Hydraulic system with servo pump and bypass valve

A hydraulic system and servo pump technology, applied in the direction of servo motors, servo meter circuits, fluid pressure actuators, etc., can solve problems such as high pressure peaks, hydraulic system damage, problems, etc., to achieve simple output pressure and avoid pressure peaks , The effect of saving hydraulic pressure medium pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

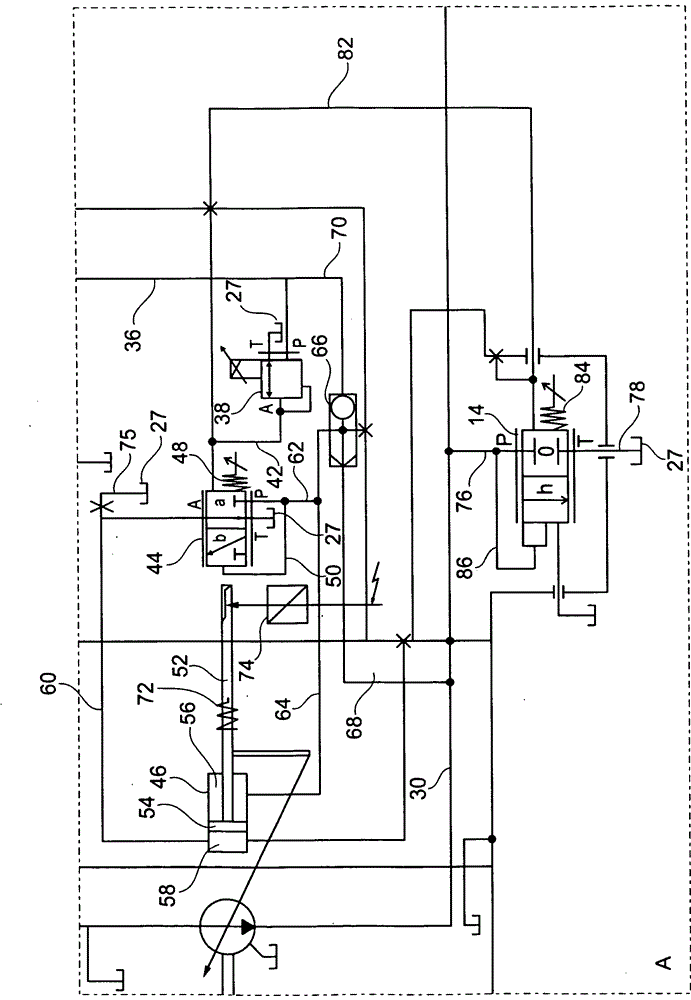

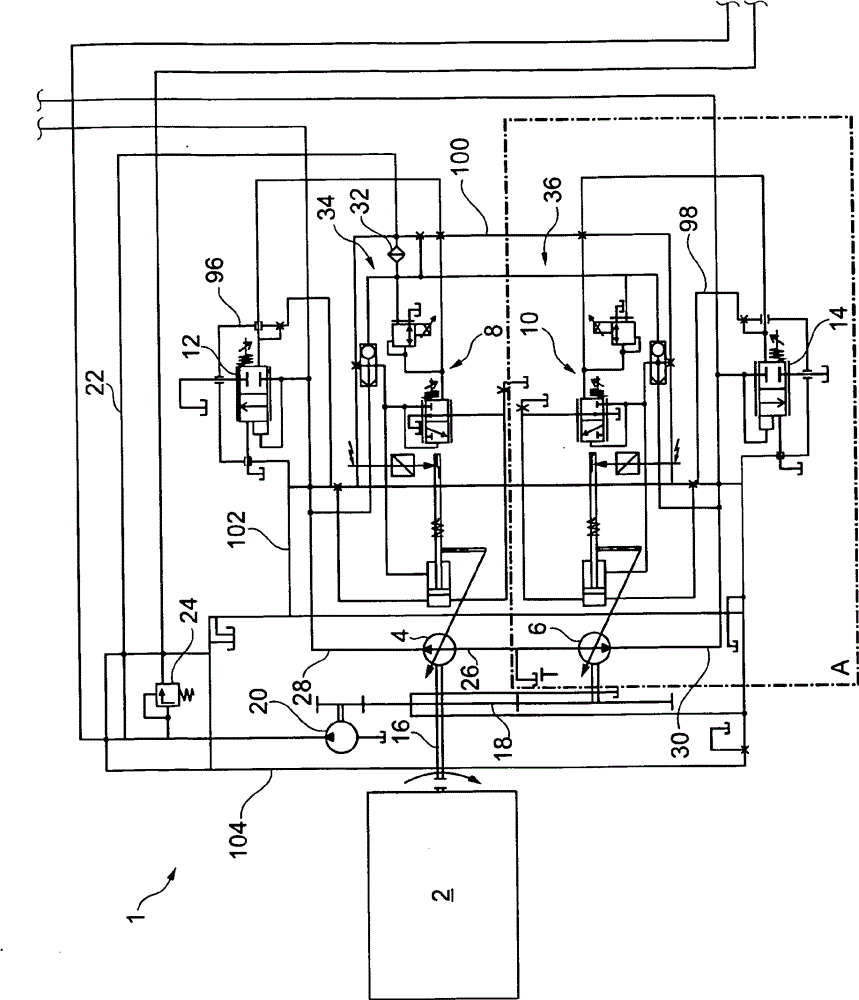

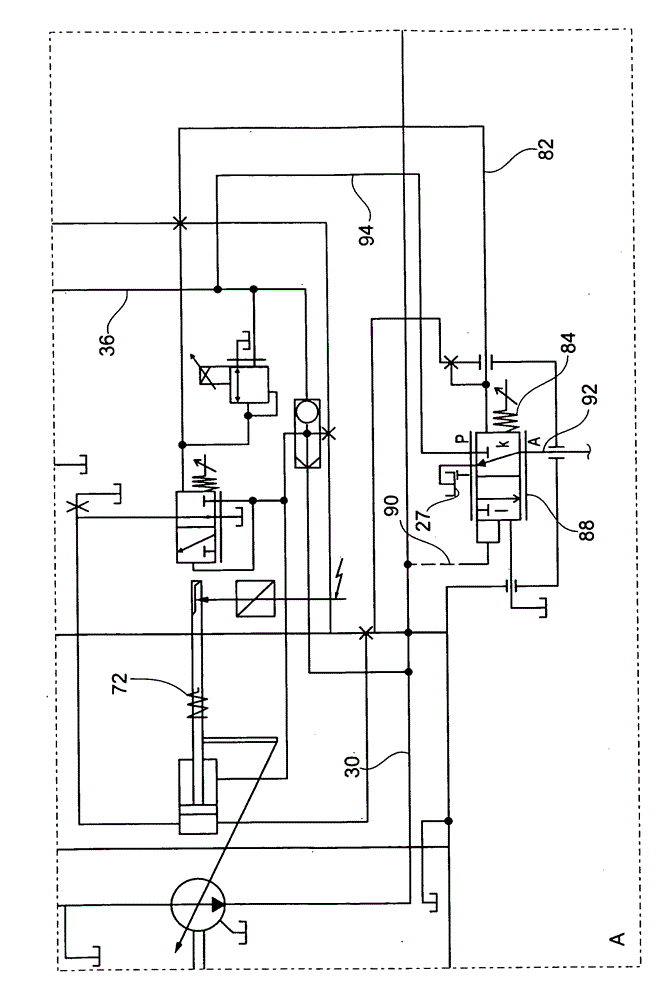

[0024] figure 1 A schematic circuit diagram of a hydraulic system 1 according to the invention is shown according to a first exemplary embodiment. The hydraulic system has two servo pumps or servo variable pumps 4 , 6 , which are driven by a drive unit 2 , and are used to supply pump pressure or output pressure to loads (not shown). The pump regulators 8, 10 are used to control the servo pumps 4, 6, respectively. In order to reduce the respective output pressure as a function of the pressure difference between the nominal pressure and the output pressure, each servo pump 4 and 6 is equipped with a comparator valve or injection valve 12 or 14 .

[0025] The design and hydraulic connections of the servo pumps 4 and 6 to the respective pump regulator 8 or 10 and to the respective comparator valve 12 or 14 are identical in terms of device technology, so for the sake of clarity the following reference is mainly made to the figure 1 The servo pump 6 shown below is used to illustra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com