Processing method for pinion of automobile steering device

A technology of automobile steering gear and processing method, which is applied to the processing field of automobile steering gear pinion, can solve the problems of long processing time, waste of raw materials, long process flow, etc., and achieves the effects of saving materials, high precision and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

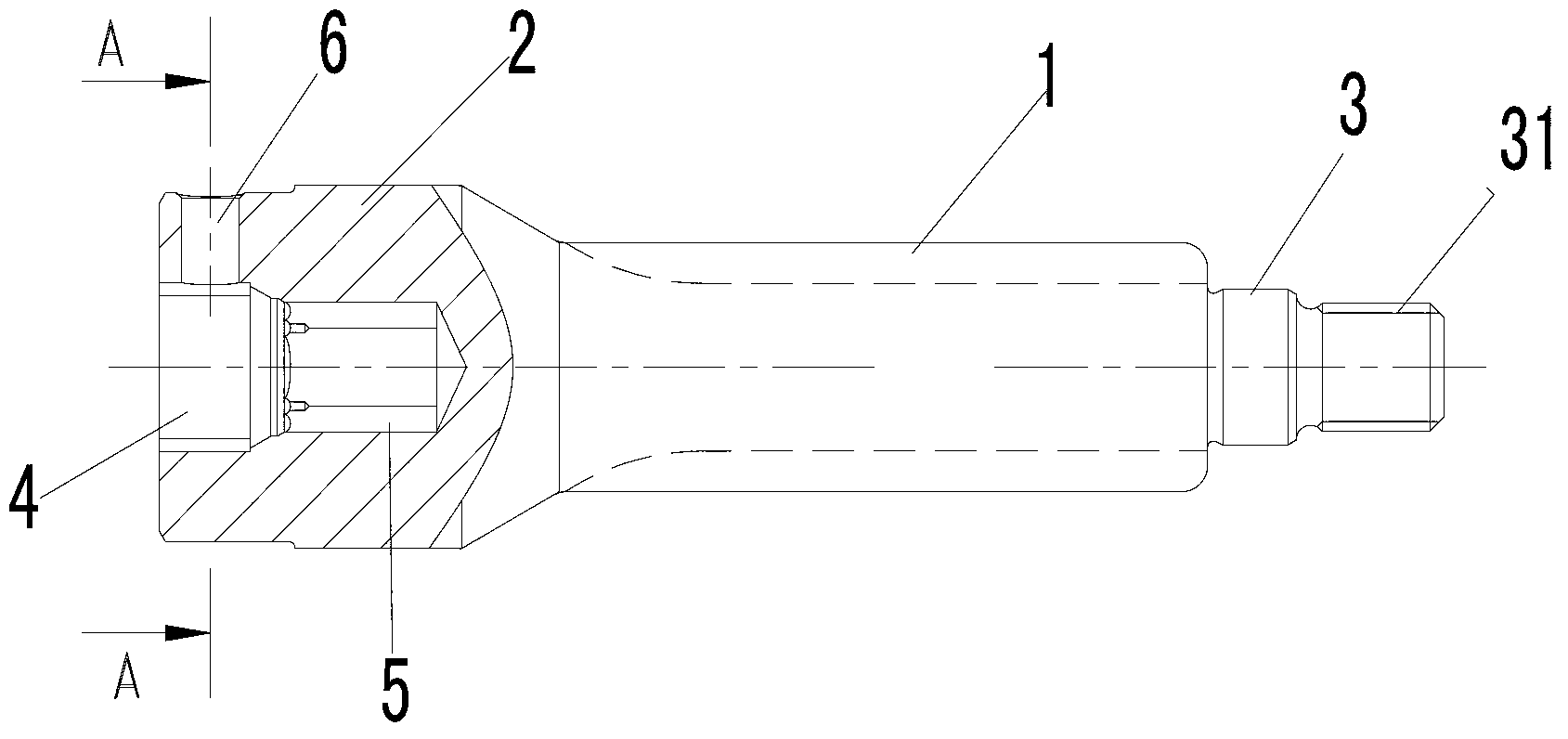

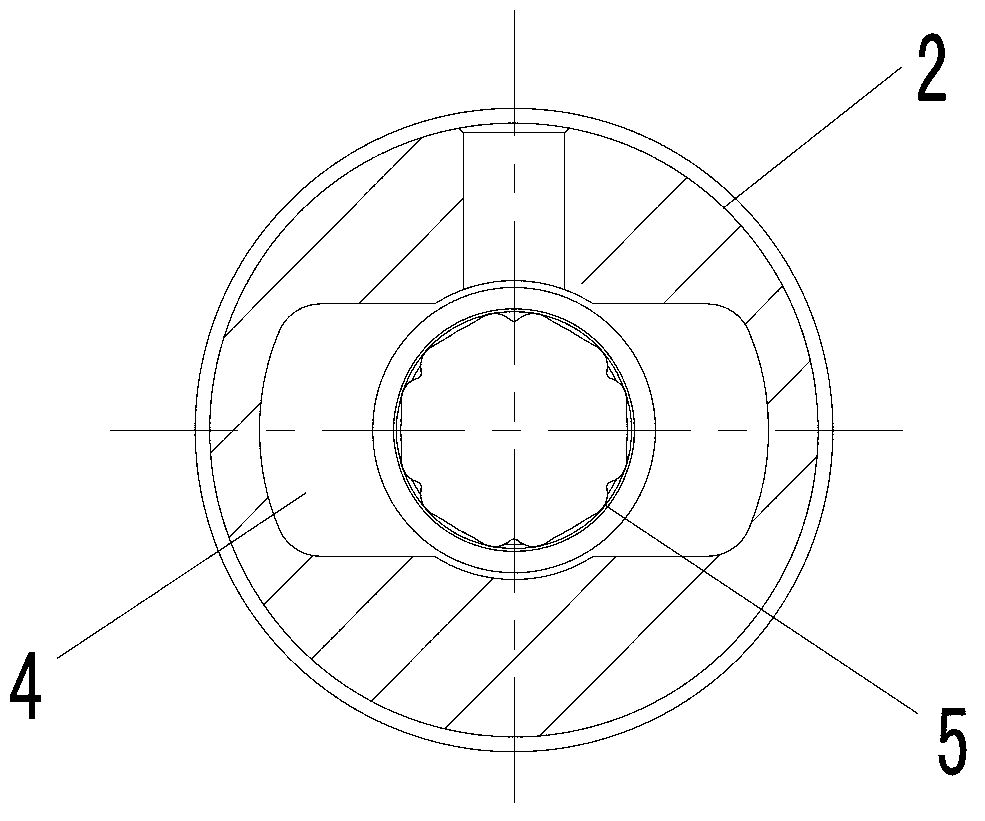

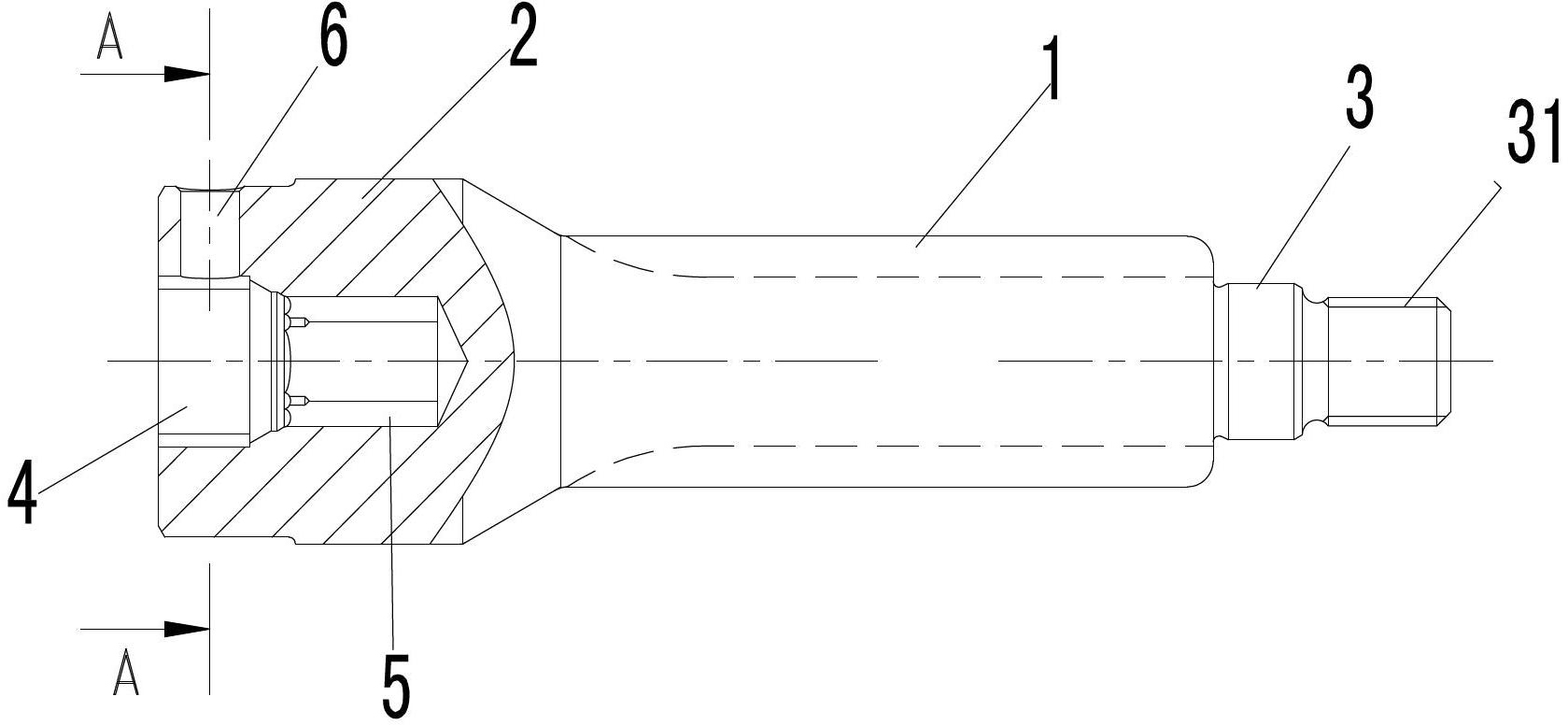

[0031] see figure 1 , with reference to figure 2 , the processing method of automobile steering gear pinion of the present invention, is to be raw material with 16MnCr5 tool steel bar, adopts the step processing that following order is carried out:

[0032] Make the workpiece blank, cut a section of 16MnCr5 tool steel bar, pickling, cold drawing, straightening, sawing, tempering, shot blasting, first phosphorus saponification, first cold extrusion to form a large end long groove, flat Small end, the second cold extrusion to form the inner spline hole of the big end, tempering, the second phosphorus saponification, the third cold extrusion integral molding, tempering, shot blasting, turning the big end, chamfering, drilling small End center hole, grinding big end 60° hole and anti-rust, processing and processing into a workpiece blank with specifications equivalent to the automobile steering gear pinion; the workpiece blank has gear segment 1, big end 2, small end 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com