Scissor type lifting disc stacking roller conveyor

A technology of pallet rollers and conveyors, which is applied in the field of cargo palletizing and transportation, can solve the problems of time-consuming, labor-intensive and low efficiency, and achieve the effects of reducing staffing, reducing labor intensity and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

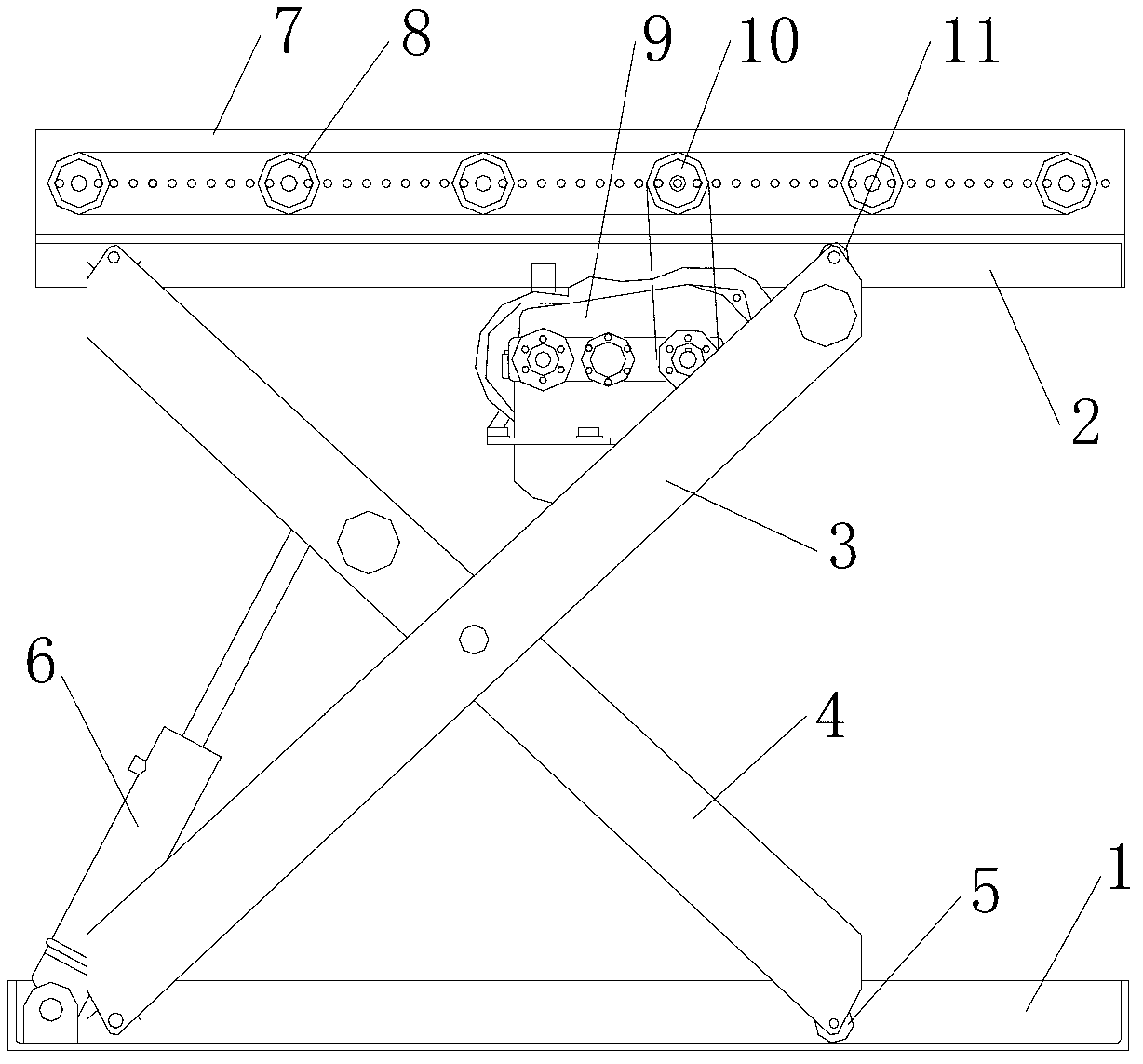

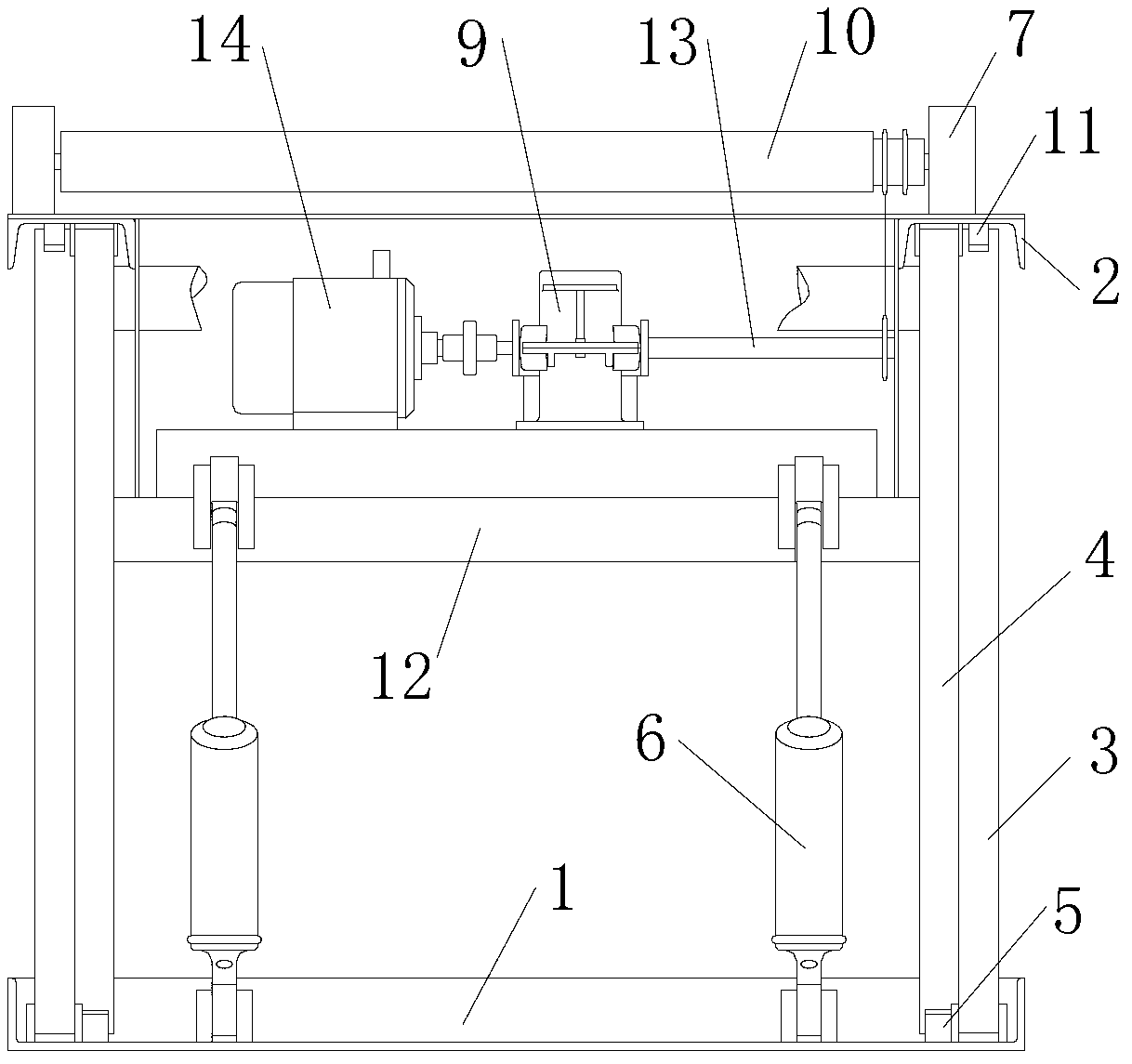

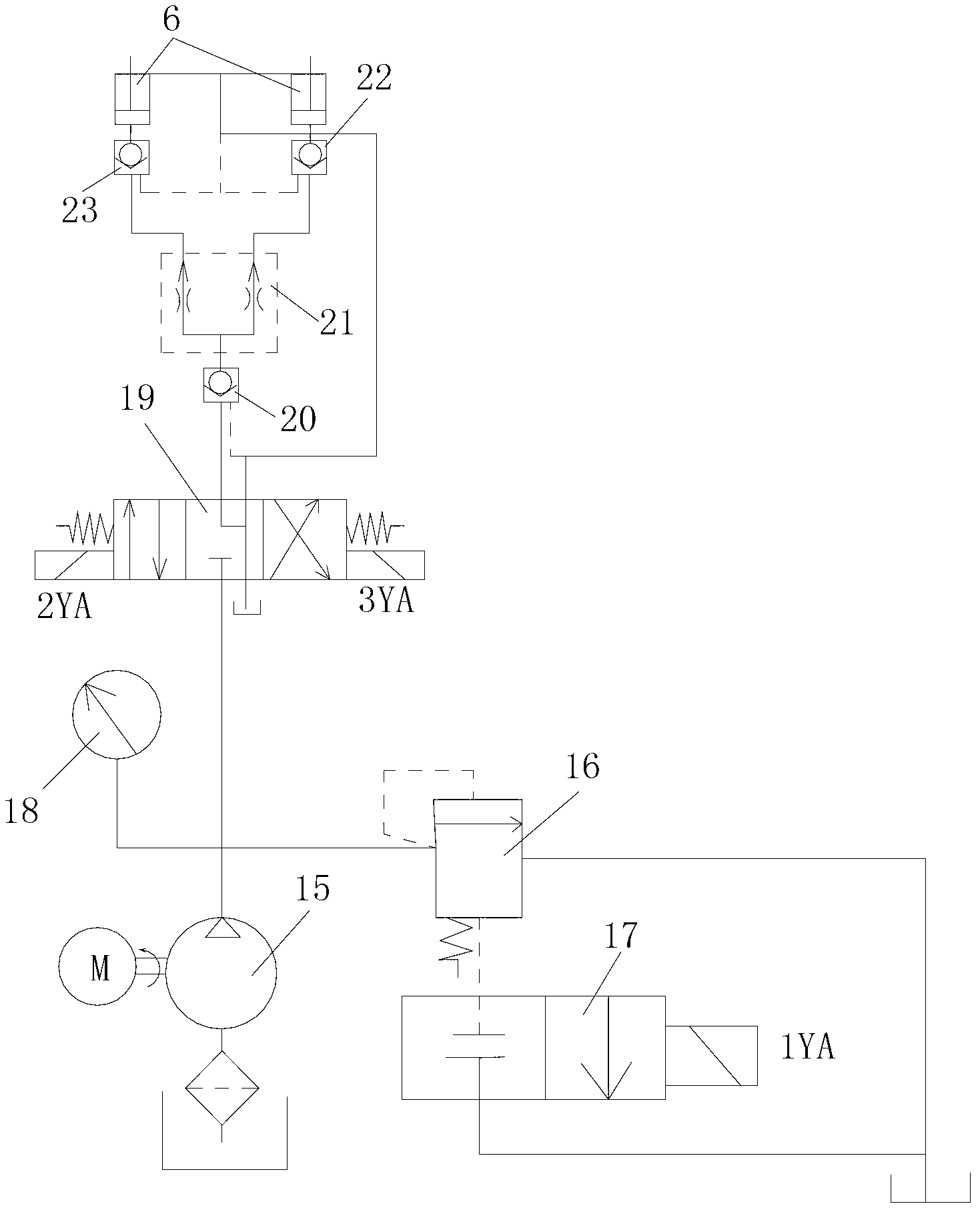

[0015] The scissor type lifting code disc roller conveyor of the present invention mainly includes a lifting mechanism, a roller conveying mechanism and a lifting driving mechanism, the roller conveying mechanism is arranged on the lifting mechanism, and the lifting mechanism is connected with the lifting driving mechanism. The lifting mechanism is designed to realize the lifting of the roller conveying mechanism and the pallet containing the goods on it, so as to facilitate the handling of workers. The lifting mechanism is driven by the lifting drive mechanism to rise and fall, and the roller conveying mechanism realizes the horizontal conveying of goods.

[0016] The specific structure of the lifting mechanism, the roller conveying mechanism and the lifting drive mechanism is as follows: figure 1 and figure 2 shown.

[0017] The lifting mechanism adopts the scissor lifting structure, mainly including the bottom frame 1, the upper frame 2 and the scissors. Both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com