Vacuum hollow glass

A hollow and glass technology, applied in parallel glass structure, window/door improvement, climate change adaptation, etc., can solve the problems of complicated manufacturing process, high manufacturing cost, air extraction sealing hole, unreasonable design, etc., to reduce processing cost , easy operation and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

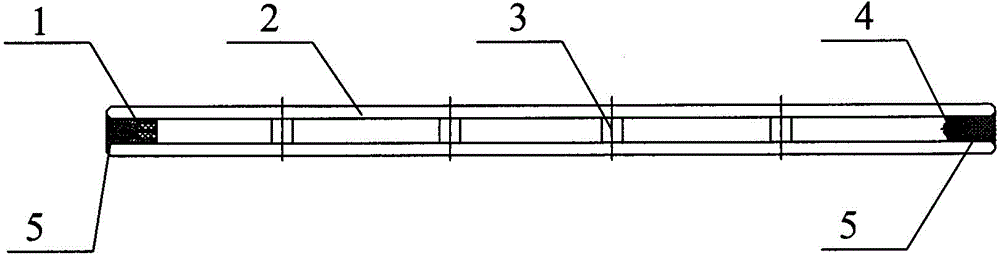

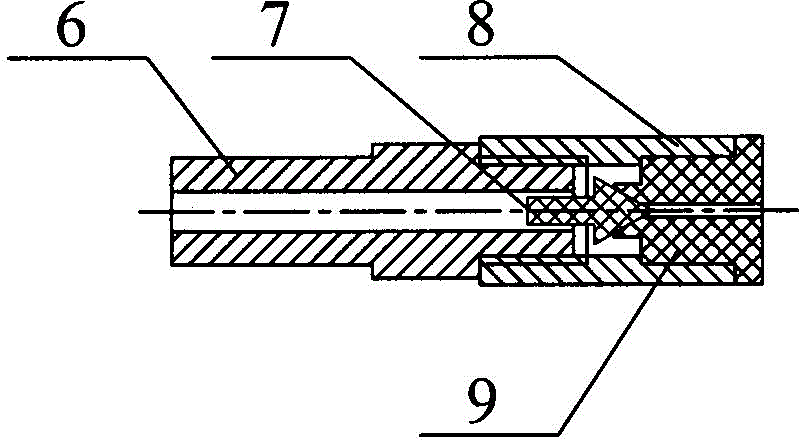

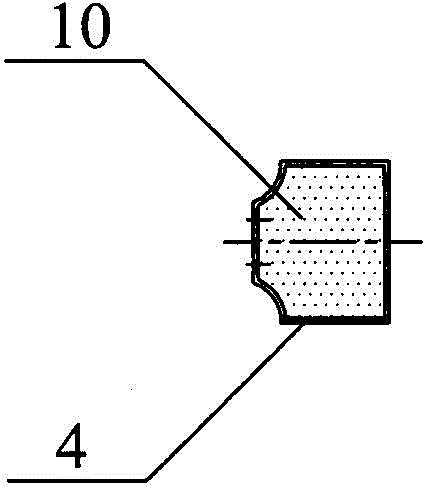

[0012] according to Figure 1~3 The specific structure of the present invention will be described in detail. The vacuum insulating glass consists of common glass plates 2 (ordinary glass plates, tempered glass plates, LOW-E glass plates, etc.) . Among them, there are at least two glass plates 2 in the basic unit, and support members 3 made of weather-resistant hard materials are arranged in a matrix between adjacent glass plates 2, and the shape of the support members 3 can be circular, square, or polygonal. and other geometric shapes, the hard material can be rubber, plastic, etc. Around the basic units separated by matrix-arranged supports 3 , aluminum strips 4 with inner cavities encapsulating desiccant 10 are assembled through weather-resistant sealant 5 . A vacuum pumping device 1 is sealed at the butt joints of the two ends of the aluminum strip 4 surrounding the periphery of the basic unit. Vacuum pumping device 1 comprises parts such as pumping nozzle 6, connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com