Production technology of plastic trays and packing boxes

A production process and packaging box technology, which is applied in the production process field of blister trays and packaging boxes, and can solve the problems of heavy weight, easy to be affected by moisture, waste of masterbatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific technical solutions of the present invention will be further described below in conjunction with the embodiments.

[0013] The invention provides a production process for blister trays or boxes, comprising the following steps:

[0014] a. Put the PET, PS or PVC coiled material into the gluing machine, and the gluing machine heats up to apply gluing to the coiled material;

[0015] b. Make the EPS board according to the shape of the tray or box, and punch a plurality of holes for the airflow to pass through the EPS board;

[0016] c. Put the glued PET, PS or PVC coil on the blister machine, place the EPS board made in step b on the adsorption chassis, and absorb the glued PET, PS or PVC on the outside of the EPS board or box surface;

[0017] d. Place the product obtained in step c on the edge ironing machine, iron the four sides flat, and finally install plastic legs;

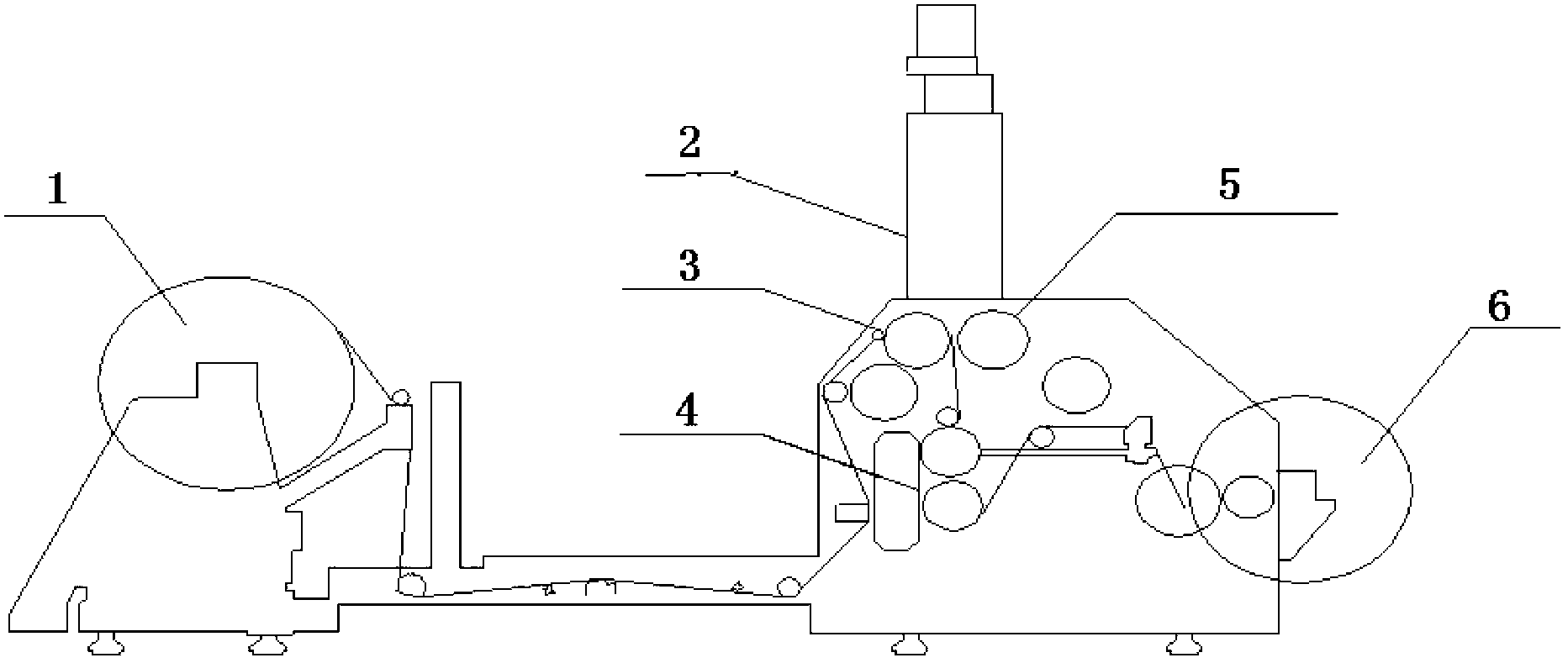

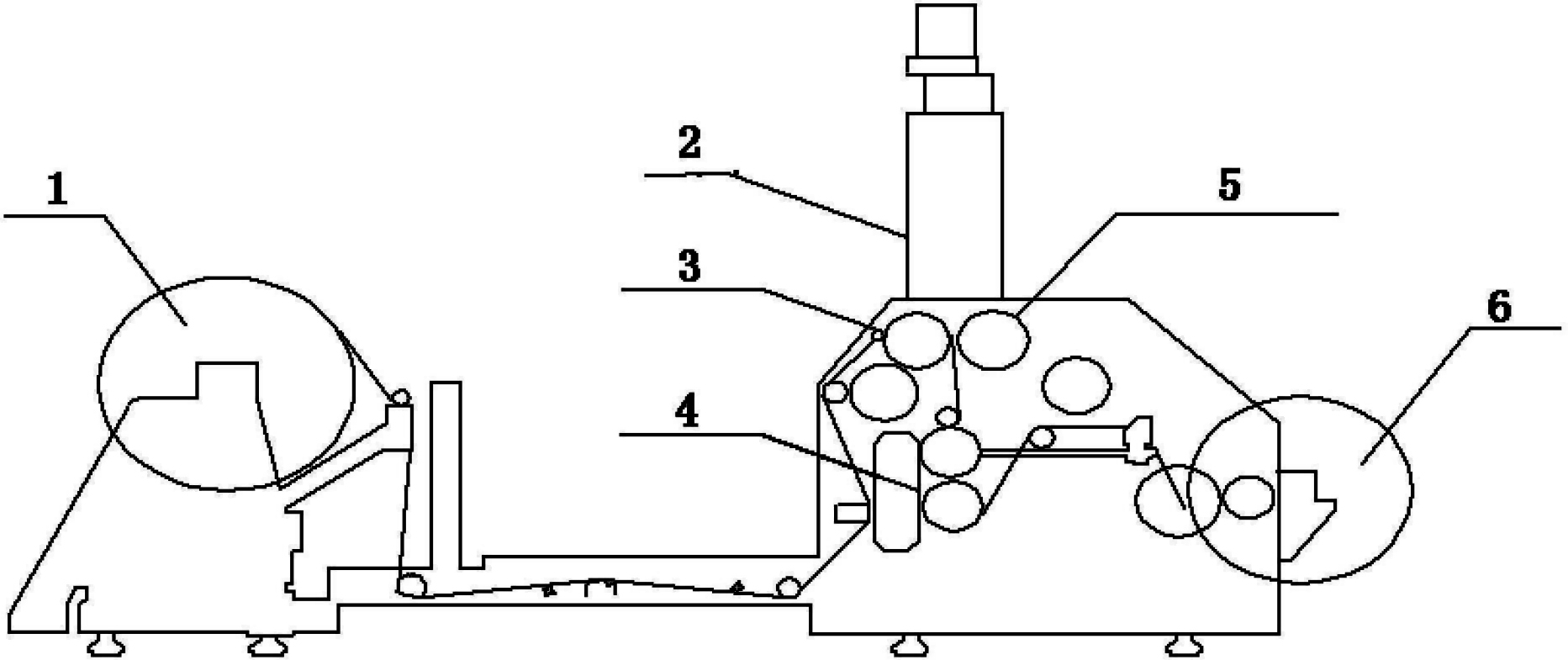

[0018] Among them, refer to figure 1 As shown, the gluing machine includes a dischar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap