Method and system for exposing delicate structures of a device encapsulated in a mold compound

A control mechanism and laser beam technology, which is applied in manufacturing tools, welding/welding/cutting objects, semiconductor/solid-state device manufacturing, etc., can solve the problems of energy inconcentration, damage of sensitive IC components, IC chip damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

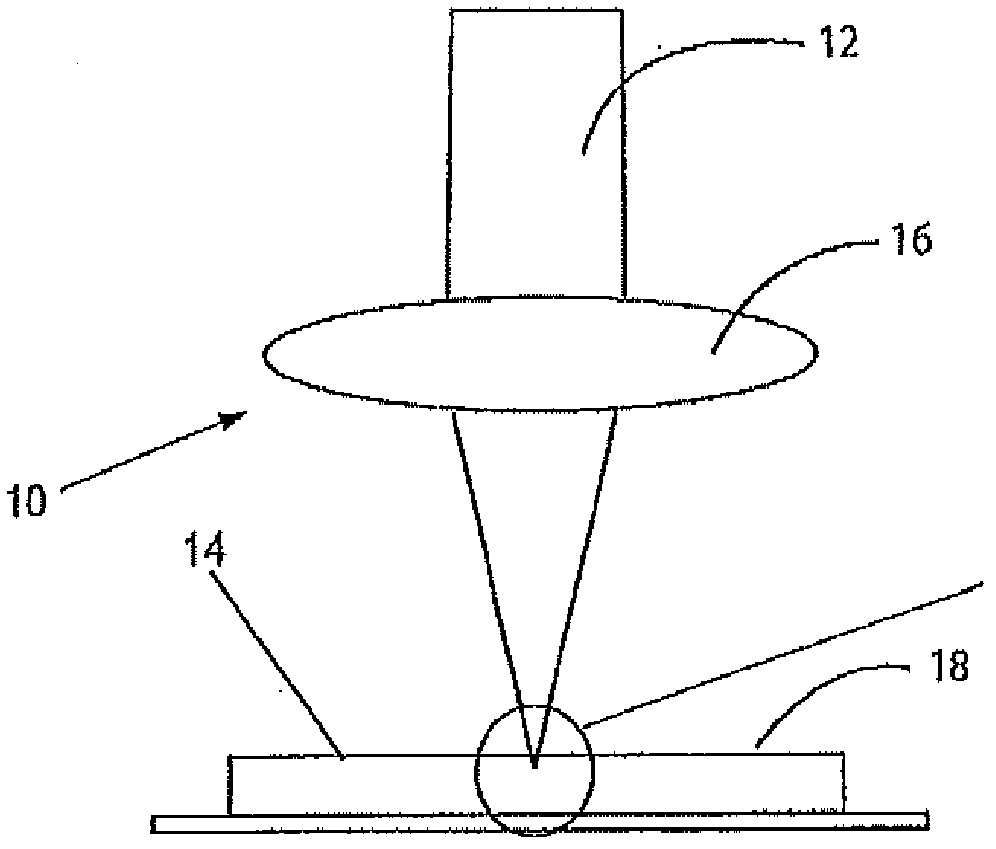

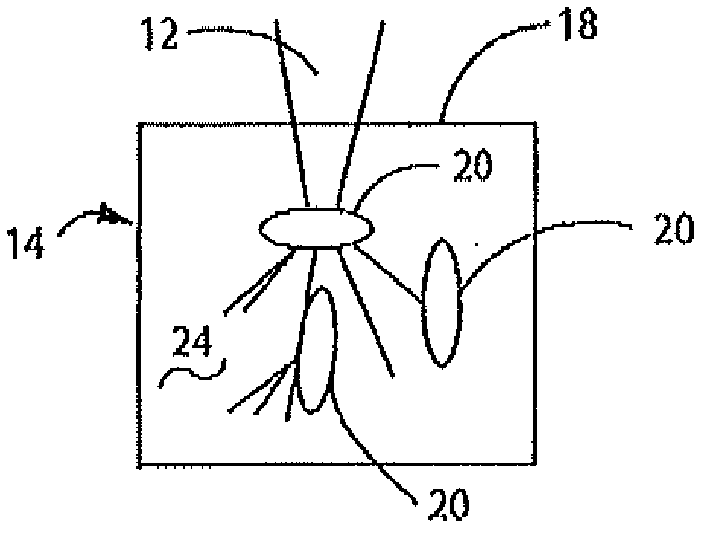

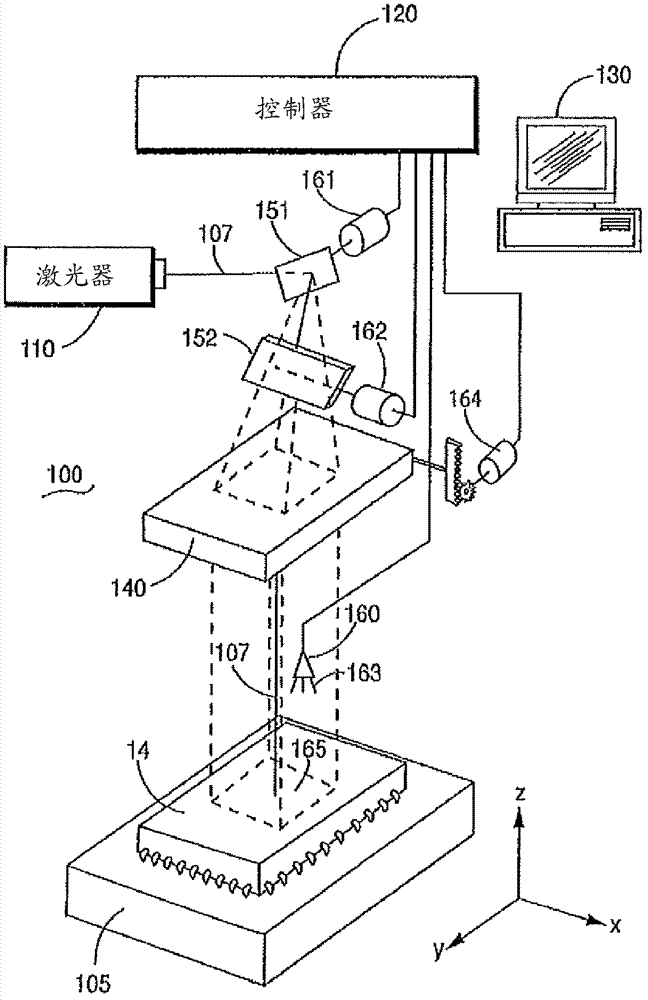

[0015] image 3 is a block diagram of an exemplary embodiment of a system 100 in accordance with the present invention. The device to be analyzed, such as an integrated circuit (IC) 14, is placed on a platform 105 where a laser beam 107 generated by a laser 110 is steered and focused by a pair of reflective blades 151 and 152 and a lens element 140 . Operation is controlled by a controller 120, which may be connected to a user interface 130 for human-computer interaction. For example, controller 120 and user interface 130 may be part of a workstation, personal computer, etc., or may be housed separately.

[0016] During operation, IC 14 remains stationary while light beam 107 is moved in a selective manner over selected portions of the IC surface. At any one time, laser beam 107 impinges on a point on the surface of IC 101 . To the naked eye, however, the laser beam looks like a straight line or a rectangle on the surface of the IC 101 , depending on how fast the laser bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com