Detachable frameless big glass keel dry-hanging method construction system and construction method

A glass dragon and backbone technology, applied to building components, covering/lining, walls, etc., can solve the problems of poor corner treatment of glass wall cylinders, difficult maintenance and replacement, and slow construction speed, achieving good decorative effects and fast construction Fast and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

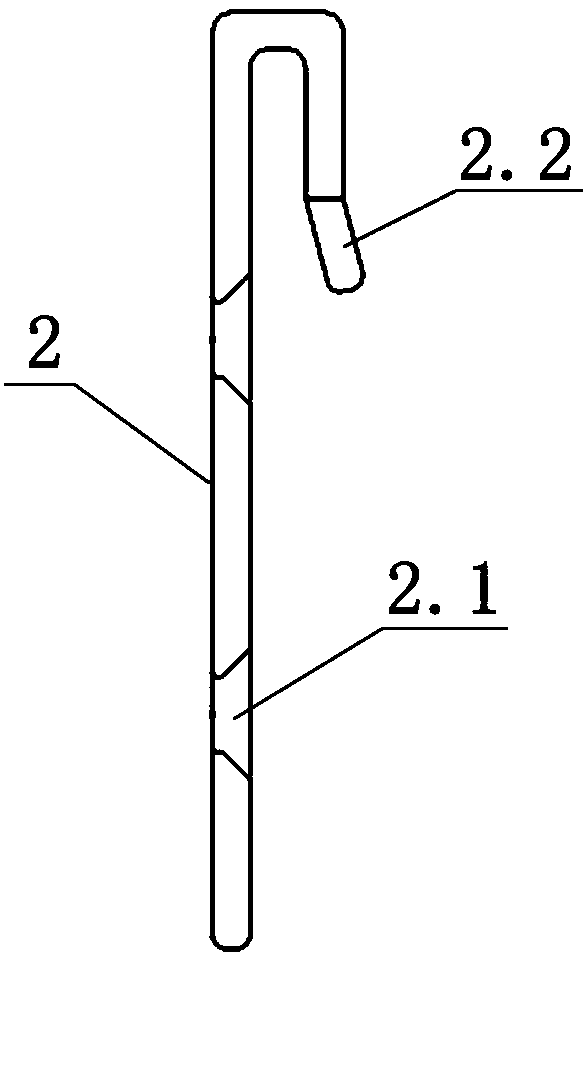

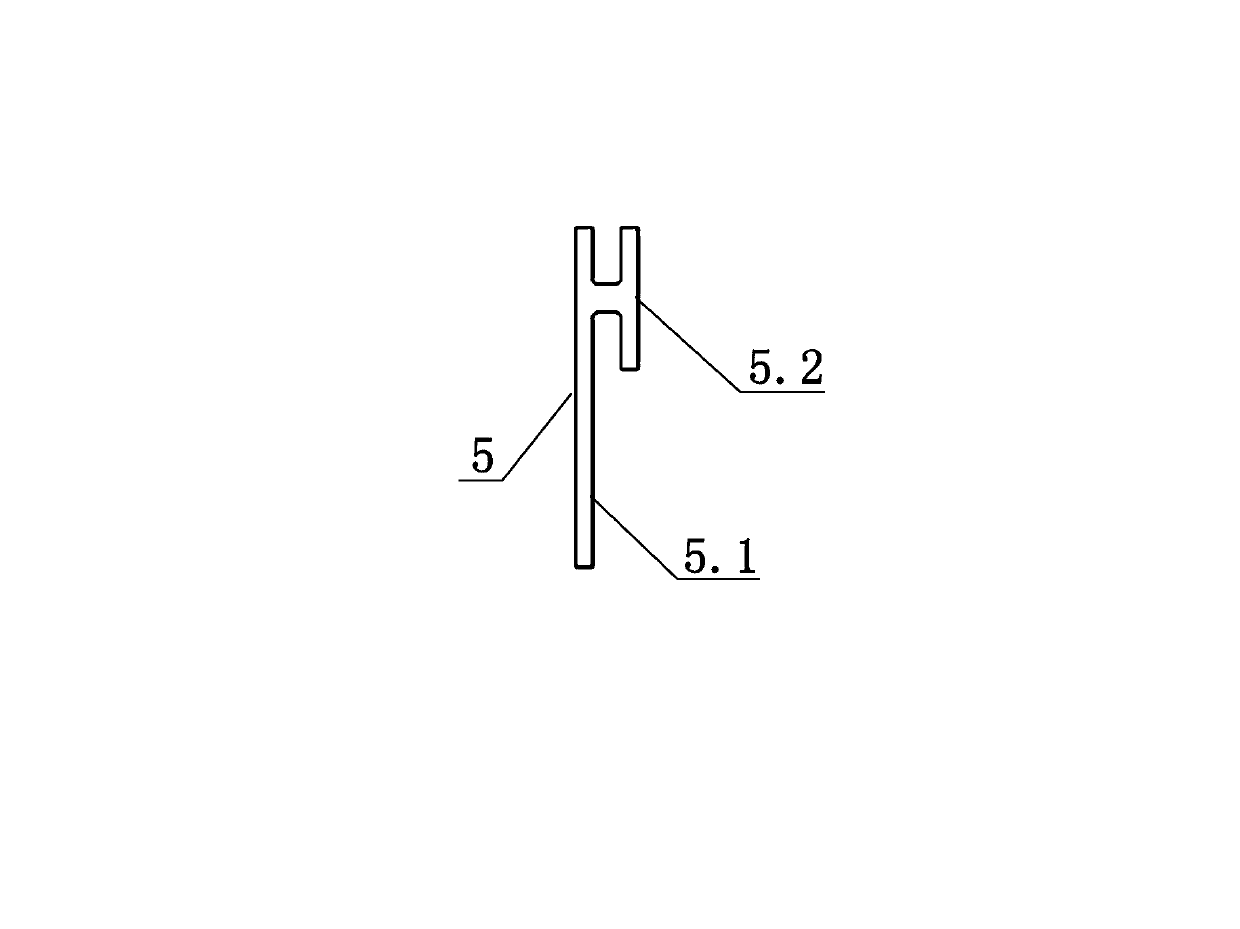

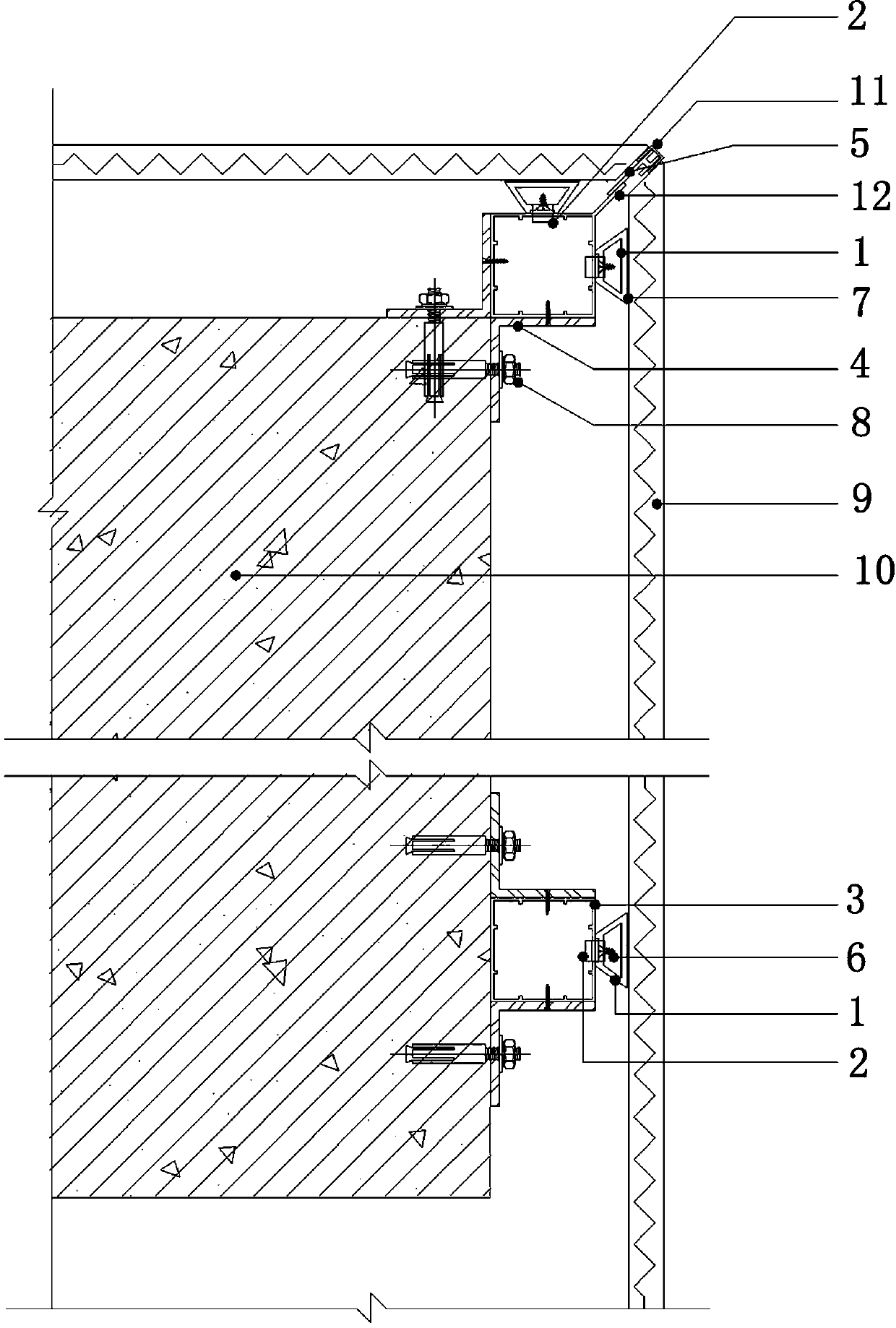

[0046] Examples see figure 1As shown, this detachable frameless large glass keel dry hanging construction system includes aluminum alloy vertical keel 3 installed between wall column surface 10 and glass 9, metal corner code 4, trapezoidal aluminum alloy profile 1 and galvanized Pendant 2. The aluminum alloy vertical keel 3 is a rectangular column structure, and its side facing the glass 9 is vertically spaced with hanging holes 3.1. The left and right side surfaces of the aluminum alloy vertical keel 3 are respectively fixed by the metal corner bracket 4 and the wall column surface 10 . Metal angle code 4 is L shape, and its both sides all have screw holes, metal angle code 4 one side is fixed by screw and aluminum alloy vertical keel 3, and the other side is fixed by expansion bolt 8 and wall column surface 10. The cross-section of the trapezoidal aluminum alloy profile 1 is isosceles trapezoidal, and its lower bottom 1.2 is bonded to the surface of the glass 9 by structur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap