Ultraviolet curing woodware colored paint coating and preparation method thereof

A UV light and coating technology, used in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: UV curing wood color paint coating

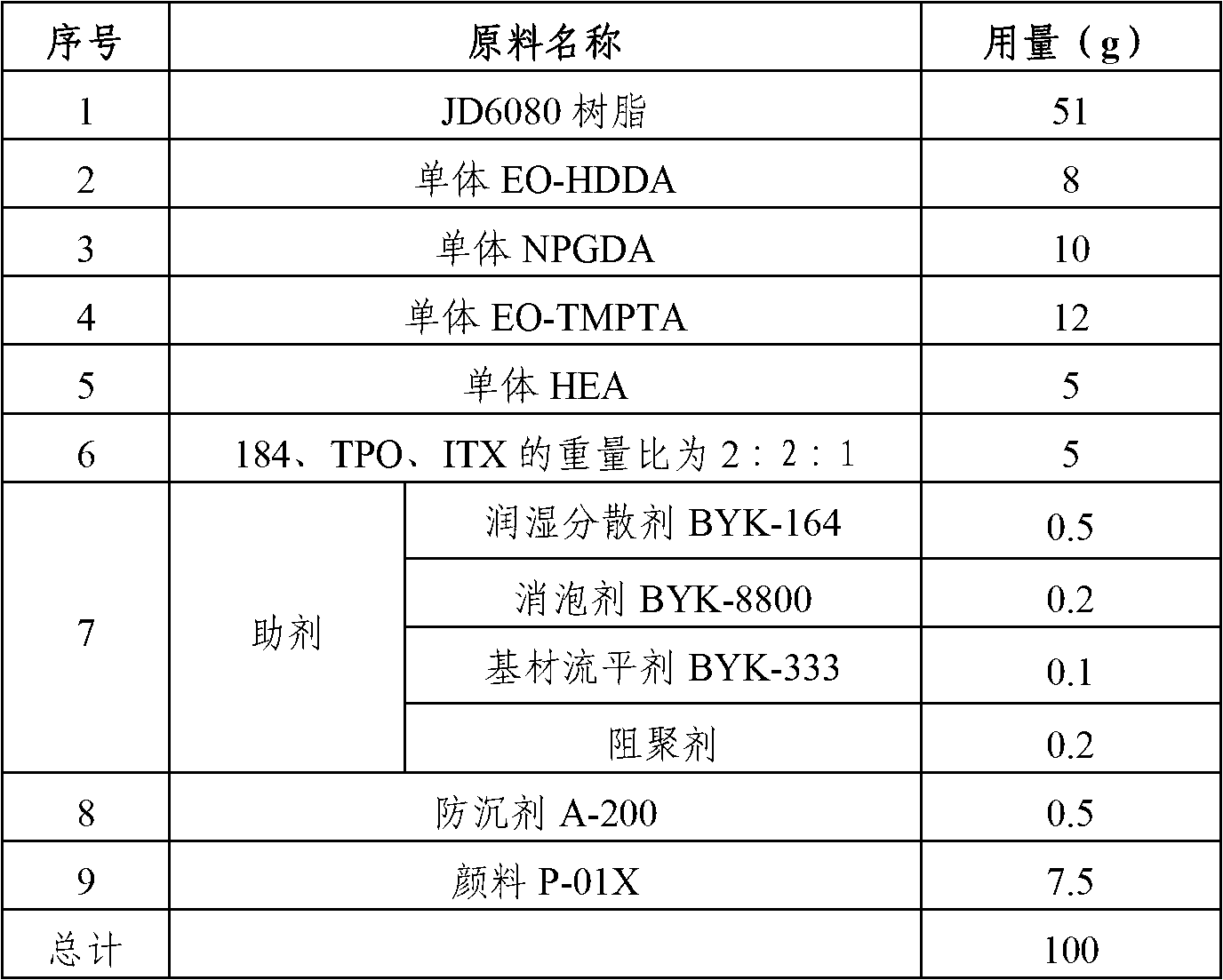

[0048] 1. Composition of raw materials:

[0049]

[0050] 2. Preparation method

[0051] 1) Weigh each component according to the proportion, disperse JD6080 resin, monomer EO-HDDA, monomer NPGDA, monomer EO-TMPTA, monomer HEA at 1500 rpm for 20 minutes, then add anti-settling under stirring Agent A-200, polymerization inhibitor, dispersed for 10 minutes at 1500 rpm to obtain mixture 1;

[0052] 2) Add photoinitiator 184, TPO, ITX and defoamer BYK-8800 to mixture 1, and disperse for 5-10 minutes at 1200 rpm; then add wetting and dispersing agent BYK-164, substrate leveling agent BYK- 333, disperse at 1200 rpm for 10-15 minutes, then add pigment P-01X and disperse at high speed at 1500 rpm for 20 minutes to obtain the product.

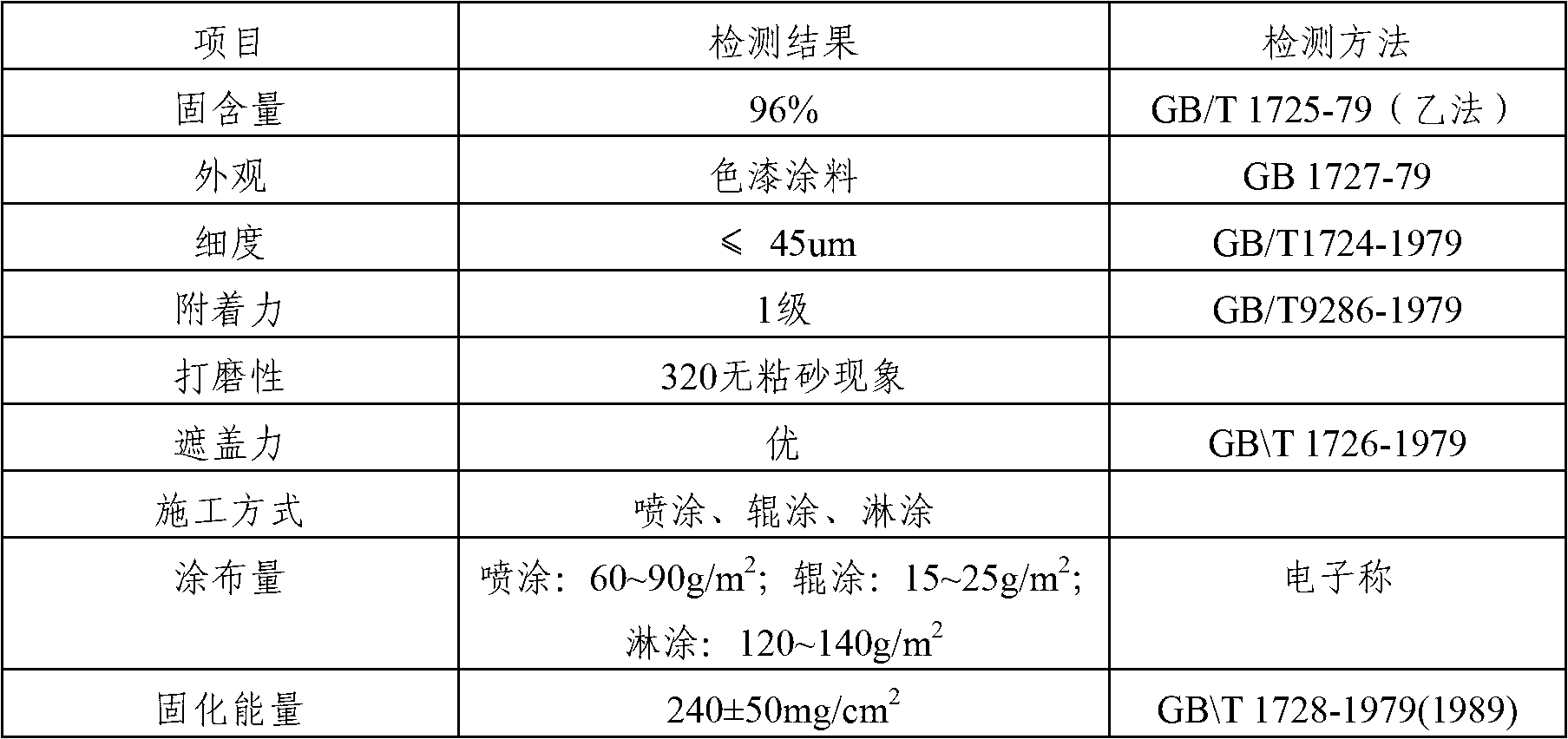

[0053] 3. Coating method: apply the color paint on the substrate (construction process: wooden substrate→UV transparent bottom→full dry sanding→UV color paint). at 320mj / cm 2 (Equipment c...

Embodiment 2

[0057] Embodiment 2: UV curing wood color paint coating

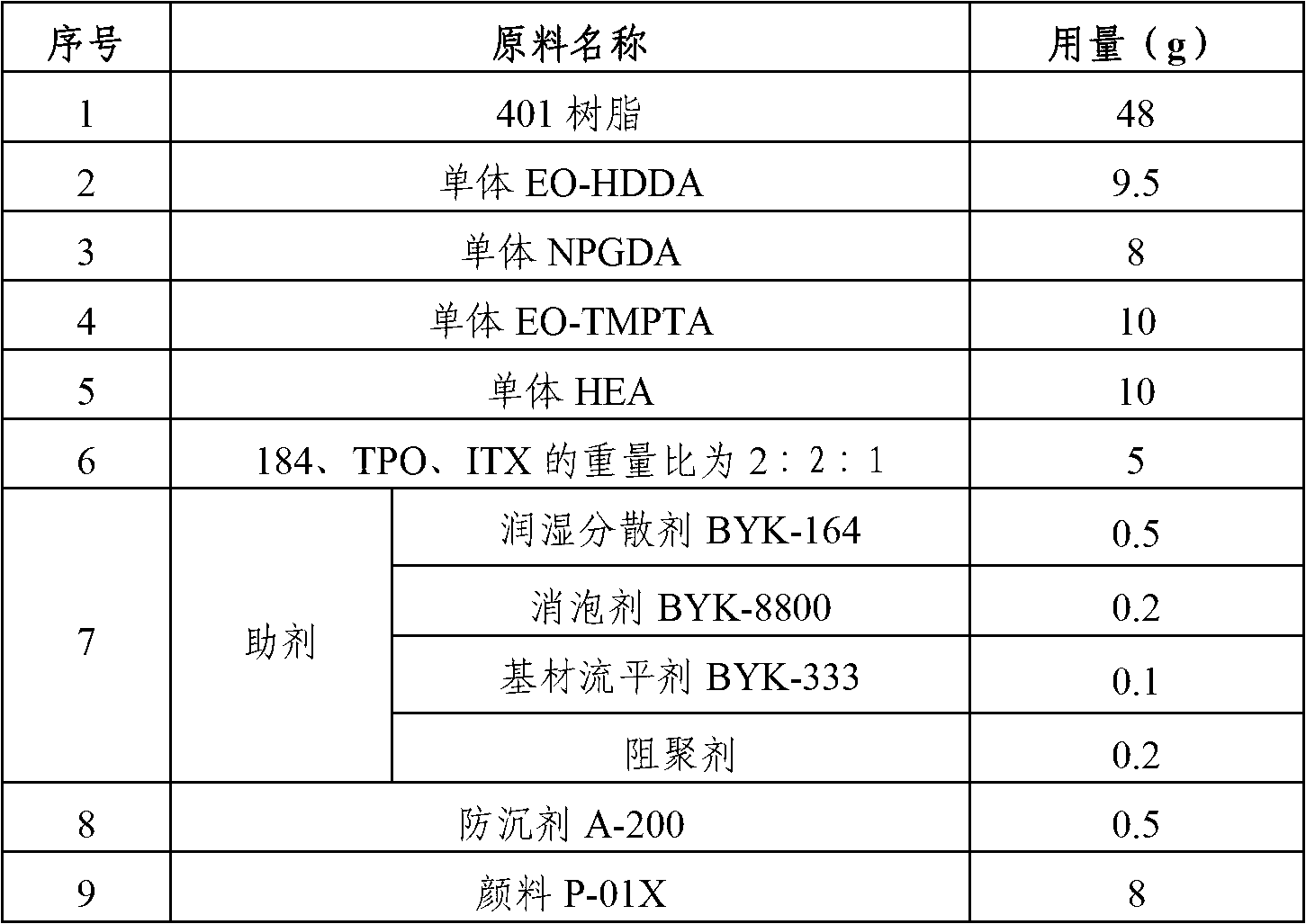

[0058] 1. Composition of raw materials:

[0059]

[0060]

[0061] 2. Preparation method

[0062] 1) Weigh each component according to the ratio, disperse 401 resin and reactive monomers EO-HDDA, NPGDA, EO-TMPTA, HEA at 1500 rpm for 20 minutes, then add anti-settling agent A-200, The polymerization inhibitor was dispersed for 15 minutes according to 1500 rpm to obtain mixture 1;

[0063] 2) Add photoinitiator 184, TPO, ITX, defoamer BYK-8800 to mixture 1, and disperse for 5-10 minutes at 1200 rpm; then add wetting and dispersing agent BYK-164, substrate leveling agent BYK- 333, disperse at 1200 rpm for 10-15 minutes, then add pigment P-01X and disperse at high speed at 1500 rpm for 20 minutes to obtain the product.

[0064] 3. How to use:

[0065] Apply the paint to the substrate (construction process: wooden substrate → UV transparent bottom → dry sanding → UV paint). at 320mj / cm 2 (Equipment conditions: 1 ...

Embodiment 3

[0069] Embodiment 3: UV-cured wood color paint coating

[0070] 1. Composition of raw materials:

[0071]

[0072] 2. Preparation method

[0073] 1) Weigh each component according to the proportion, disperse JD6090 resin and monomer EO-HDDA, NPGDA, EO-TMPTA, HEA at 1500 rpm for 20 minutes, then add anti-settling agent A-200, polymerization inhibitor agent, dispersed for 10-15 minutes according to 1500 rpm to obtain mixture 1;

[0074] 2) Add photoinitiator 184, TPO, ITX, defoamer BYK-8800 to mixture 1, and disperse for 5-10 minutes at 1200 rpm; then add wetting and dispersing agent BYK-164, substrate leveling agent BYK- 333, disperse at 1200 rpm for 10-15 minutes, then add pigment P-01X and disperse at high speed at 1500 rpm for 20 minutes to obtain the product.

[0075] 3. How to use: Apply the color paint to the base material (construction process: wooden base material→UV transparent bottom→full dry sanding→UV color paint). at 320mj / cm 2 (1 gamma lamp and 2 mercury l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap