High voltage pulse electric field sterilization common-field treatment chamber with adjustable electrode distance

A technology of high-voltage pulsed electric field and electrode spacing, which is applied in food science, food preservation, application, etc., can solve the problems that restrict the development and application of high-voltage pulsed electric field sterilization technology, small square wave pulse width and fast pulse frequency, etc. Development and application, uniform distribution of electric field intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

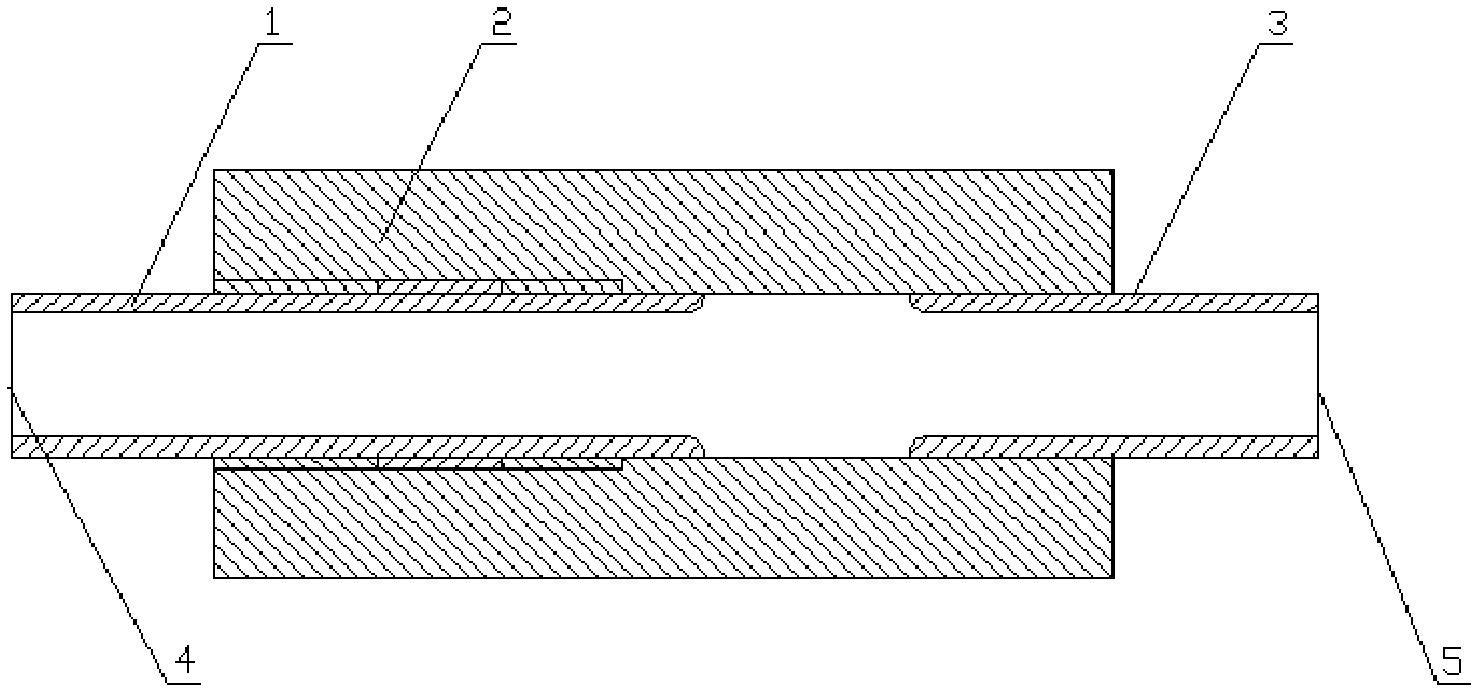

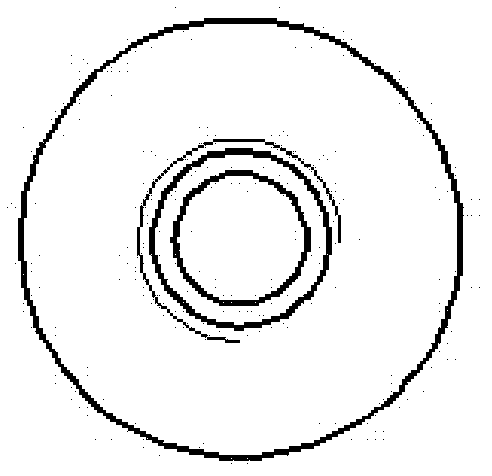

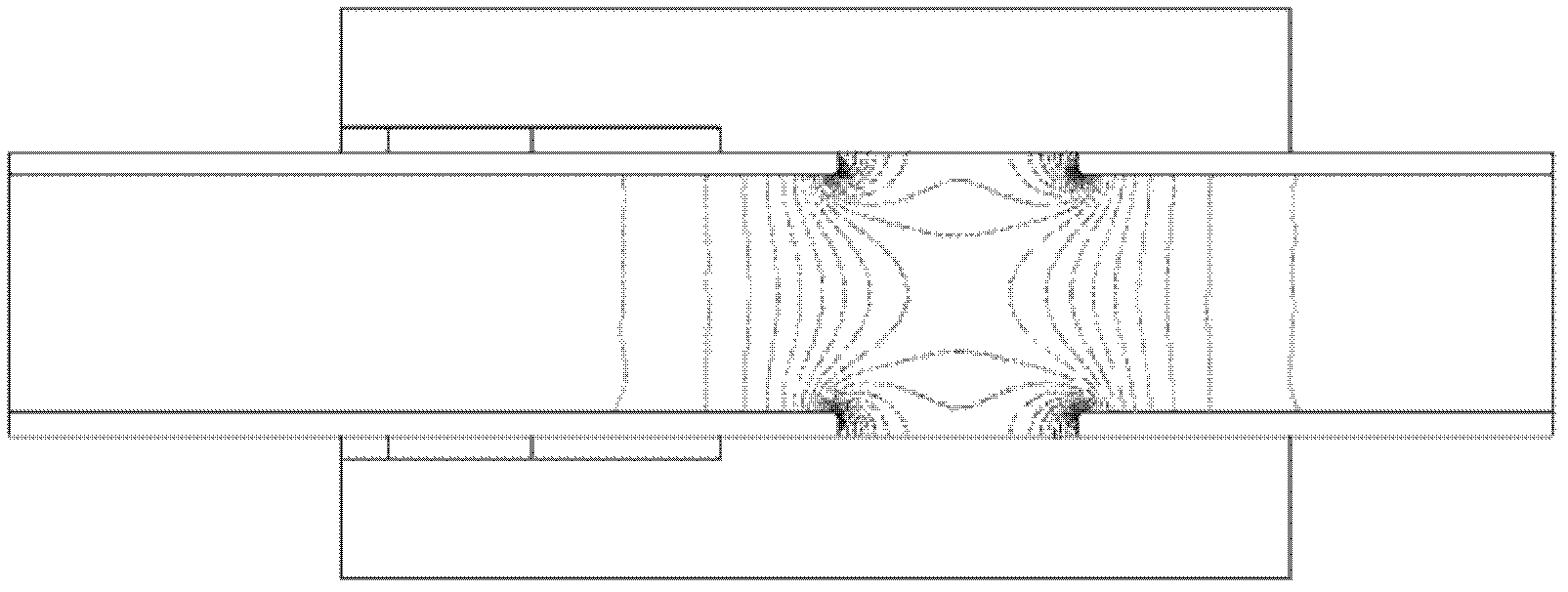

[0017] like figure 1 and figure 2 As shown, the high-voltage pulse electric field sterilization co-field treatment chamber with adjustable electrode spacing provided by the present invention is composed of a metal hollow tubular ground electrode 1, an insulator isolation tube 2, a metal hollow tubular high-voltage electrode 3, a material inlet 4, and a material outlet 5. . The insulator isolation tube 2 is located between the metal hollow tubular ground electrode 1 and the metal hollow tubular high voltage electrode 3 to form a processing chamber cavity, the metal hollow tubular ground electrode is connected to the feed inlet, and the metal hollow tubular high voltage electrode is connected to the discharge port. The metal hollow tubular grounding electrode 1 and the insulator isolation tube 2 are threaded, and the electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com