Sludge processing technology by electrochemical direct oxidation

A treatment process and electrochemical technology, applied in the field of electrochemical direct oxidation sludge treatment process, to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

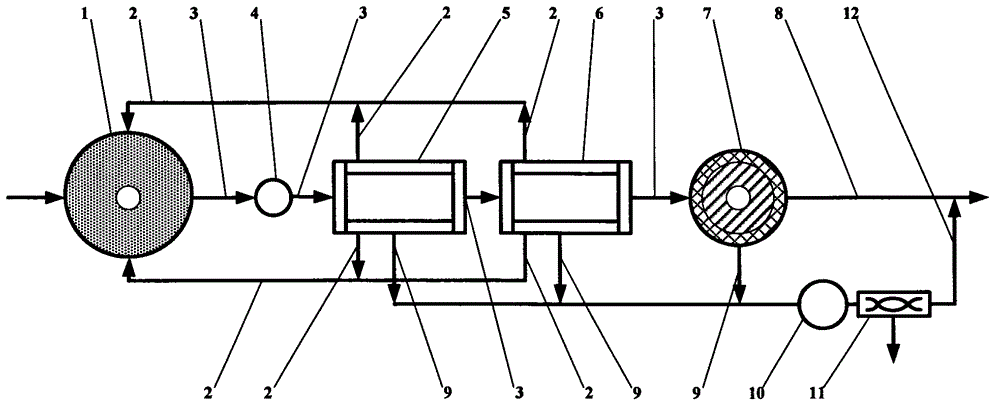

Method used

Image

Examples

Embodiment

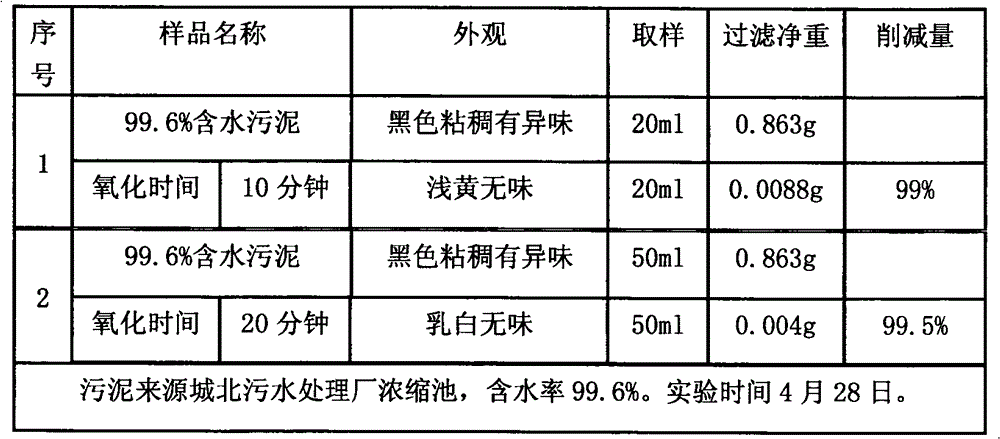

[0025] Experimental equipment: two sets of electrochemical oxidation reaction processors with an effective volume of 0.3L

[0026] One DC power supply

[0027] Sludge pump N: 0.37kw, Q: 0.5-2m 3 / h two

[0028] One solid-liquid separator

[0029] Analytical instrument: 10,000-level electronic balance

[0030] infrared oven

[0031] Water circulation vacuum pump

[0032] Sludge source: Changzhou Jiangbian Sewage Treatment Plant

[0033] Experimental steps:

[0034] 1. Start the sludge pump and adjust the flow rate to 0.5m 3 / h, add the wet sludge pump into the reactor until the reactor overflow water level line, turn off the sludge pump, start the DC power supply, restart the sludge pump, continue to work according to the set flow rate, and take a sample after 10 minutes.

[0035] 2. Adjust the flow meter at the outlet of the sludge pump to adjust the flow to 1m 3 / h, sampled after 20 minutes.

[0036] 3. The samples taken are three groups of balanced control samples,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com