Self-adapting speed regulating device for tunnel boring machine

A speed regulating device and self-adaptive technology, which is applied in driving devices, slitting machinery, earth-moving drilling, etc., can solve the problems of waste of resources, unfavorable continuous mining, and long stopping time interval, so as to improve work efficiency and improve mechanical automation. , the effect of improving work efficiency and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

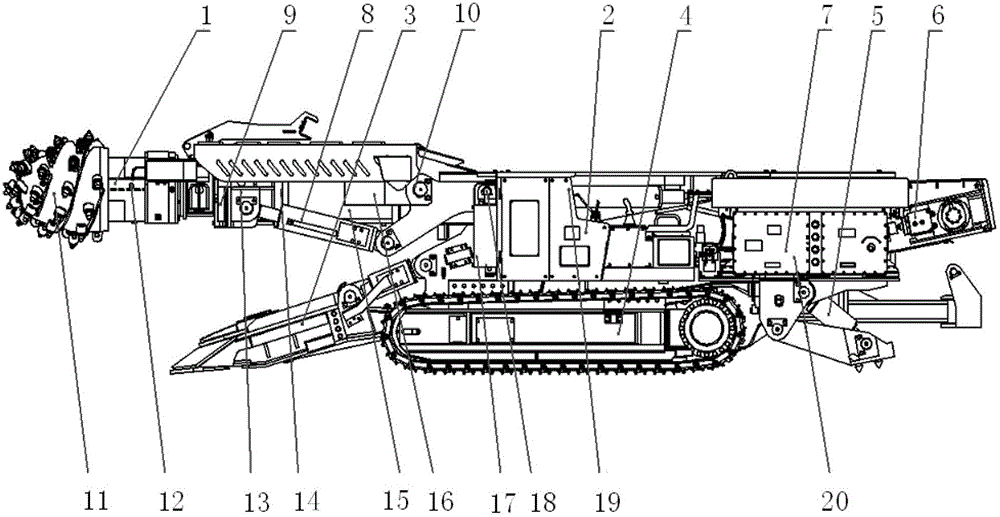

[0011] Such as figure 1 As shown, the roadheader consists of a cutting part 1, a body part 2, a shovel part 3, a walking part 4, a rear support part 5, a first conveyor 6, an electric control system 7, a hydraulic system 8, a water system 9, and a lubrication system 10 composition. The cutting unit 1 includes a cutting head 11, a boom section 12, a reducer 13 and a two-speed cutting motor 15, and the electric control system 7 includes a switch box 20, an operation box 19, a lighting lamp 16, an emergency stop button 18 and a methane sensor 17 A torque sensor 14 is installed between the reducer 13 and the two-speed cutting motor 15, and the torque sensor 14 is electrically connected to the controller of the switch box 20.

[0012] The torque sensor 14 of the adaptive speed regulating device of the roadheader is a mining explosion-proof or intrinsically safe device.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com