Aluminum guide rod forming device

A technology of aluminum guide rods and guide rails, which is applied in the field of aluminum guide rod forming devices, can solve the problems of length limitation and low yield of aluminum guide rods in one-time casting, and achieve the effects of low cost, few defects such as slag inclusions, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

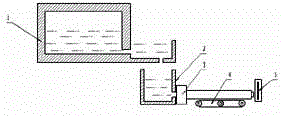

[0015] A kind of aluminum guide rod casting device, it comprises melting furnace 1, as figure 1 As shown: a filter box 2 is connected to the lower part of the smelting furnace 1, and a crystallizer 3, a circular conveyor belt 4 and a synchronous saw 5 are connected to the rear of the filter box 2 in sequence.

[0016] A dummy bar is arranged between the crystallizer 3 and the endless conveyor belt 4 , and guide rails are fixed on the endless conveyor belt 4 .

[0017] There are two crystallizers 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com