Semiconductor monocrystal silicon production process

A production process and technology of single crystal silicon, applied in the field of semiconductor-grade single crystal silicon production process, can solve the problems of difficult control of product quality, easy occurrence of vortex defects, poor uniformity of section resistivity, etc. The uniformity of section resistivity and the effect of speeding up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

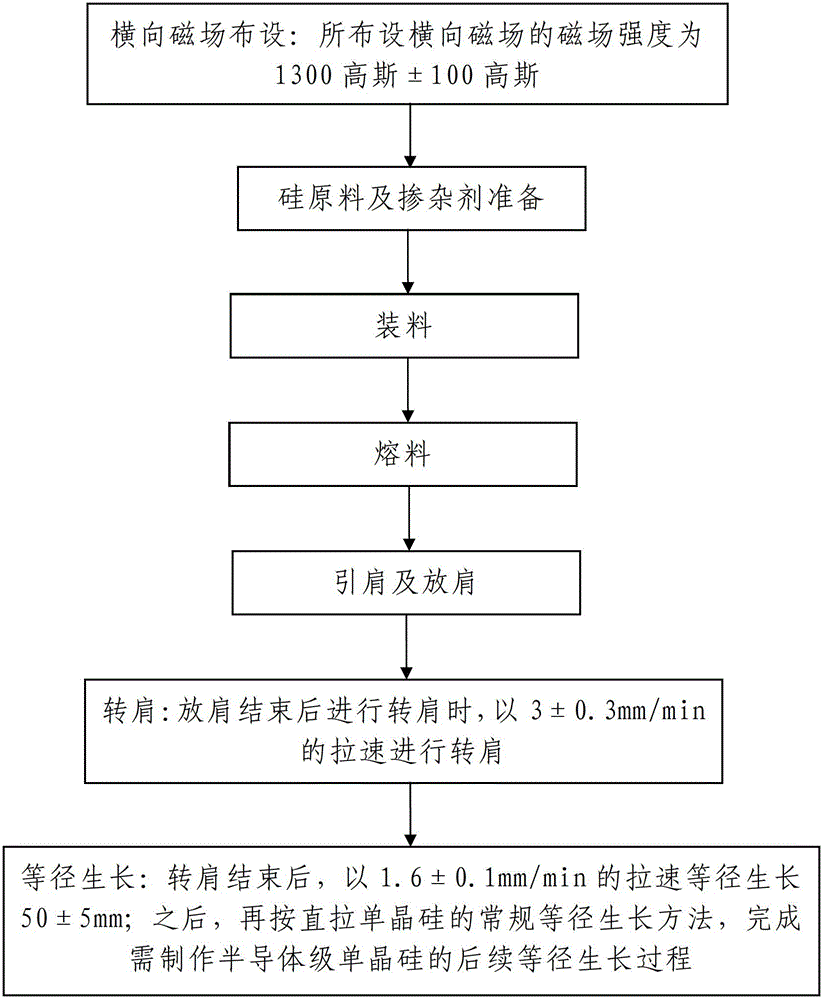

[0038] Such as figure 1 A semiconductor-grade monocrystalline silicon production process shown includes the following steps:

[0039] Step 1. Transverse magnetic field arrangement: a transverse magnetic field is arranged outside the middle part of the main furnace chamber 1 of the single crystal furnace that needs to produce semiconductor-grade single crystal silicon, and the magnetic field strength of the transverse magnetic field is 1300 Gauss ± 100 Gauss. Among them, 1 Gauss = 1 Oersted. It can also be said that the magnetic field strength of the transverse magnetic field is 1300 Oersted±100 Oersteds.

[0040] When the transverse magnetic field is actually laid out, the magnetic field strength of the transverse magnetic field is 1300 Gauss±20 Gauss. In this embodiment, the magnetic field strength of the transverse magnetic field is 1300 Gauss. During actual use, the magnetic field strength of the transverse magnetic field can be adjusted accordingly according to actual ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com