Annular parallel gap lightning protection device for overhead circuit insulator string

A technology of insulator strings and overhead lines, applied in the field of lightning protection devices, to achieve the effect of standardization of design, uniform end electric field, and improvement of electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

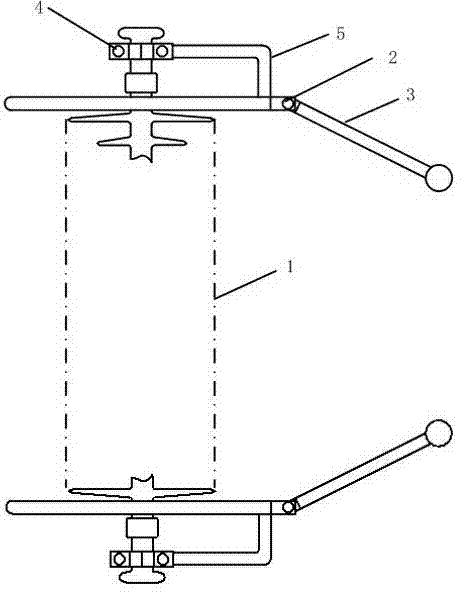

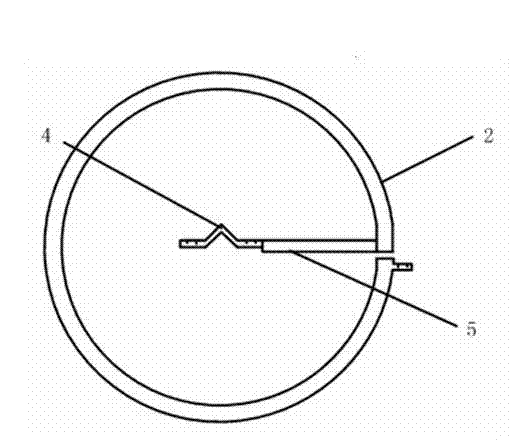

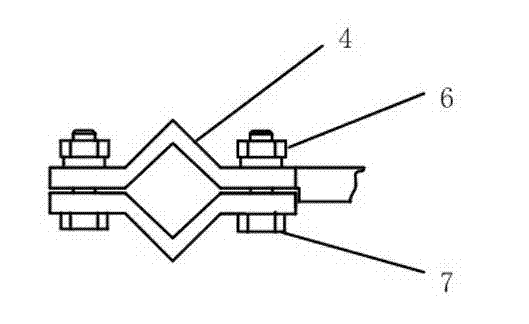

[0031] Such as Figure 1~3 As shown, a ring-shaped parallel gap lightning protection device for 110kV overhead line insulator strings is to connect a pair of metal electrodes in parallel at both ends of the insulator string 1 of the overhead line. It is characterized in that: one metal electrode in the pair of metal electrodes is mainly composed of a ring electrode 2, a rod-shaped electrode 3, an "L"-shaped connecting rod 5 and a metal clamp 4 and the like.

[0032] The ring electrode 2, the rod-shaped electrode 3 and the "L"-shaped connecting rod 5 are all carbon steel metal rods with a diameter of 15mm.

[0033] The ring electrode 2 is an open ring of a metal rod with an inner diameter of 300mm. Weld one of the "L"-shaped connecting rods 5 on one end face of the opening of the ring electrode 2 opening, so that the ring-shaped parallel electrode is fixedly connected to the end of the metal piece at one end of the overhead line insulator string The ring electrode 2 with an o...

Embodiment 2

[0038] A ring-shaped parallel gap lightning protection device for 220kV overhead line insulator strings, same as embodiment 1, wherein:

[0039] The ring electrode 2, the rod electrode 3 and the connecting rod 5 are all carbon steel metal rods with a diameter of 18 mm. The ring electrode 2 is a metal rod with an inner diameter of 350 mm. The length of the electrode 3 is 300mm, the spherical diameter of the rod-shaped electrode 3 is 45mm, the vertical rod length of the "L"-shaped connecting rod 5 is 30mm, and the horizontal rod length is 350mm.

[0040] The distance between the spherical ends of the rod-shaped electrodes 3 in the parallel gap is 1744mm.

Embodiment 3

[0042] A ring-shaped parallel gap lightning protection device for 220kV overhead line insulator strings, same as embodiment 1, wherein:

[0043] The ring electrode 2, the rod electrode 3 and the connecting rod 5 are all carbon steel metal rods with a diameter of 20 mm. The ring electrode 2 is a metal rod with an inner diameter of 400 mm. The length of the electrode 3 is 400mm, the spherical diameter of the rod-shaped electrode 3 is 50mm, the vertical rod length of the "L"-shaped connecting rod 5 is 50mm, and the horizontal rod length is 400mm.

[0044] The distance between the spherical ends of the rod-shaped electrodes 3 in the parallel gap is 3780mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com