Linear density test method of withdrawing yarn of woven fabric for linear density under unknown name of yarn

A linear density and woven fabric technology, applied in the field of textile testing, can solve problems such as yarn linear density cannot be measured, and achieve the effects of short inspection cycle, simple inspection operation and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

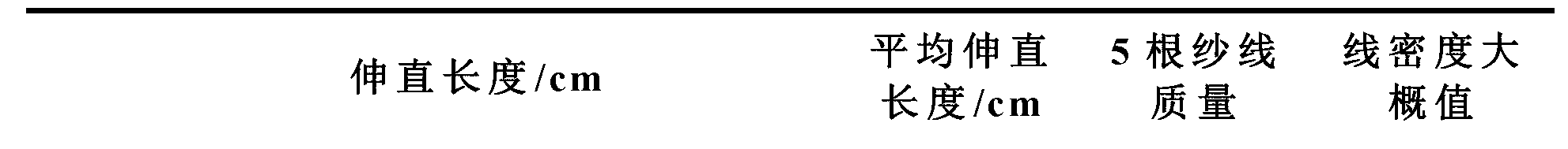

[0038] Example Blind Fabric Test Example

[0039] A piece of woven fabric A with unknown nominal linear density (cotton-type yarn, without coating and other non-fibrous substances, single yarn, actual specification is 21s×21s, take this sample as a blind fabric test, and compare the test results with the specifications ), it is required to test the yarn linear density, the test procedure and results are as follows.

[0040] 1 Sample preparation

[0041] Since the samples do not contain non-fibrous substances such as coatings, no pretreatment according to ISO 1833-1 is required. Place the sample in a constant temperature and humidity chamber and adjust the humidity to the equilibrium state specified in GB / T 6529.

[0042] 2 Approximate value of test yarn linear density

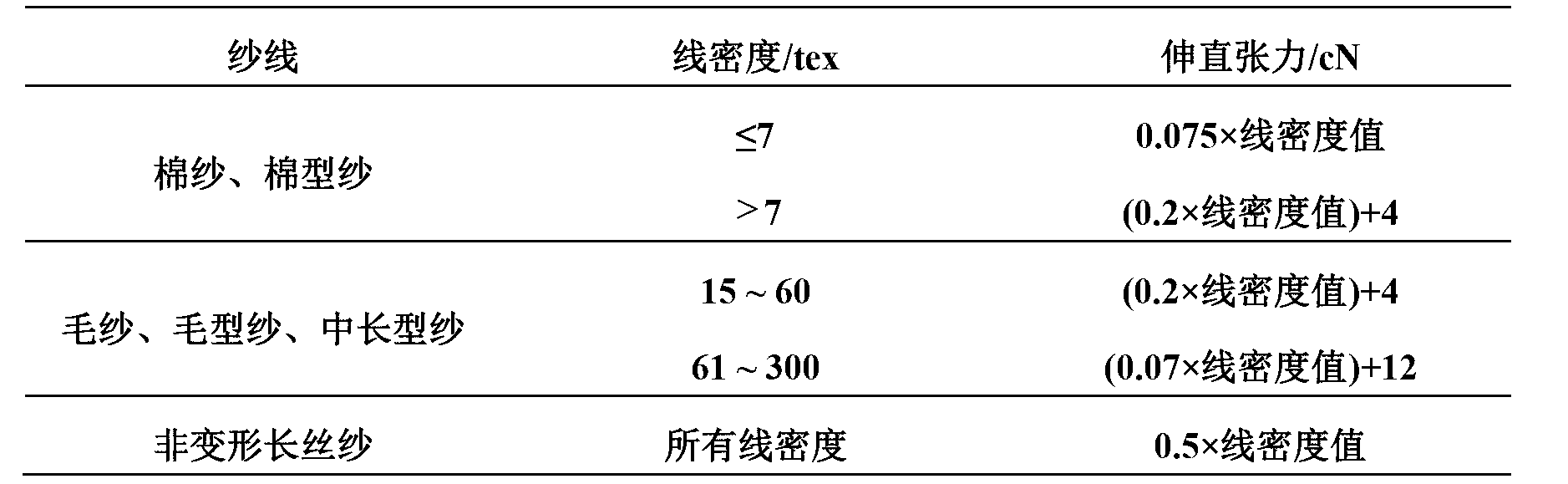

[0043] The two ends of the yarn removed from the fabric are respectively clamped into the two clamps of the yarn length tester, and the two clamps are separated without straightening tension until the curl o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com