Offshore composite cable with low-temperature resistance, salt spray resistance and high strength

A comprehensive cable and high-strength technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems that cannot meet the requirements of low temperature resistance and salt spray, and achieve the effects of good insulation, easy wrapping, and improved transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

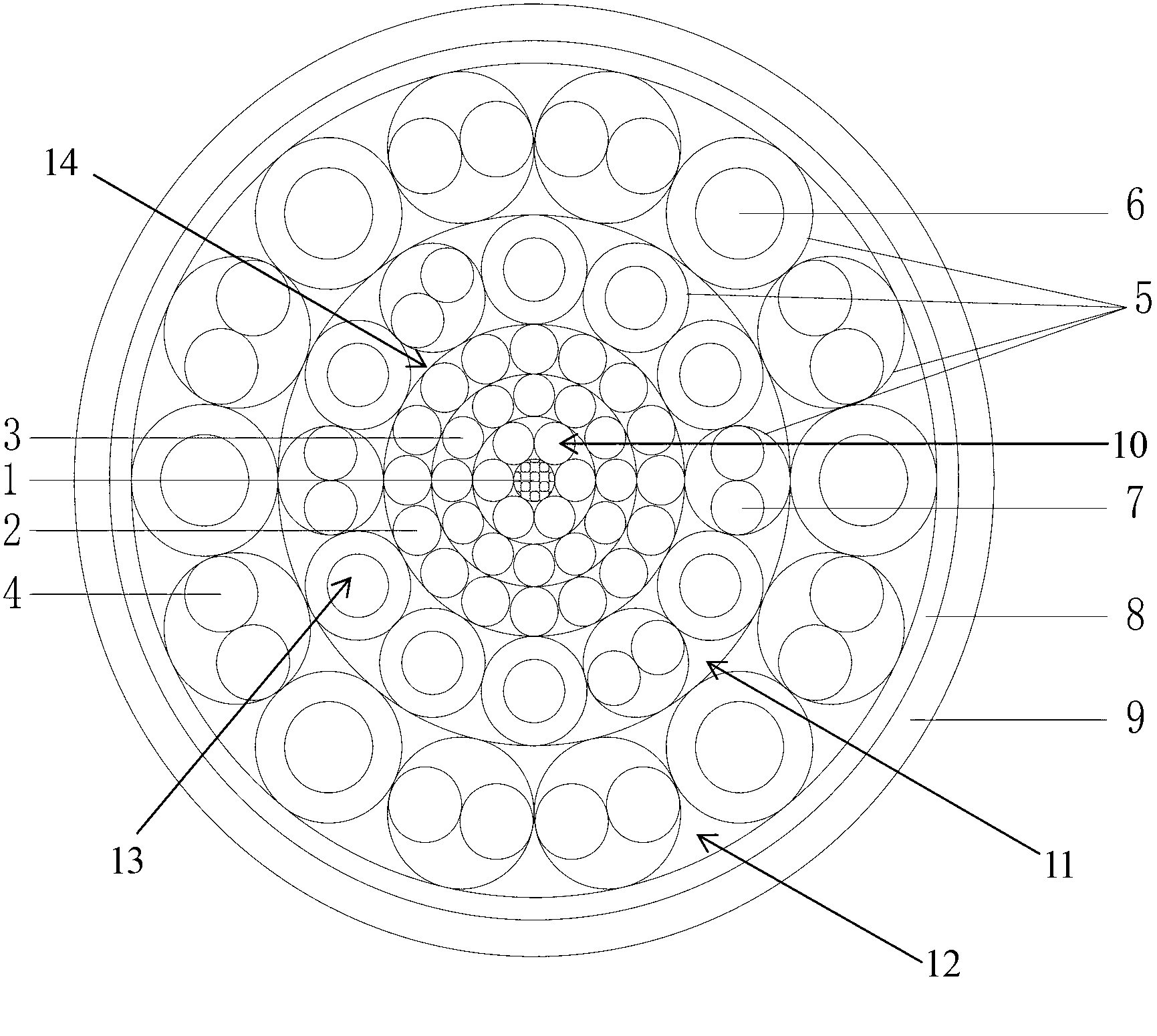

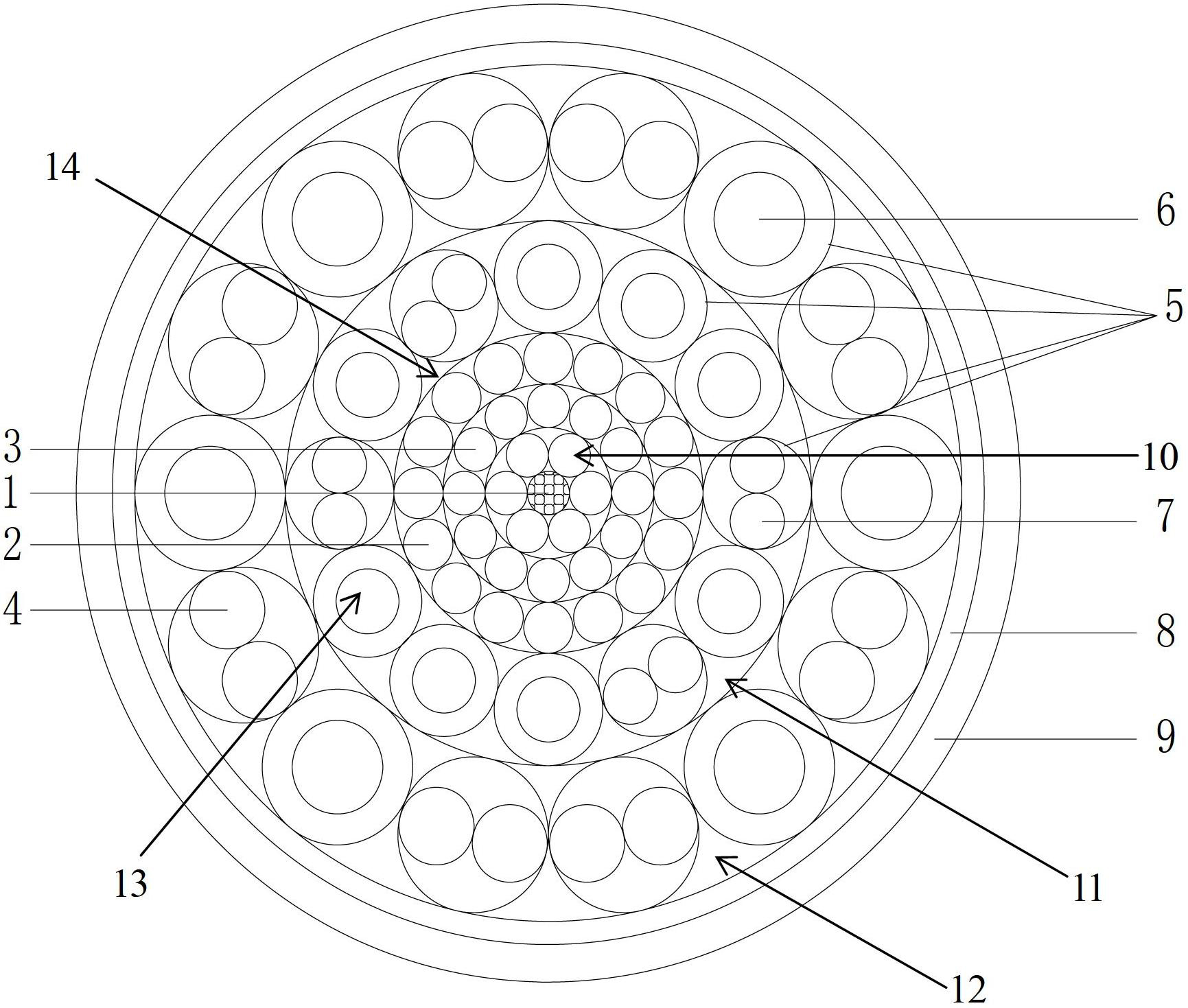

[0028] like figure 1 As shown, the low temperature resistant, salt spray, high strength marine integrated cable of the present invention mainly includes: non-hygroscopic filling layer 1, third layer of insulated wire core 2, second layer of insulated wire core 3, diameter 1.5mm 2 Twisted pair shielded insulated wire core 4, tinned copper braided shielding layer 5, diameter 3.0mm 2 Shielded insulated wire core 6, diameter 0.35mm 2 Twisted pair shielded insulated wire core 7, flame retardant glass cloth with cushion layer 8, flame retardant PVC (polyvinyl chloride) elastomer sheath 9, first layer of insulated wire core 10, fourth layer of insulated wire core 11, fifth layer Insulated wire core 12, diameter 0.75mm 2 Shielded insulated wire core 13, etc., wherein:

[0029] The insulated wire cores are divided into the first to fifth layers of insulated wire cores arranged from the inside to the outside: the first layer of insulated wire cores 10, the second layer of insulated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com