Apparatus for installation of ultraviolet system for ballast water treatment in explosive atmosphere of shipboard pump rooms and offshore platforms

An explosive gas, offshore platform technology, applied in the field of UV system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

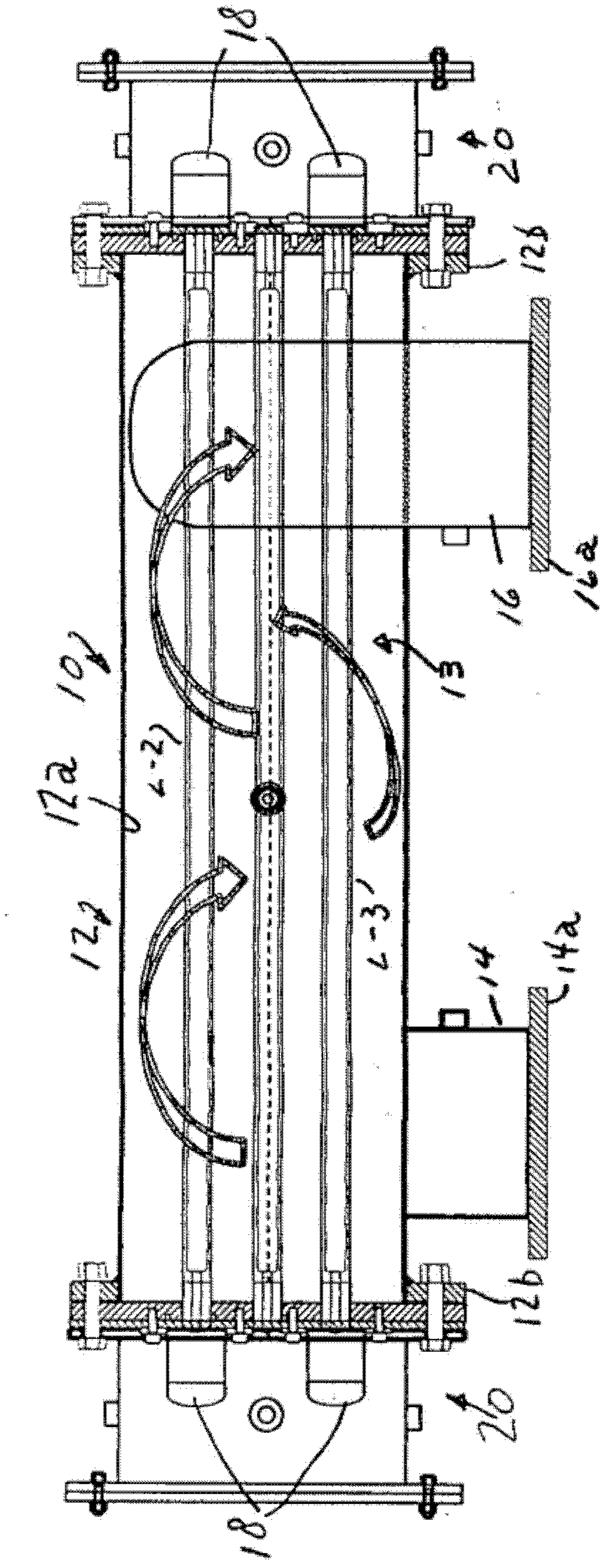

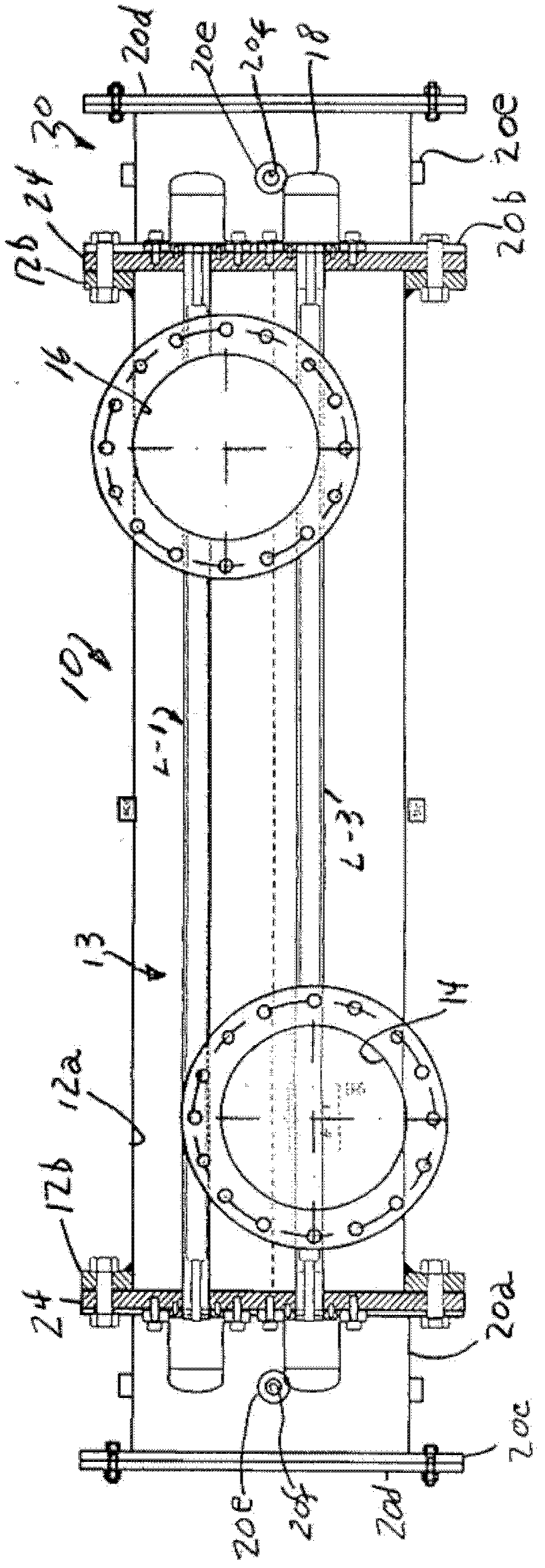

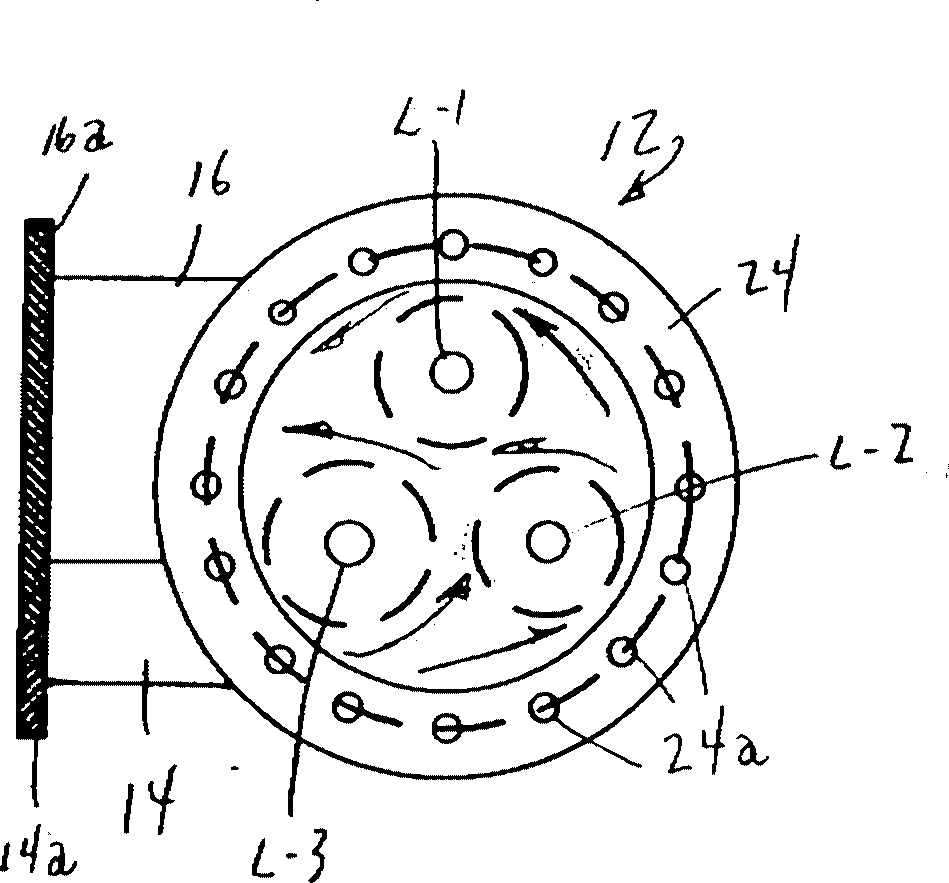

[0028] With reference to the accompanying drawings, the present invention relates to a UV water treatment system 10 comprising a reactor 12, an inlet line 14 and an outlet line 16 for supplying water through the reactor, a plurality of UV treatment lamps L-1, L-2 and L-3, the cover 18 at the opposite end of each UV lamp, the explosion-proof enclosure 20 at each end of the reactor, and the control and operating components 22 ( Figure 12 ).

[0029] The reactor comprises a main cylindrical shell 12a, preferably made of titanium, with a diameter ranging from 300mm to 600mm (depending on the desired flow capacity of the device). An annular flange 12b is welded to the end of the main body shell. The total length of the reactor from flange to flange is 1500mm.

[0030] An inlet pipe 14 is welded at 90° at the periphery to the surface of the lower part of the shell, the size of the inlet pipe 14 corresponds to the flow rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com