Method of maintenance and lifting for moving section flue at converter mouth

A hoisting method and the technology of the furnace mouth of the converter, which are applied in the manufacture of converters, etc., can solve the problems of maintenance personnel and the use of mechanical equipment to increase the investment in engineering maintenance costs, affect the production of the owner's factory, prolong the maintenance time, etc., and achieve the reduction of dismantling range, improving demolition efficiency, and reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

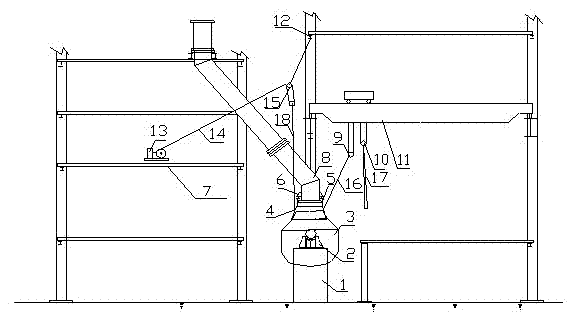

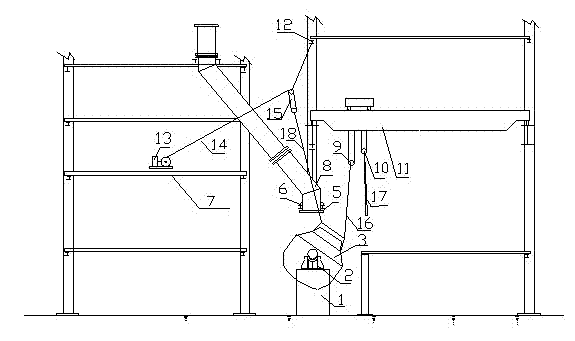

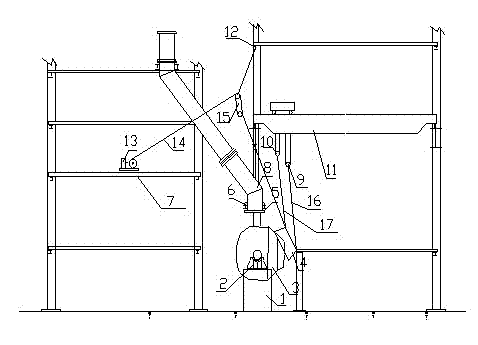

[0019] The invention provides a method for overhauling, dismantling and hoisting the flue of the active section of the furnace mouth of the converter. The construction steps are: 1. Install the hoisting pulley block and the pulley block to drive the hoisting device; 2. Arrange the hoisting steel wire rope and lifting points; 3. Remove the furnace mouth The flue lifting device of the movable section; 4. The flue of the movable section of the furnace mouth is removed. Specific steps are as follows:

[0020] 1. Set up the hoisting pulley block and the pulley block drive winch device:

[0021] The flue 4 of the movable section of the furnace mouth is arranged directly above the furnace mouth of the converter 3, and the converter 3 is supported on the converter foundation 1 through the bearing seat 2, and the converter 3 can be supported by the bearing seat 2 at 360 0 rotate. The flue 4 of the movable section of the furnace mouth is fixed on the support seat 6 of the fixed flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com