Coal and firewood dual-purpose energy-saving and environmental protection sterilizing pot

An energy-saving, environmental-friendly, sterilizing pot technology, applied in application, food preservation, food science and other directions, can solve the problems of low utilization rate of heat energy of steam boilers, increase investment costs, increase equipment investment, etc., and achieve full combustion and large heating area. , the effect of high heat absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

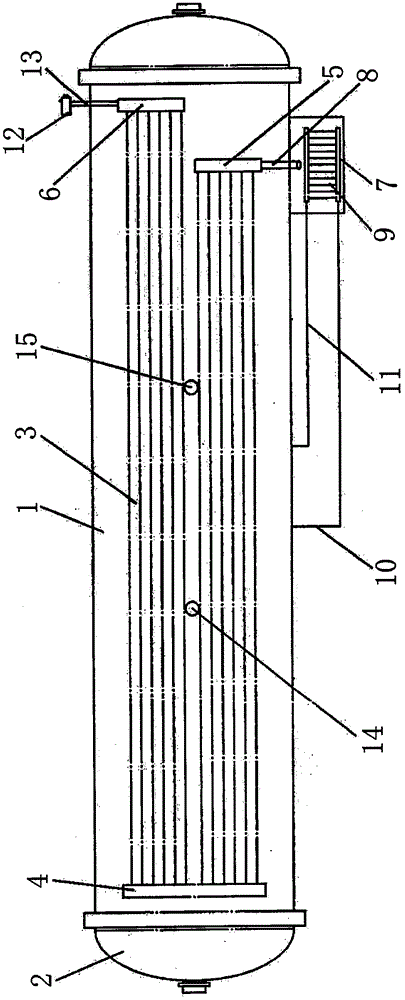

[0009] Such as figure 1 As shown, the present invention is respectively provided with end caps 2 at both ends of the cylinder body 1, and a plurality of heat dissipation pipes 3 are tiled at the bottom of the inner cavity of the cylinder body 1, and one end of the plurality of heat dissipation pipes 3 is connected through the first heat dissipation box 4 Together, the other end of the plurality of heat radiation pipes 3 is connected with the second heat dissipation box 5 and the third heat dissipation box 6, the combustion furnace 7 is located on one side of the cylinder body 1, and the furnace of the combustion furnace 7 passes through the heating air duct 8 and the The second cooling box 5 is connected, and the hollow furnace bar 9 of the combustion furnace 7 is connected with the bottom of the cylinder body 1 through the circulating water inlet pipe 10 and the circulating water outlet pipe 11, and the exhaust fan 12 is connected together with the third cooling box 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com