Assembly workshop intelligent control system and control method

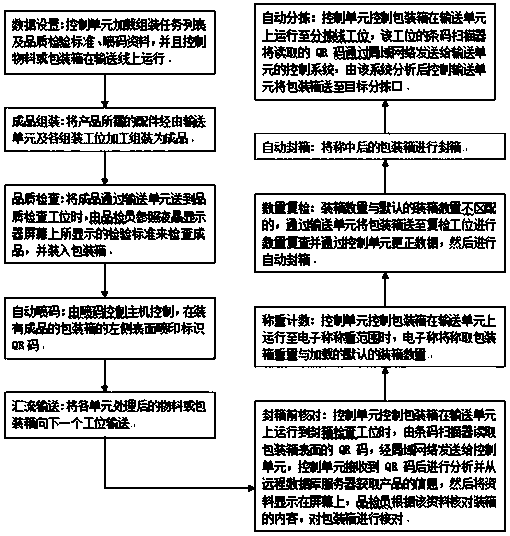

A technology of intelligent control system and assembly workshop, applied in general control system, control/regulation system, program control, etc., can solve the problems of waste of paper, waste of labor, chaos and disorder, etc., to prevent untimely printing and waste of resources , The effect of simplifying the inspection operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

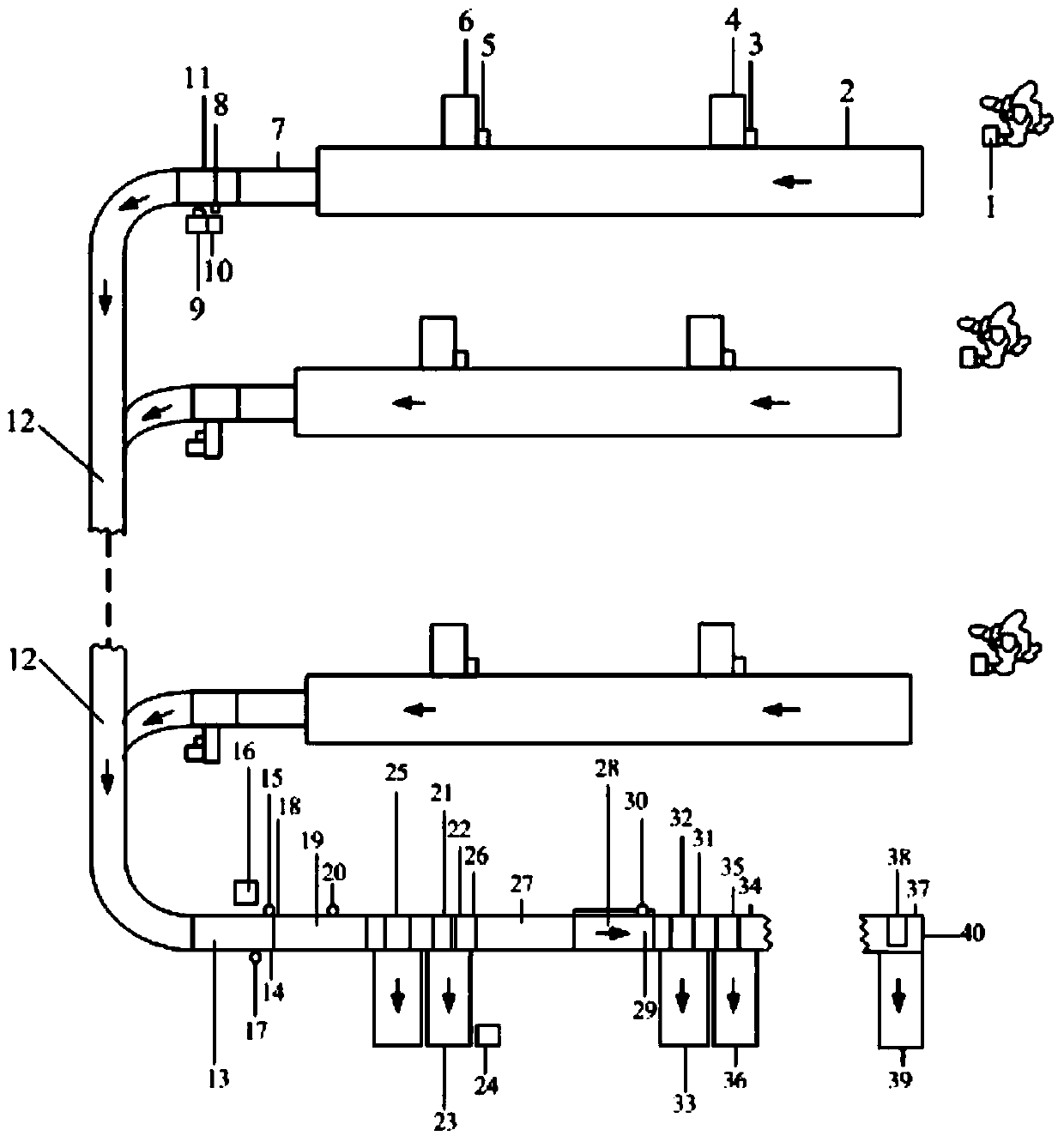

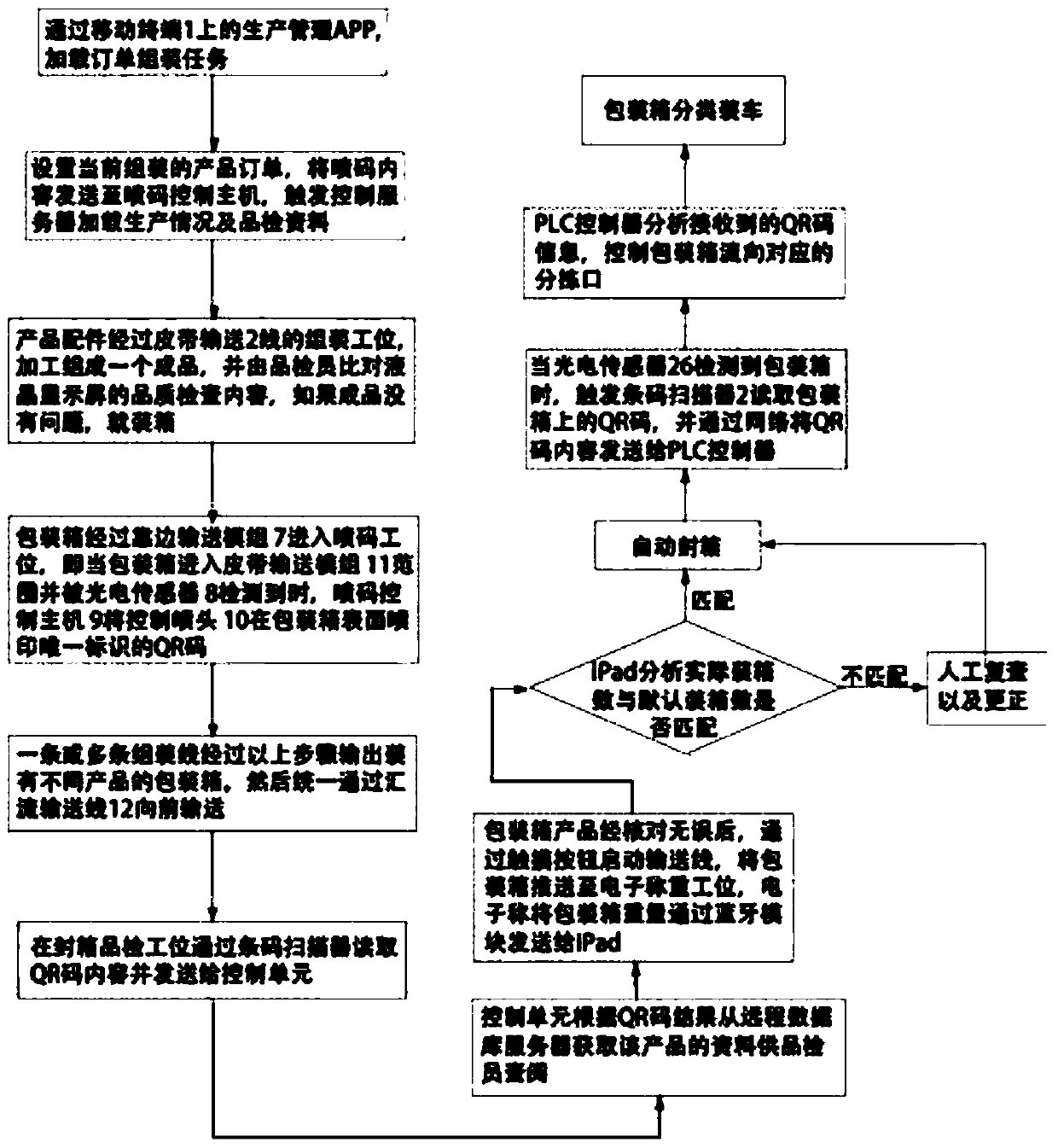

[0032] In the control system implementing the control method of the present invention, the control unit includes: mobile terminal 1, control server 3, control server 5, code spraying control host 9, mobile terminal 16, mobile terminal 24 and PLC automatic control module; conveying unit includes: belt Conveyor line 2, side transport module 7, belt transport module 11, confluence transport line 12, side transport module 13, re-inspection transport line 23, side transport module 28, sorting transport line 40.

[0033] The PLC automatic control module of the present invention also includes: liquid crystal television 4, liquid crystal display screen 6, photoelectric sensor 8, nozzle 10, photoelectric sensor 14, barcode scanner 15, touch button 17, photoelectric sensor 18, electronic scale 19, bluetooth communication module 20. Pneumatic push arm 21, photoelectric sensor 22, transfer machine 25, photoelectric sensor 26, automatic box sealing machine 27, photoelectric sensor 29, barco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com