Method and system for preventing catalyst blockage

A technology of catalyst and ash filter net, which is applied in the field of selective catalytic reduction reactor protection, can solve the problems of catalyst pore blockage, complex vibrating hammer mechanism, high wind speed of filter screen flow, etc., and achieve the effect of continuous operation, safe and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

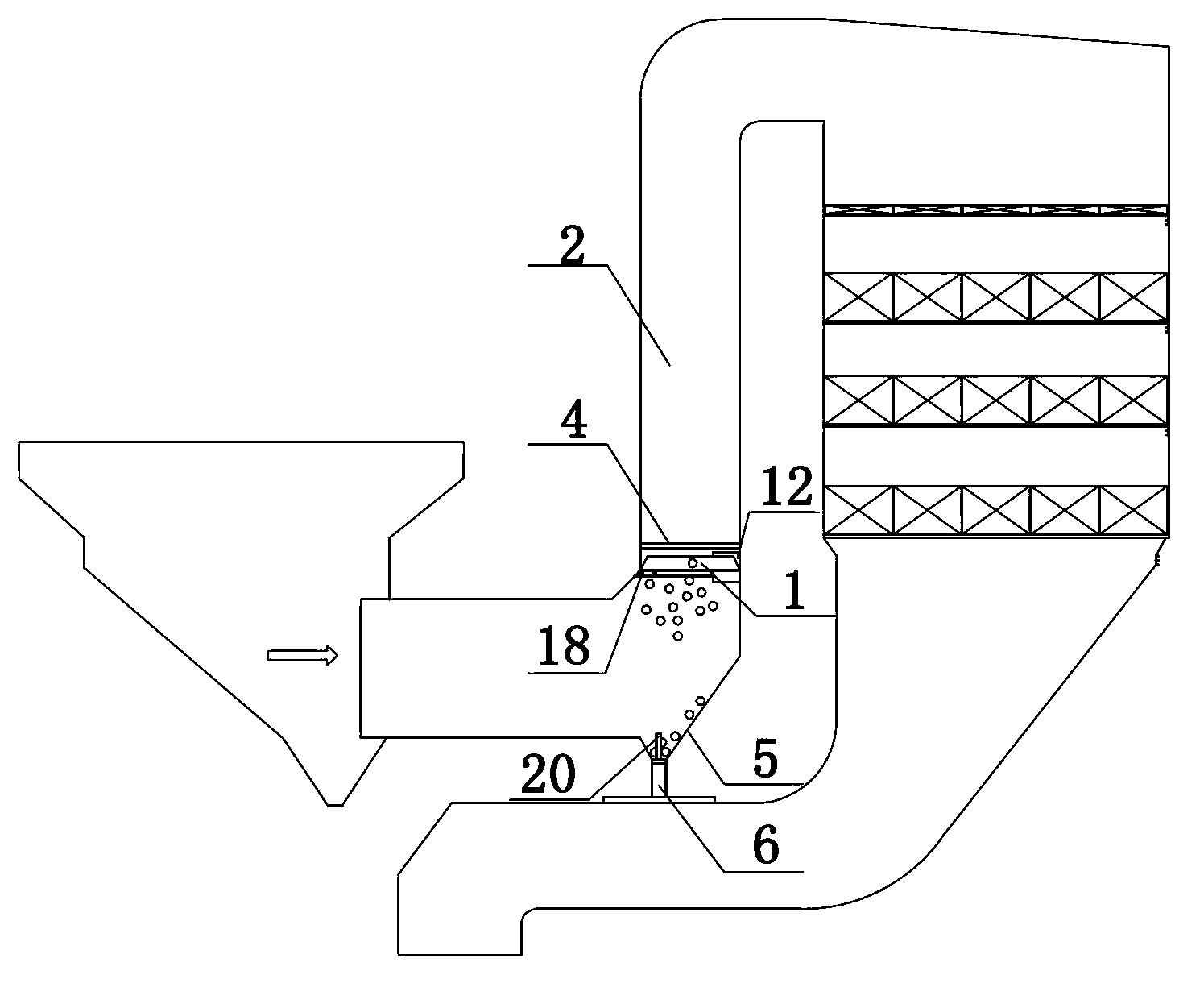

[0026] Embodiment 1 of the present invention: as figure 1 As shown, a system for preventing catalyst clogging includes a longitudinal flue 2 and a transverse flue 3. The longitudinal flue 2 is provided with an A dust filter 1, and only one end of the A dust filter 1 is movably connected with the longitudinal flue 2. , A zipper rapping device 4 is connected to the top of A dust filter net 1, A ash hopper 5 is arranged under A ash filter net 1, A ash hopper level meter 20 is arranged in A ash hopper 5, and the lower end of A ash hopper 5 is connected to A The discharge device 6 is connected. Since there is a dust filter net in the longitudinal flue, a zipper rapping device is arranged above the dust filter net, and an ash hopper is provided under the ash filter net, and the ash hopper is connected to the discharge device, which can not only prevent dust with a particle size of 4 cm or more The particles enter the catalyst layer, and the clogged dust on the ash filter can be dis...

Embodiment 2

[0036] Embodiment 2 of the present invention: as figure 1 As shown, a system for preventing catalyst clogging includes a longitudinal flue 2 and a transverse flue 3. The longitudinal flue 2 is provided with an A dust filter 1, and only one end of the A dust filter 1 is movably connected with the longitudinal flue 2. , A zipper rapping device 4 is connected to the top of A ash filter net 1, A zipper rapping device 4 is connected to A ash filter net 1, A ash hopper 5 is arranged under A ash filter net 1, A ash hopper 5 is provided with A The ash hopper level gauge 20, the lower end of the A ash hopper 5 is connected with the A discharge device 6. Since there is a dust filter net in the longitudinal flue, a zipper rapping device is arranged above the dust filter net, and an ash hopper is provided under the ash filter net, and the ash hopper is connected to the discharge device, which can not only prevent dust with a particle size of 4 cm or more The particles enter the catalyst ...

Embodiment 3

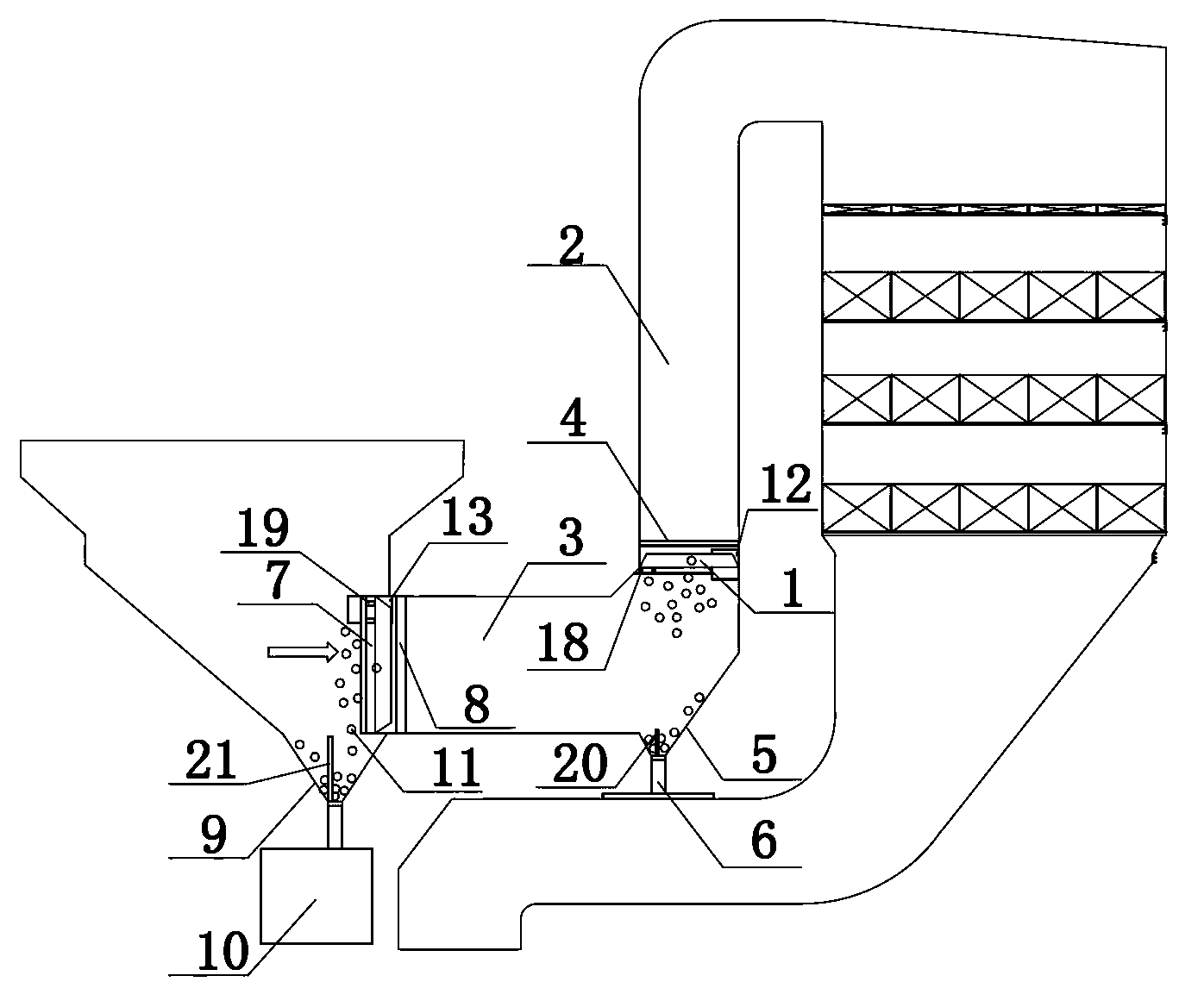

[0046] Embodiment 3 of the present invention: as figure 2 As shown, a system for preventing catalyst clogging includes a longitudinal flue 2 and a transverse flue 3. The longitudinal flue 2 is provided with an A dust filter 1, and only one end of the A dust filter 1 is movably connected with the longitudinal flue 2. , A zipper rapping device 4 is connected to the top of A ash filter net 1, A zipper rapping device 4 is connected to A ash filter net 1, A ash hopper 5 is arranged under A ash filter net 1, A ash hopper 5 is provided with A The ash hopper material level gauge 20, the lower end of the ash hopper 5 of A is connected with the discharge device 6 of A; the ash filter net 7 of B is arranged in the transverse flue 3, and only one end of the ash filter net 7 of B is flexibly connected with the transverse flue 3; One side of the ash net 7 is connected to the B zipper rapping device 8, the B zipper rapping device 8 is connected to the B ash filter net 7, and the B ash hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com