Self-propelled cutter suction dredging device and driving method for water channel

A technology of a dredging device and a driving method, which is applied to mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc. The effect of adaptability, less energy consumption and less moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

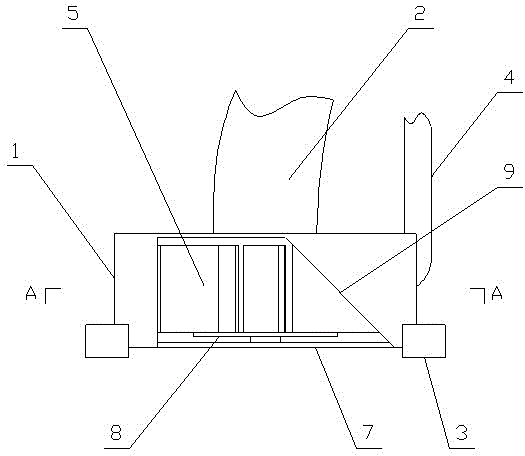

[0031] Example one, refer to the attached figure 1 , 2 , 3, 5.

[0032] A self-propelled cutter suction dredging device for water channels, which is characterized in that it comprises a volute 1, an impeller 5 is arranged in the volute, and a water inlet pipe 4 for pushing the impeller is arranged around the volute; a mud suction port is arranged in the center of the impeller, and The mud suction pipe port 2 in the center of one side of the shell is communicated, and a mud inlet is provided on the side of the periphery of the volute opposite to the water inlet pipe to expose the impeller to the volute.

[0033] The volute is in the shape of a flat truncated cone, the bottom 7 is in a closed state with the periphery of the volute, and the water inlet pipe 4 that pushes the impeller is smoothly and excessively connected along the tangent to the periphery of the volute 1;

[0034] The bottom 7 and the periphery of the volute are in a closed state, which means that the bottom of the volu...

Embodiment 2

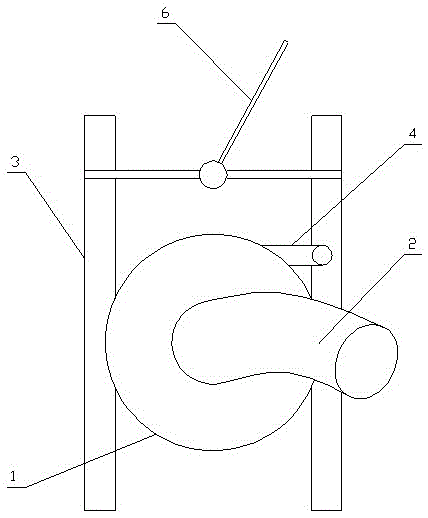

[0043] Example two, refer to the attached figure 1 , 2 , 3, 4.

[0044] A self-propelled cutter suction dredging device for water channels, which is characterized in that it comprises a volute 1, an impeller 5 is arranged in the volute, and a water inlet pipe 4 for pushing the impeller is arranged around the volute; a mud suction port is arranged in the center of the impeller, and The mud suction pipe port 2 in the center of one side of the shell is communicated, and a mud inlet is provided on the side of the periphery of the volute opposite to the water inlet pipe to expose the impeller to the volute.

[0045] The volute is in the shape of a basin, the bottom and the periphery of the volute are in a semi-closed state, and the water inlet pipe pushing the impeller is smoothly and excessively connected along the tangent line of the volute circle;

[0046] The bottom 7 and the periphery of the volute are in a semi-closed state, which means that the part of the bottom of the volute near...

Embodiment 3

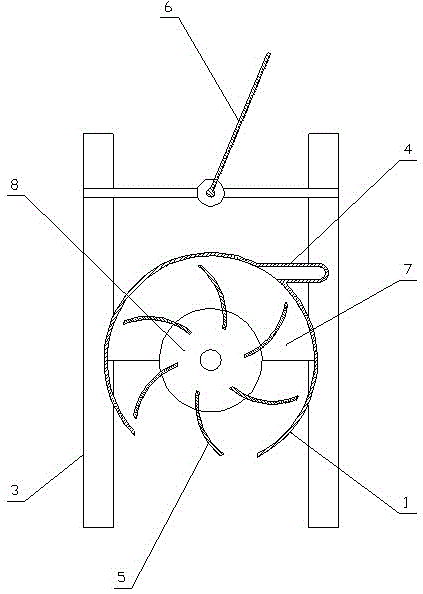

[0055] Example three, refer to the attached figure 1 , 2 , 3, 6.

[0056] A self-propelled canal dredging vessel includes a hull 10, power equipment and a mud conveying mechanism. It is characterized in that: a silt pump 13 and a water injection pump 11 are arranged on the dredging vessel, and the silt pump and the water injection pump are connected to a self-propelled cutter suction cleaning The silt suction device 16, said cutter suction dredging device includes a hydraulically driven dredged mud impeller 5 arranged in a flat volute 1, a water inlet pipe 4 pushing the impeller is arranged around the volute, and a mud suction port is formed in the center of the impeller, and The mud suction pipe port 2 in the middle of one side of the volute is connected, and a mud inlet is provided on the side opposite to the water inlet pipe 4 on the periphery of the volute. The mud inlet exposes the impeller to the volute, which is convenient for agitating the mud and the mud suction port in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com