Device for processing metallic workpiece

A technology for processing devices and metal workpieces, applied in metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, complicated processing operations, high cost of mechanical polishing equipment, etc., and achieve simple operation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

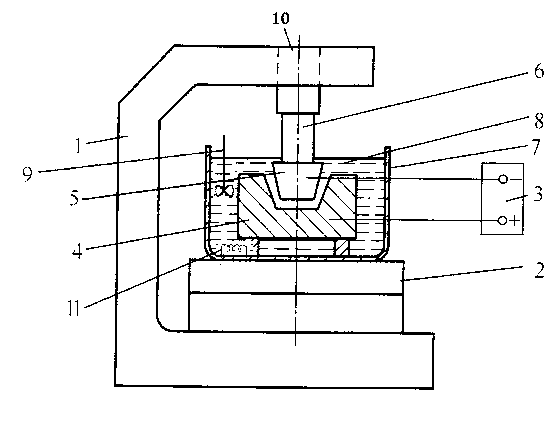

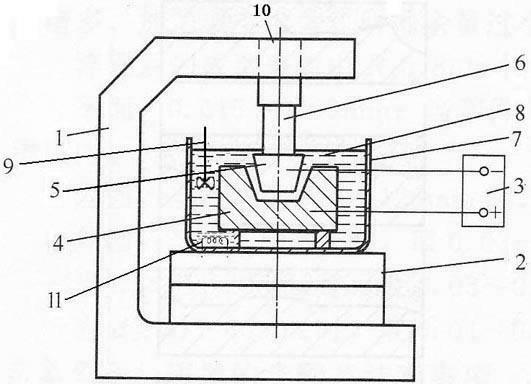

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0014] like figure 1 As shown, a metal workpiece processing device according to the present invention, wherein the workbench 2 is arranged on the base of the machine tool 1, the workbench 2 is equipped with an electrolyte tank 7, and the electrolyte tank 7 is equipped with an electrolytic solution Liquid 8, the workpiece 4, and the tool 5 are all immersed in the electrolyte 8. In order to ensure the corrosion resistance of the electrolyte tank, the inner wall of the electrolyte tank is also provided with an epoxy glass fiber reinforced plastic protective film. In order to ensure the workpiece processing efficiency The stability of the electrolytic cell is also provided with a constant temperature device; the two ends of the feed spindle 6 are respectively connected with the workpiece 4 and the servo mechanism 10. In order to facilitate the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com