Steel pipe pile

A technology of steel pipe piles and steel pipes, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problem that the reduction of foundation resistance cannot be fully realized, the improvement of constructability does not play a role, and the foundation cannot be fully realized. The reduction of resistance and other issues can achieve the effect of realizing construction cost, reducing construction load and realizing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In this specification and drawings, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted.

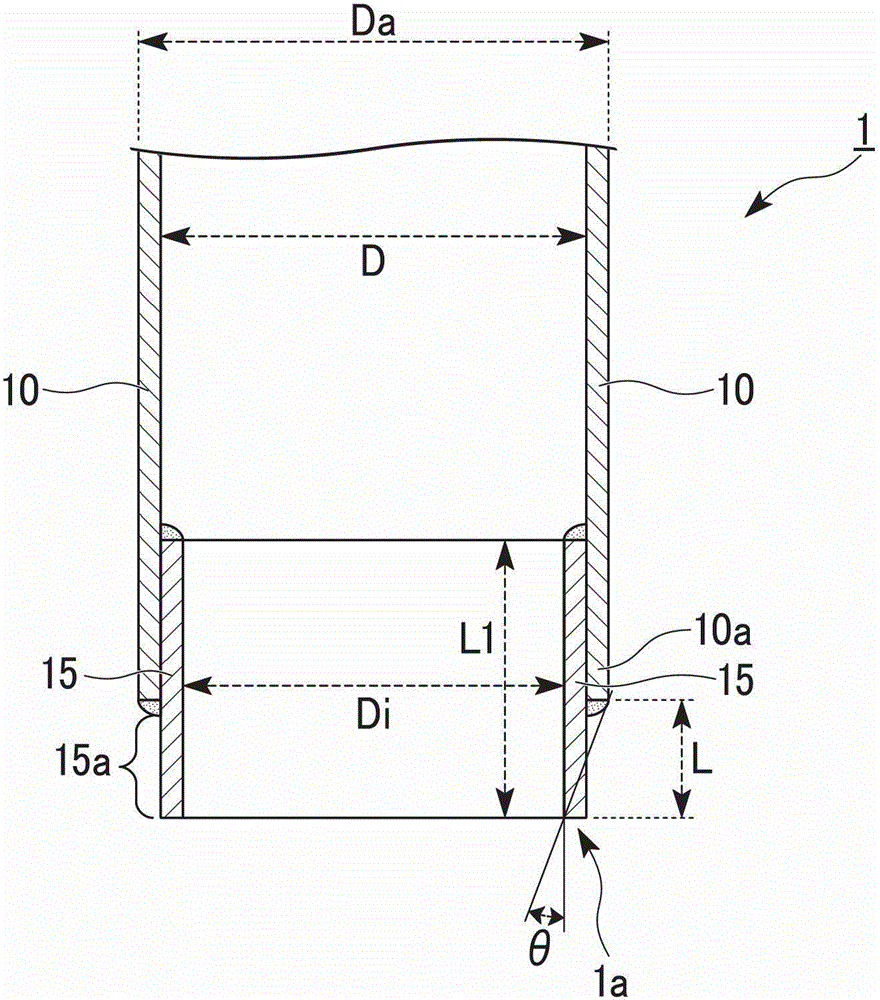

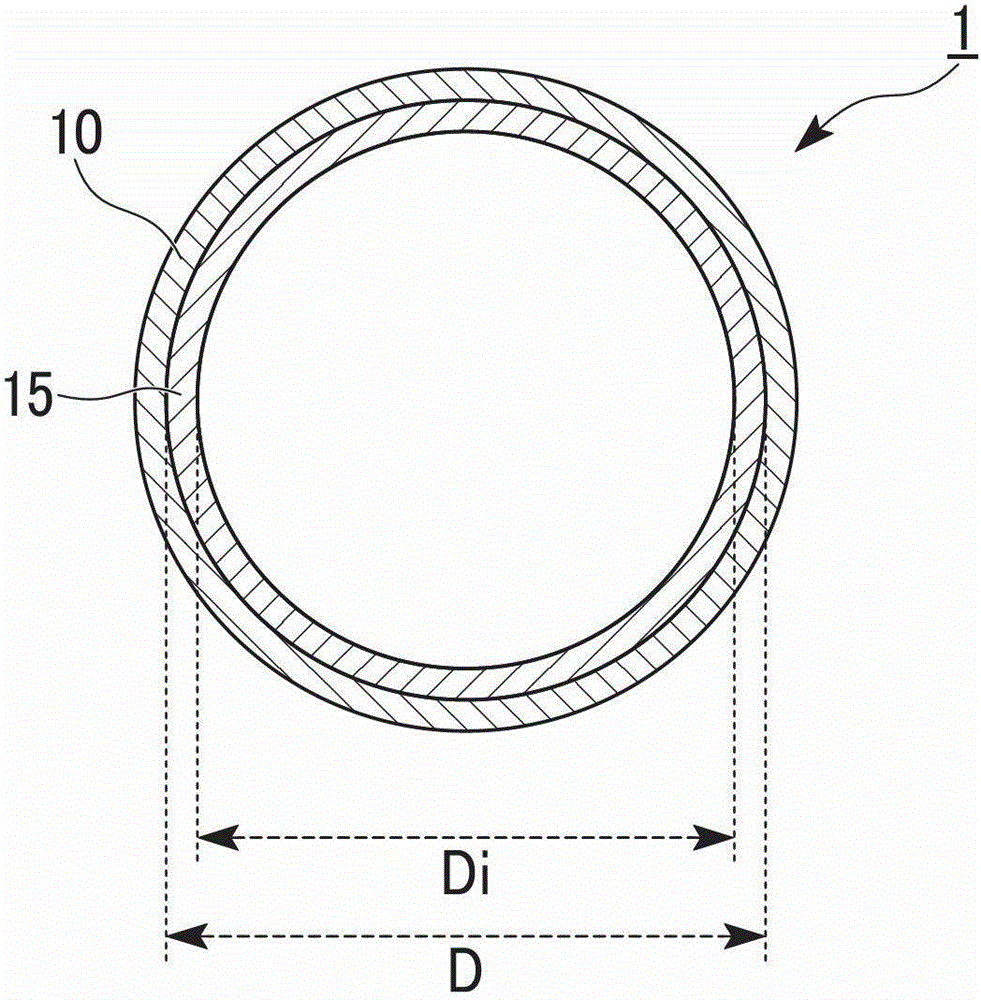

[0055] Figure 1A It is a side sectional view of the steel pipe pile 1 according to the first embodiment of the present invention, Figure 1B It is a plan view of the steel pipe pile 1. like Figure 1A As shown, the steel pipe pile 1 is equipped with the cylindrical reference steel pipe 10 which has a hollow inside, and the inner peripheral steel pipe 15 which has a hollow inside. The inner peripheral steel pipe 15 is provided on the inner surface of the front end portion 10 a of the reference steel pipe 10 , and is disposed so as to protrude from the front end portion 10 a of the reference steel pipe 10 . The inner peripheral steel pipe 15 is fixedly connected to the refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com