Shallow hole drilling machine

A technology for drilling rigs and shallow holes, which is applied to rotary drilling rigs, earth-moving drilling, drilling equipment, etc., can solve the problems of reducing construction efficiency, inconvenient lifting, installation and transportation, and inconvenient transfer, transportation and lifting of shallow-hole drilling rigs. The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

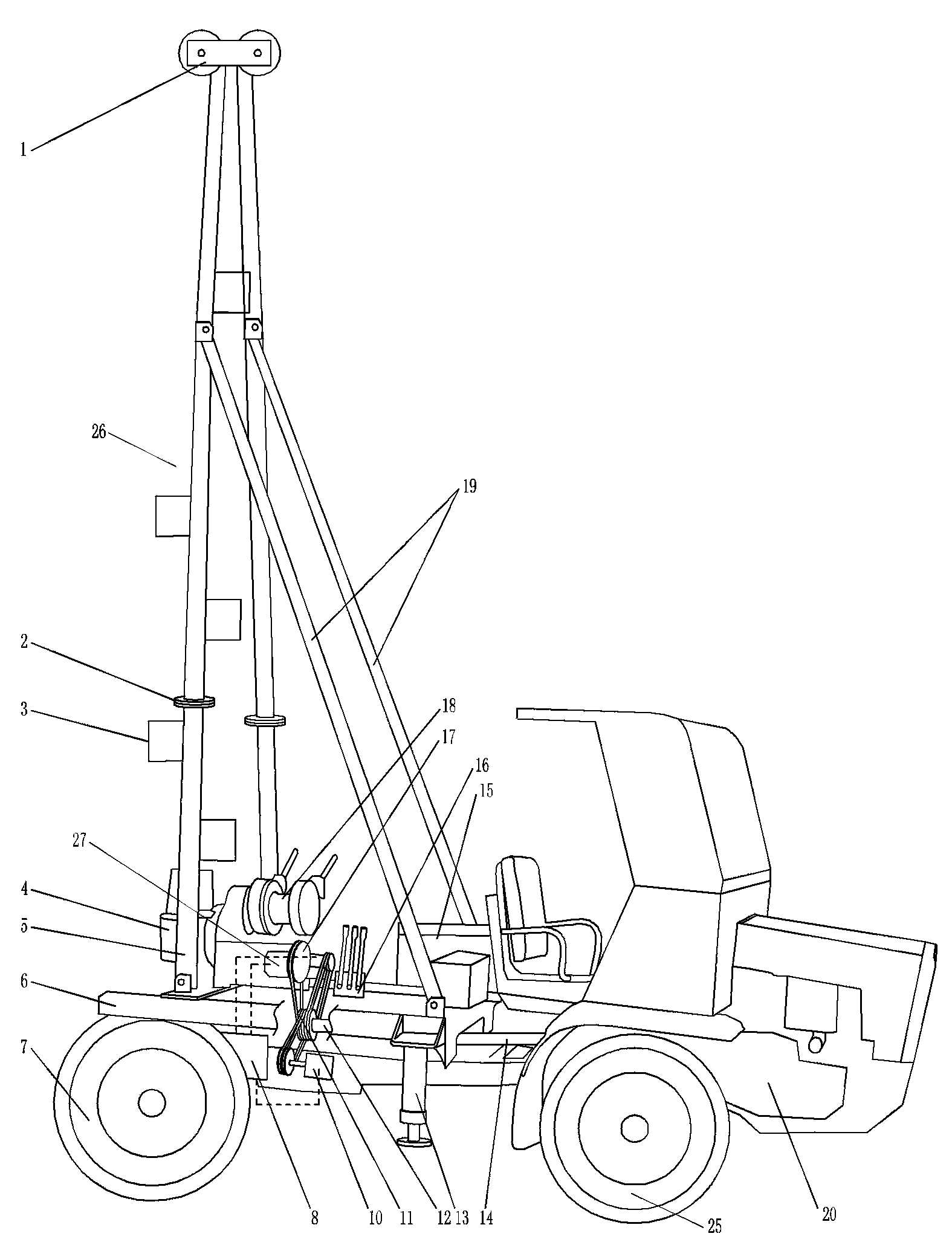

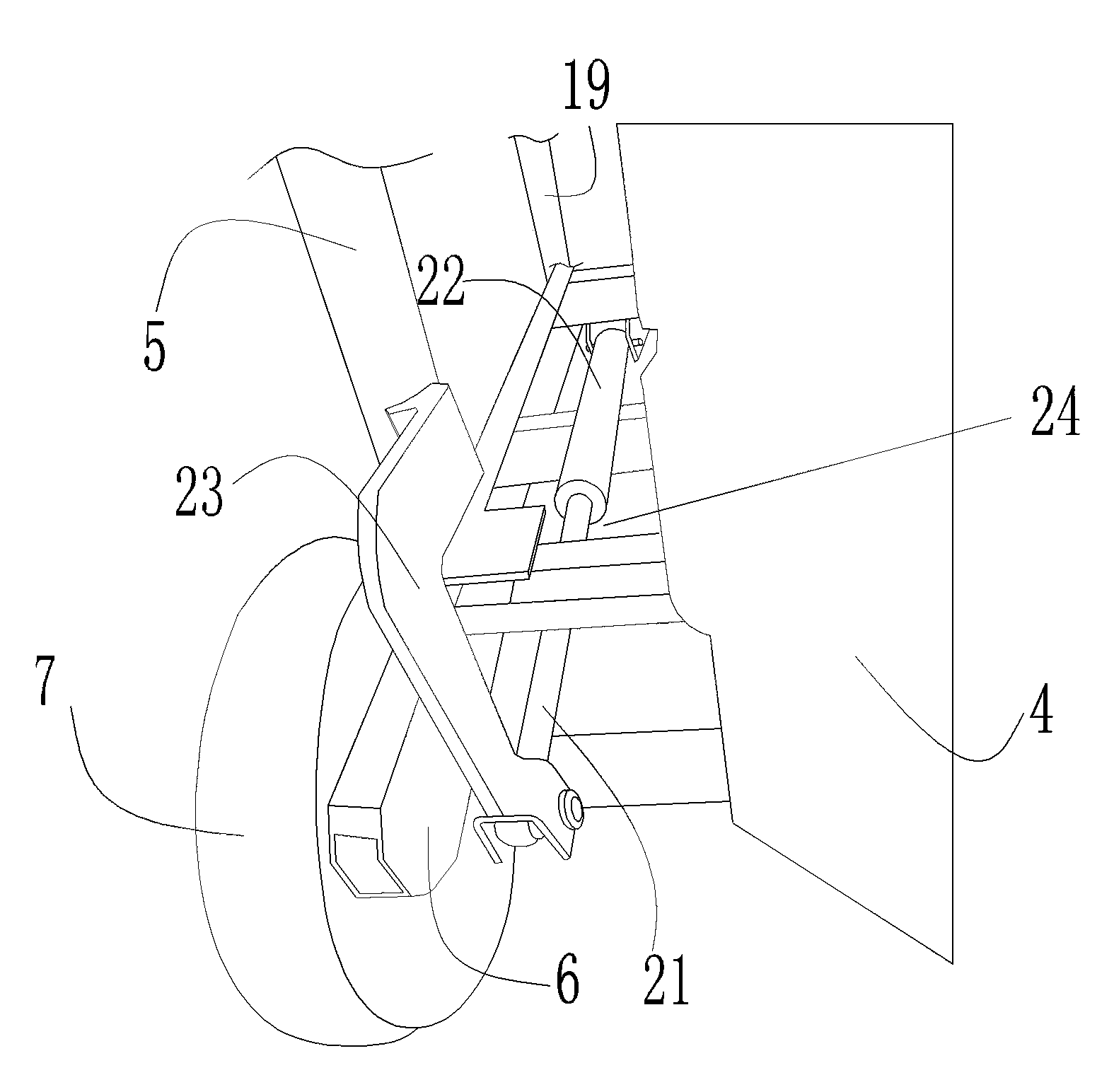

[0020] An example of a shallow hole drilling machine Figure 1~2 Shown: comprise the car body that has automatic driving function, and car body comprises chassis 6, and the front end of chassis 6 is equipped with internal combustion engine 20 and the transfer mechanism that the power input end is connected with the power output end of internal combustion engine 20, and the transfer mechanism is divided by the internal combustion engine. The transfer mechanism has a walking and drilling power output end, the chassis 6 is also provided with a front road wheel 25 and a rear road wheel 7, and the walking power output end of the transfer mechanism is connected to the front road wheel 25 through the road wheel transmission mechanism. Transmission connection, so as to realize the self-driving function of the chassis. The upper end of the chassis 6 is provided with a drilling assembly, a drilling tower 26 and a hydraulic drive mechanism. The drilling assembly includes a vertical shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com