Equipment for baking and airing bulk tobacco leaves

A kind of equipment and tobacco leaf technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as collapse and bending, low utilization efficiency of curing room, and unsatisfactory curing effect, so as to improve efficiency, improve curing effect, The effect of reducing manual effort and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

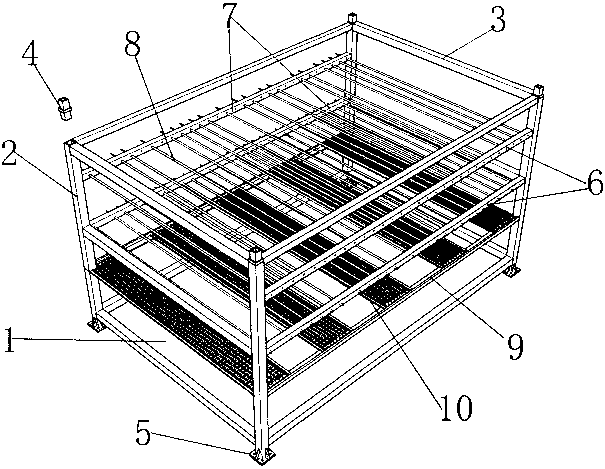

[0018] Such as figure 1 As shown, a bulk tobacco leaf baking and drying equipment includes a support frame 1, the support frame 1 is composed of four columns 2, and the upper and lower ends of two adjacent columns 2 are respectively fixed by pull rods 3; the upper ends of the columns 2 are hollowly placed with The step limit pin 4 is provided with a base plate 5 at the lower end, and the base plate 5 is provided with a pin hole matched with the universal wheel; two guide tubes 6 are provided on one side of the long side of the support frame 1, and the guide tubes 6 are provided with 50mm equal intervals. There are two needle-fixing tubes 7 corresponding to the long side on the other side, which are at the same height as the corresponding guide-pin tubes 6. Fixing hole slots are arranged on the fixing tubes 7; pins 8 are placed through the guide pin holes and the fixing hole slots. Between the equal-height guide needle tube 6 and the needle-fixing tube 7, the diameter of the in...

Embodiment 2

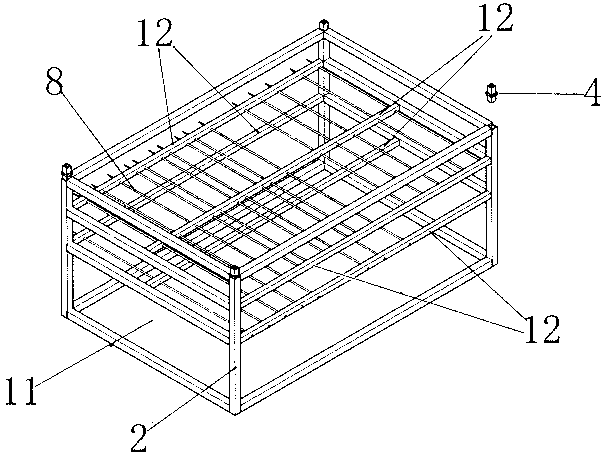

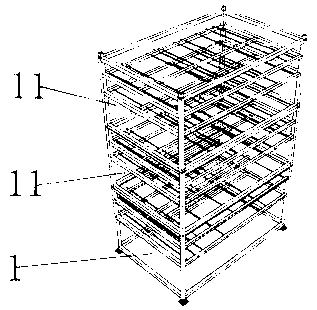

[0021] Such as figure 2 and image 3 As shown, a bulk tobacco leaf baking and drying equipment includes a support frame 1, the support frame 1 is composed of four columns 2, and the upper and lower ends of two adjacent columns 2 are respectively fixed by pull rods 3; the upper ends of the columns 2 are hollowly placed with The step limit pin 4 is provided with a base plate 5 at the lower end, and the base plate 5 is provided with a pin hole matched with the universal wheel; two guide tubes 6 are provided on one side of the long side of the support frame 1, and the guide tubes 6 are provided with 60mm equal intervals. There are two needle-fixing tubes 7 corresponding to the long side on the other side, which are at the same height as the corresponding guide-pin tubes 6. Fixing hole slots are arranged on the fixing tubes 7; pins 8 are placed through the guide pin holes and the fixing hole slots. Between the guide needle tube 6 and the needle fixing tube 7 at the same height, t...

Embodiment 3

[0025] The specific embodiment is the same as the embodiment 2, except that: the outer side of the needle guide tube 6 is provided with a fixing piece; the guide needle tube 6 is provided with through guide pin holes at equal intervals of 70 mm; the diameter of the insertion pin 8 is 7 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com