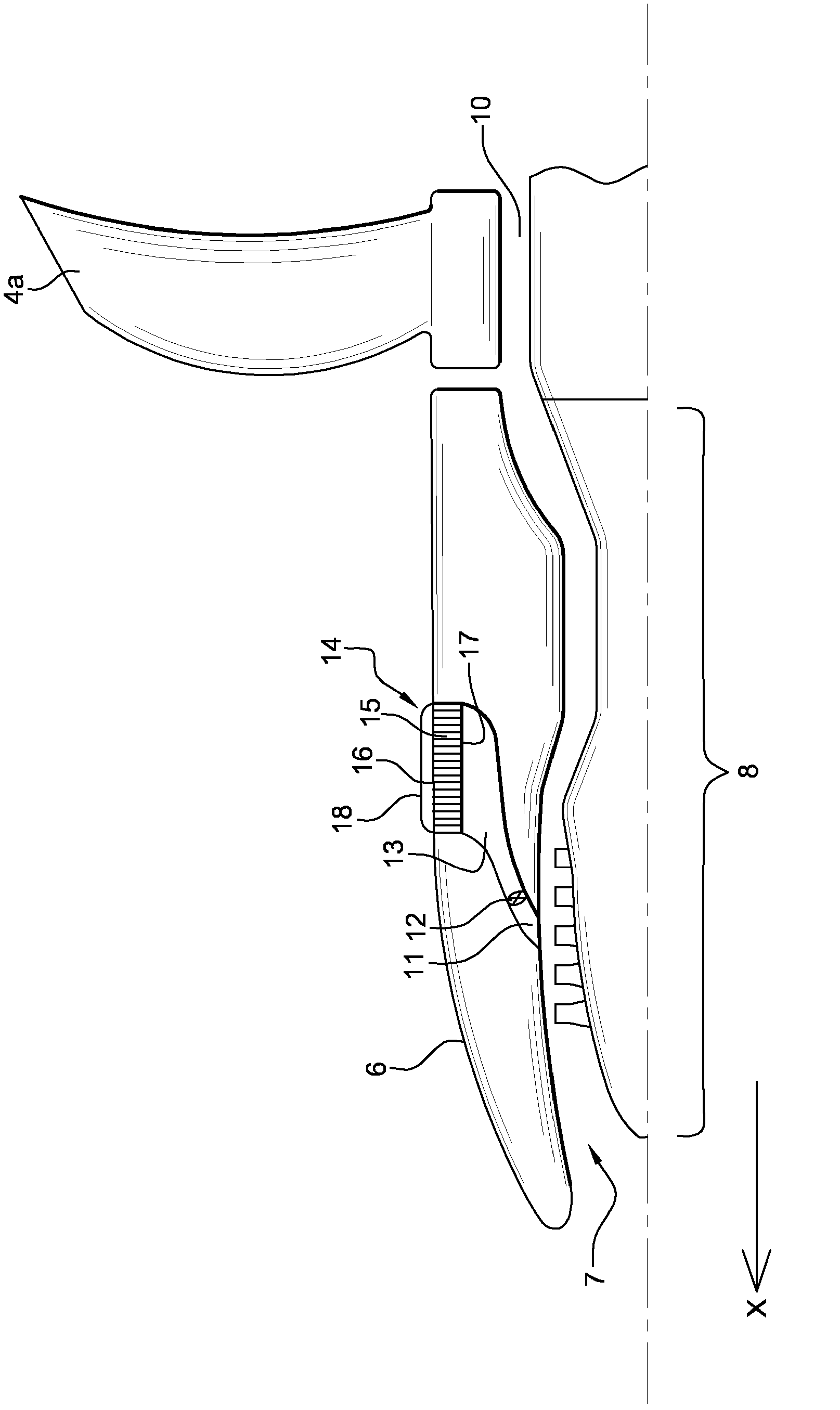

[0048] as attached figure 2 As shown, the propeller 1 comprises an air inlet 7 for supplying air to a turbine engine 8 comprising an axial portion which is driven in rotation when the turbine engine is in operation, said shaft passing through figure 2 A mechanical transmission, not shown, drives the shafts 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com