self-propelled dredging vessel

A dredging ship, self-propelled technology, applied in the field of artificial canal dredging equipment, can solve the problems that are not suitable for artificial canal dredging operations, and achieve self-propelled adaptability, simple structure, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

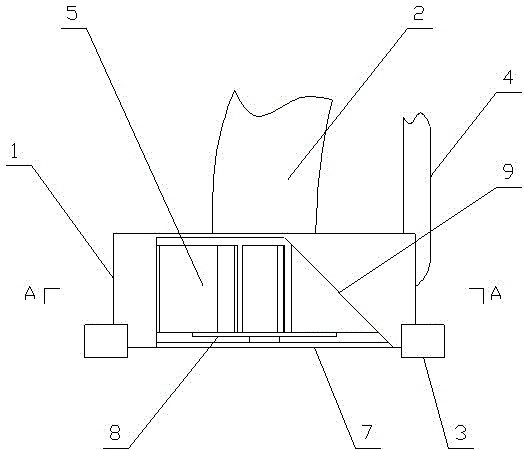

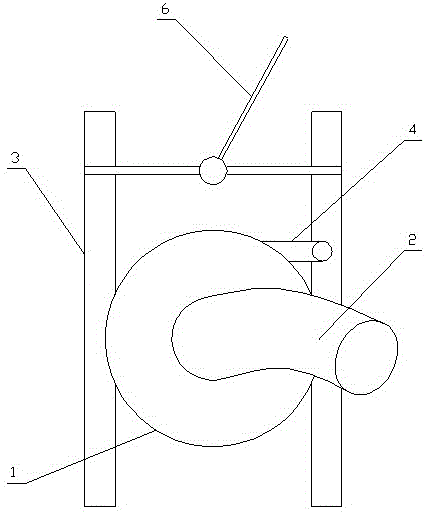

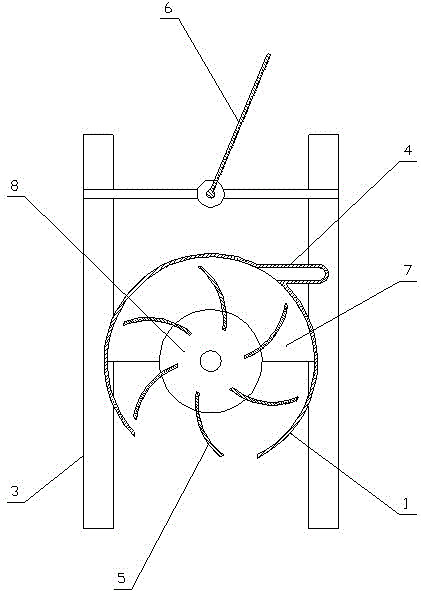

[0032]A self-propelled dredging ship for water channels, comprising a hull 10, power equipment, and a mud delivery mechanism, characterized in that a sludge pump 13 and a water injection pump 11 are arranged on the dredging ship, and the sludge pump and the water injection pump are connected to a self-propelled dredging cutter suction Head 16, the twisted suction head includes a horizontally placed volute 1 that is provided with a hydraulically propelled twisted mud impeller 5, the periphery of the volute is provided with a water inlet pipe 4 that pushes the impeller, and a mud suction port is formed in the center of the impeller, which is integrated with the volute. The mud suction nozzle 2 in the middle of the side is connected, and the mud inlet is set on the side opposite to the water inlet pipe 4 around the volute. The suction head connects the steel cable with the crane lifting arm 15 and forms a fixed connection with the hull.

[0033] The twisted suction head includes ...

Embodiment 2

[0045] A self-propelled dredging ship for water channels, comprising a hull 10, power equipment, and a mud delivery mechanism, characterized in that: a sludge pump 13 and a water injection pump 11 are arranged on the dredging ship, and the sludge pump and the water injection pump are connected to a self-propelled dredging tank via a pipeline. Wringer suction head 16, said twister suction head includes hydraulically propelled mud-cutter impeller 5 arranged in horizontal volute 1, the water inlet pipe 4 that pushes the impeller is arranged on the periphery of the volute and is connected with water injection pump 11, and is formed in the center of the impeller. The mud suction port is connected with the mud suction nozzle in the middle of one side of the volute, and the mud suction nozzle is connected with the sludge pump 13. A mud inlet is provided on the side opposite to the water inlet pipe around the volute, and the mud inlet exposes the impeller. The volute is convenient to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com