Positioning alignment apparatus of double-side driving workpiece platform without being connected by cross beam

A technology of double-sided driving and alignment devices, which is applied in the photo-plate-making process exposure device, the photo-plate-making process of the pattern surface, optics, etc., can solve the problems of time-consuming, reduce work efficiency, damage the load structure, etc., and achieve positioning and Alignment problems, improve work efficiency, simple and reliable effect of positioning alignment device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings to the principle, structure and working process of the present invention.

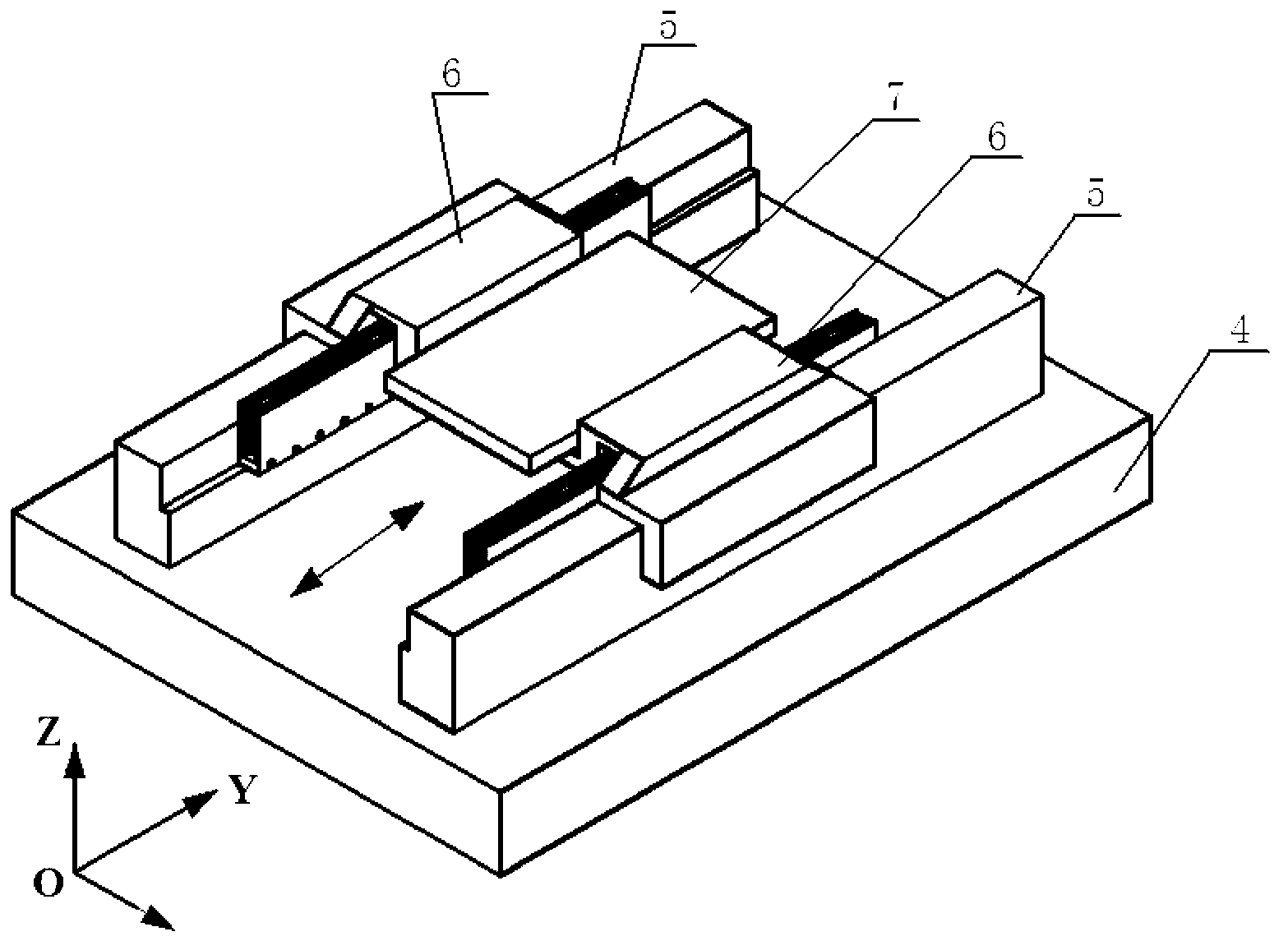

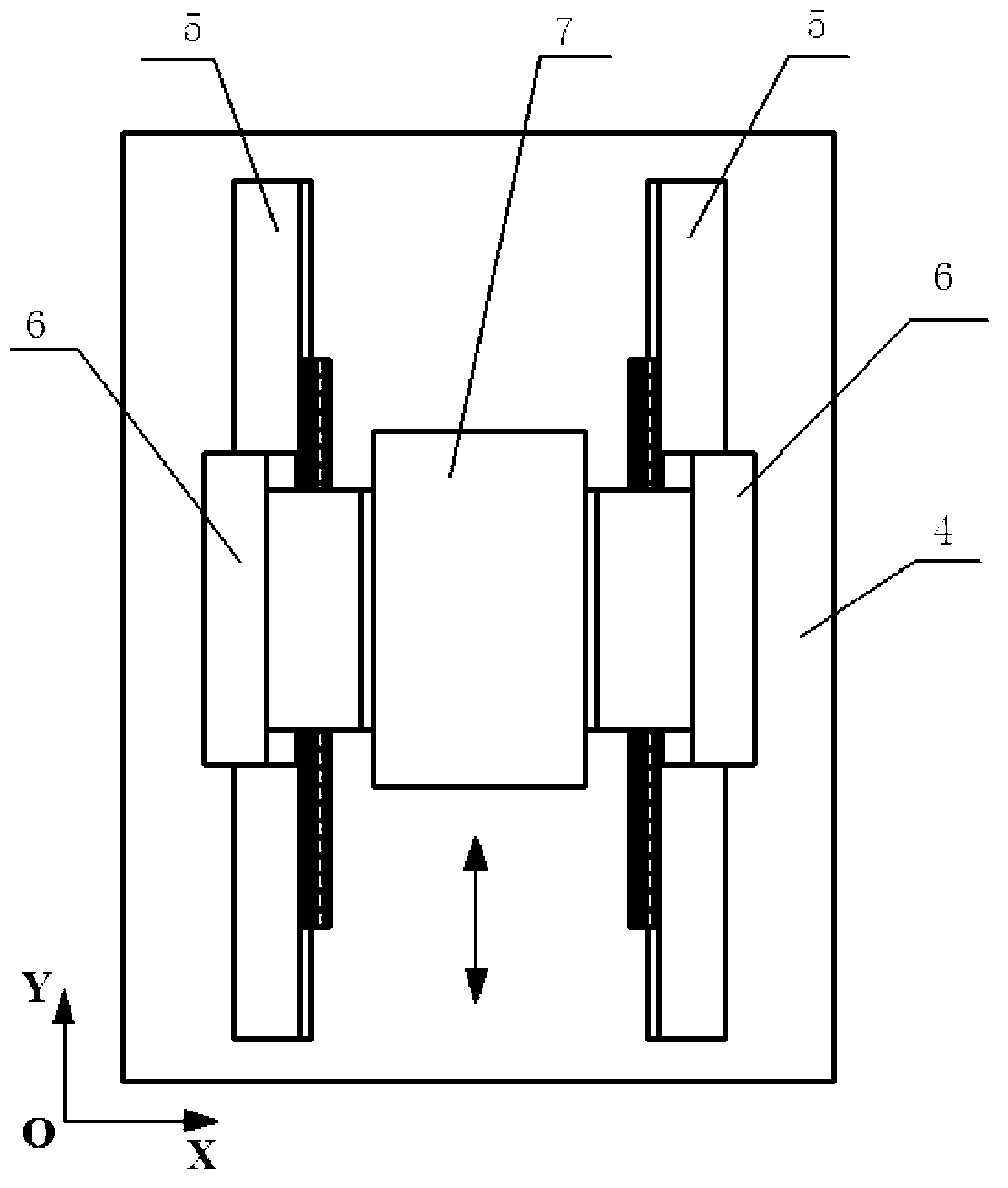

[0022] figure 1 It is a structural schematic diagram (axonometric view) of a double-sided driving table without beam connection, figure 2 for its top view. The whole structure includes two workpiece tables 6 with the same structure, guide rails 5 , load 7 and base 4 . The workpiece table 6 is supported and guided by the air bearing, and can move along the Y-axis on the guide rail 5. The left and right workpiece tables 6 are symmetrically arranged on the guide rail 5 along the X-axis direction, and the guide rail 5 is fixed on the base 4. The left and right workpiece tables There is no mechanical connection between them, and there is no mechanical connection between the load 7 and the left and right workpiece tables.

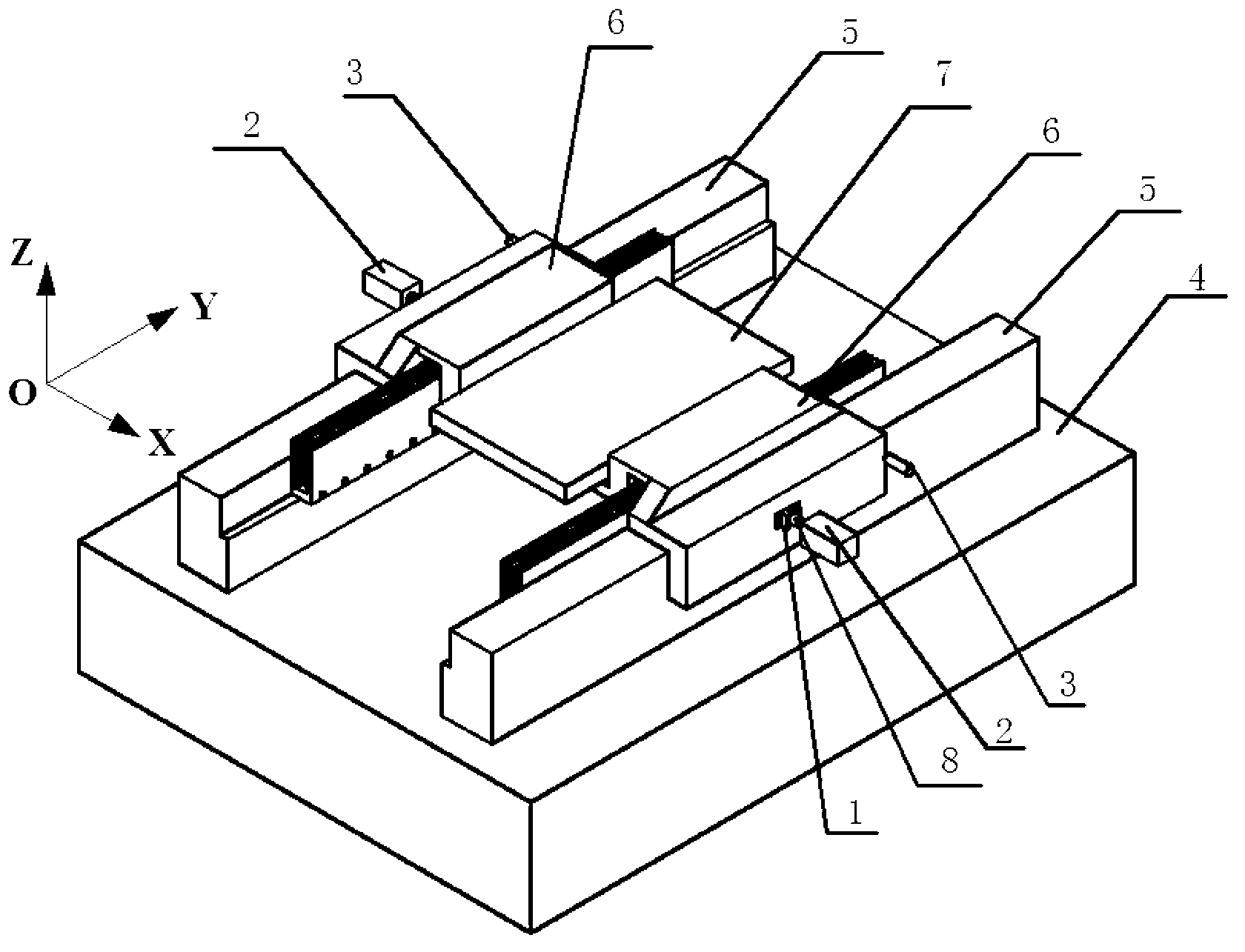

[0023] image 3 It is a schematic diagram (axonometric drawing) of the prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com