Gypsum board

A gypsum board and gypsum technology, applied in the field of gypsum board, can solve the problems of high pH, low compressive strength of gypsum board strength, long time-consuming slurry hardening, etc., and achieve the effect of preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

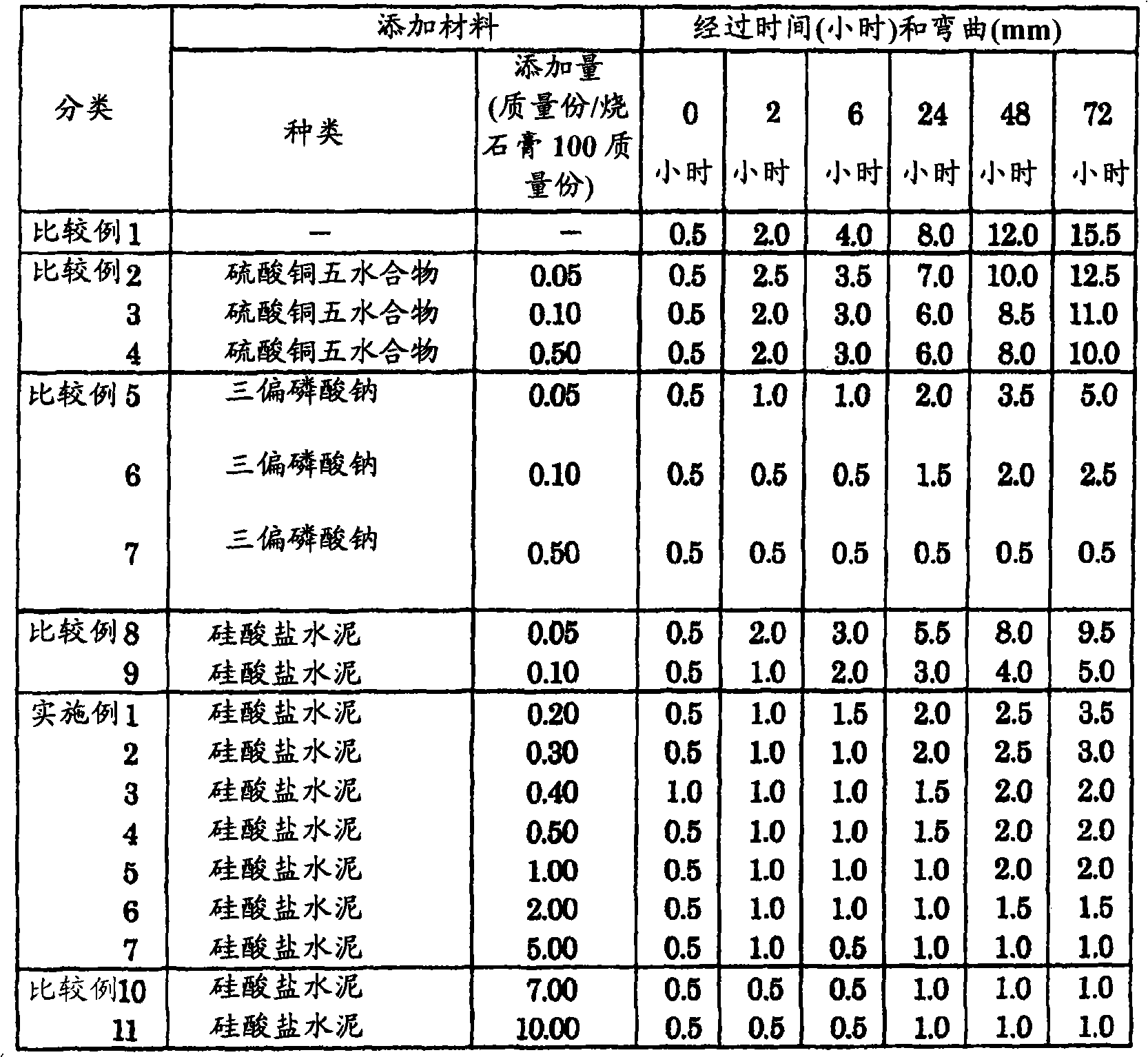

Embodiment 8~14 and comparative example 13~15

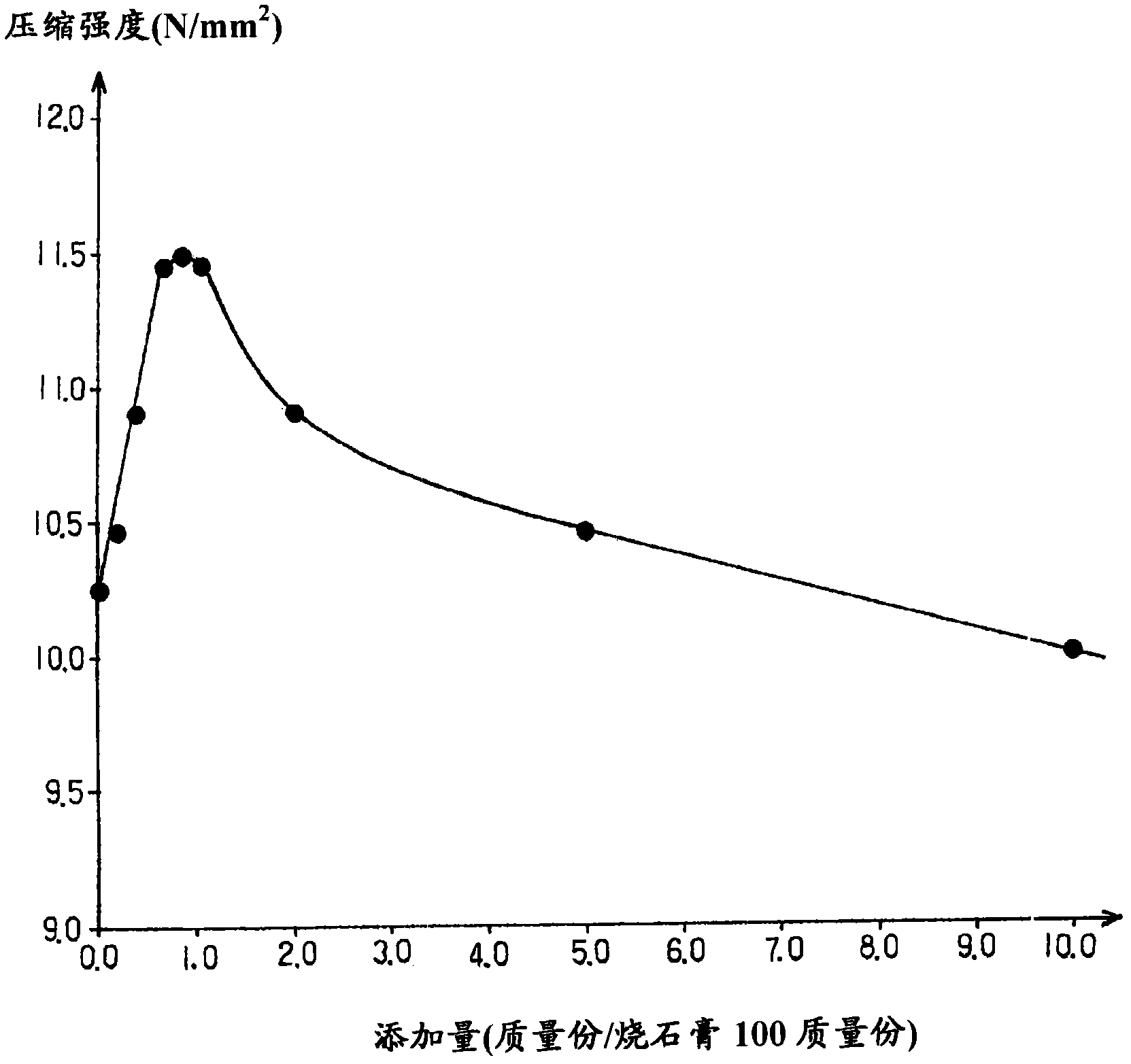

[0044] Except for using 500 g of ordinary Portland cement mixed with calcined gypsum in an amount described in Table 1 instead of 500 g of calcined gypsum, it was carried out in the same manner as in Comparative Example 12. After preparing a slurry and obtaining a gypsum board, Determine the compressive strength. The results are shown in Table 2 and figure 1 .

[0045] Table 2

[0046]

[0047] Table 2,

[0048] Addition amount: add the mass parts of ordinary Portland cement per 100 mass parts of calcined gypsum

[0049] From Table 2 and figure 1 The results of the results can also be clear, although per 100 parts by mass of calcined gypsum adding the mass parts of ordinary portland cement in the range of 0.20 ~ 5.0, compared with the case without adding ordinary portland cement (comparative example 12), the compressive strength At about the same level or more, but when the mass parts of ordinary portland cement are added more than this, for example, when it is 10.0 or...

Embodiment 15 and comparative example 17~19

[0054] Except for using calcined gypsum mixed with ordinary Portland cement in an amount described in Table 1 instead of calcined gypsum, the same procedure was carried out as in Comparative Example 16 to prepare a slurry and measure the hardening when the hardened body was obtained. Time (minutes to end) vs. pH. The results are summarized in Table 3.

[0055] table 3

[0056]

[0057] Table 3,

[0058] Addition amount: add the mass parts of ordinary Portland cement per 100 mass parts of calcined gypsum

[0059] It is also clear from the results in Table 3 that when the mass parts of ordinary Portland cement added per 100 mass parts of calcined gypsum is increased to 20-30, compared with the case of not adding ordinary Portland cement (Comparative Example 16), , the hardening time becomes longer, and the pH becomes significantly higher.

[0060] Test Category 4

Embodiment 16

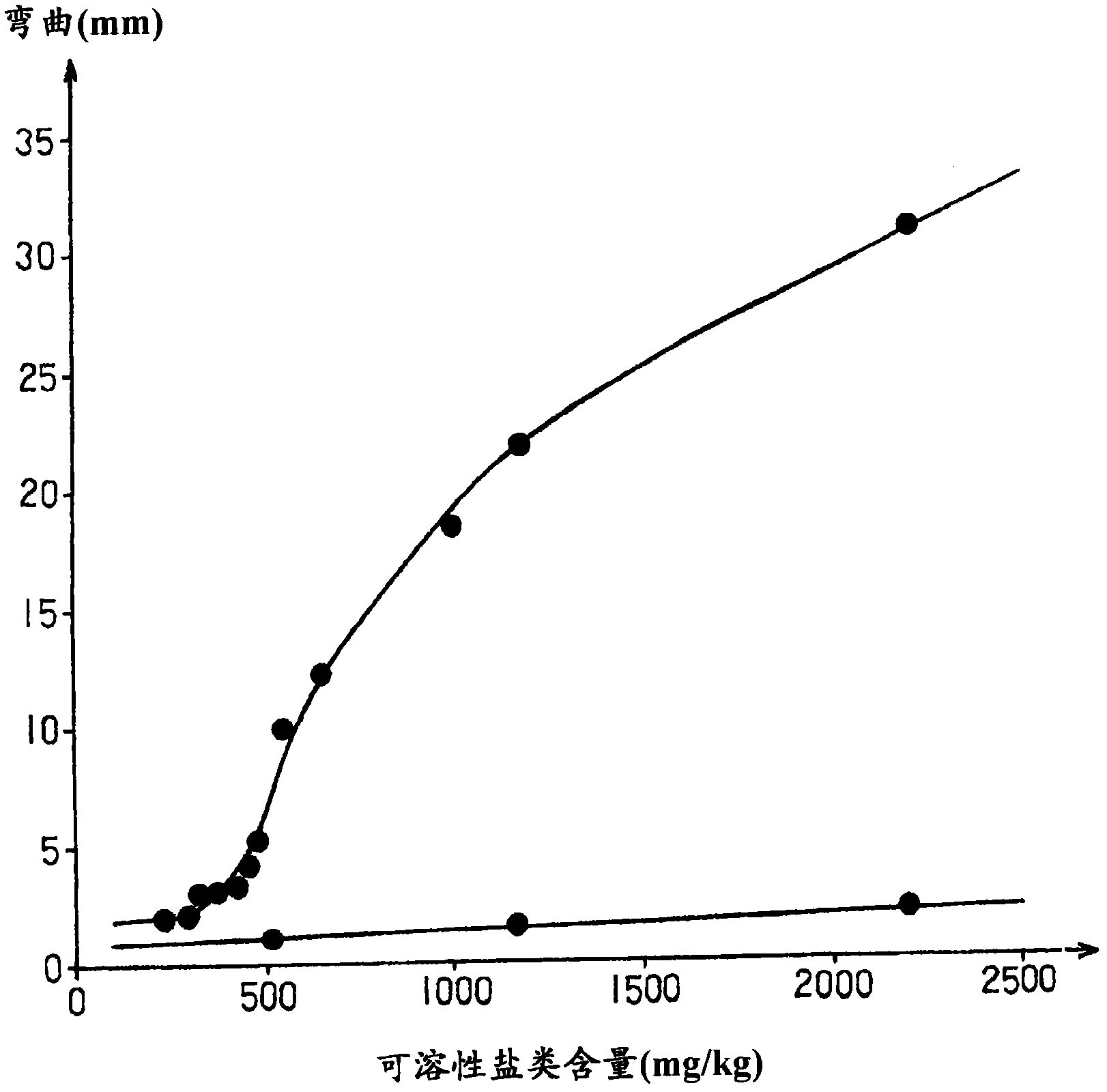

[0066] In the same manner as in Comparative Example 27, except that ordinary Portland cement was mixed in the amount described in Table 4 instead of calcined gypsum, after the slurry was prepared to obtain a gypsum board, a test piece was cut out and measured. Bend after 48 hours. The results are summarized in Table 4 and figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com